Product Overview

The CHDF horizontal multistage stainless steel pump is driven by an extended horizontal shaft motor with an axial inlet and radial outlet layout. Its compact structure is suitable for the stable delivery of clean and mildly corrosive liquids in both industrial and domestic water supply systems.

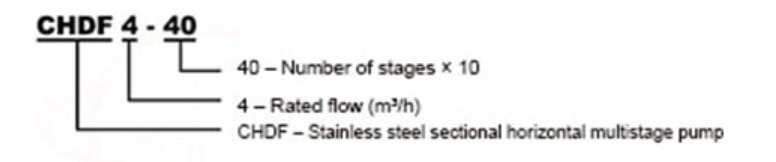

Model Designation

Key Features

-

Horizontal configuration with axial suction and radial discharge, allowing seamless system integration.

-

All wetted components are made of high-quality stainless steel plates using precision stamping and welding, offering excellent corrosion resistance.

-

Multistage hydraulic design enables high head, low noise, and smooth operation.

-

Designed for the efficient transfer of clean or lightly corrosive fluids.

Engineering Summary

This pump series is based on an optimized multistage hydraulic model and manufactured using advanced precision stamping and welding technologies. It delivers high hydraulic efficiency, low energy consumption, compact layout, and easy maintenance, making it ideal for continuous operation across a wide range of conditions.

Typical Applications

Widely applicable in:

-

Air conditioning and cooling water circulation

-

Precision irrigation, dosing and chemical feeding systems

-

Environmental engineering and water purification systems

-

Industrial cleaning and pressure boosting

-

Domestic water supply and aquaculture circulation

-

Customized liquid handling solutions for specific use cases

System & Operation

Components & Supply

-

Rigid coupling between motor and pump ensures structural integrity

-

Balanced multistage impeller layout enhances operational stability

-

Modular design of seals and wetted parts simplifies maintenance

-

Base and bracket structure adaptable to various installation conditions

Technical Specifications

Operating Conditions

-

Liquid temperature range:

• Standard type: −15°C to +70°C

• Hot water type: +70°C to +110°C -

Ambient temperature: ≤ +40°C

-

Max operating pressure: 10 bar

-

Max allowable inlet pressure: limited by system pressure

-

Fluid requirements:

• Clean, low-viscosity, non-flammable, sulfur-free, free of solids and fibers

• Suitable for: mineral water, softened water, purified water, light oils, and weak chemical solutions

• For liquids denser or more viscous than water, a higher-rated motor must be selected

Service Conditions

-

Installation altitude ≤ 1000 meters; higher elevations require custom specification

-

Environment must be free from explosive gases, corrosive vapors, and electromagnetic interference

-

Relative humidity ≤ 95%, ambient temperature ≤ +40°C

-

Install in a well-ventilated, vibration-free, and dry space; outdoor use requires protective enclosure

Protection Functions

-

Motor should include overload protection to prevent damage from abnormal current

-

Dry-run protection is recommended to avoid mechanical seal failure

-

Pressure switches or VFDs should be used to maintain safe operating pressure

-

Check valves and anti-backflow devices help prevent damage due to reverse flow after shutdown

Selection Criteria

-

Select pump model and number of stages based on required flow and head

-

Choose wetted material (e.g., 304 or 316L stainless steel) based on fluid temperature, pH, and chloride content

-

Define sealing type (mechanical or packing) based on fluid corrosiveness

-

Assess installation space and piping layout to confirm compatibility with horizontal structure

-

For fluids with higher viscosity or density than water, a higher power motor should be selected

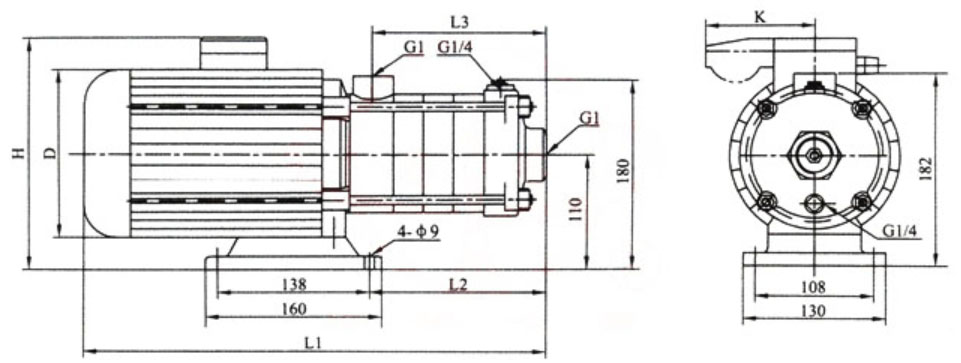

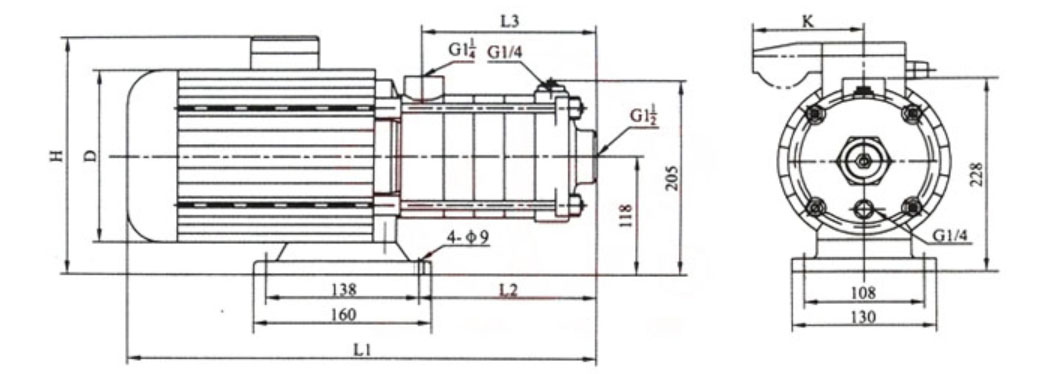

Installation & Dimensions

Outline Drawing

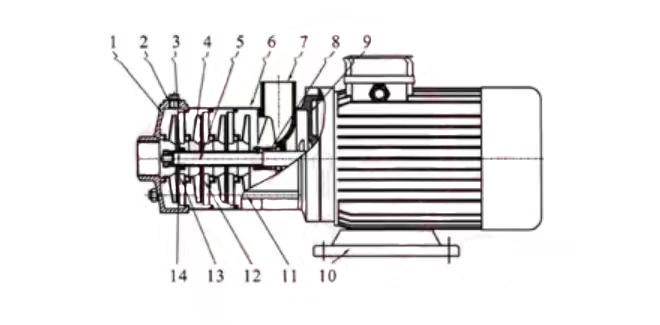

Pump Parts & Materials List

|

Item No.

|

Name

|

Material

|

AISI/ASTM

|

Item No.

|

Name

|

Material

|

AISI/ASTM

|

|

1

|

Suction Casing

|

Stainless Steel

|

AISI304

|

8

|

Mechanical Seal

|

||

|

2

|

End Cover

|

Stainless Steel

|

AISI304

|

9

|

Motor End Cover

|

Aluminum Alloy

|

|

|

3

|

Bearing

|

Tungsten Carbide

|

10

|

Base

|

Cast Iron

|

ASTM258

|

|

|

4

|

Impeller

|

Stainless Steel

|

AISI304

|

11

|

Tie Rod

|

Stainless Steel

|

AISI304

|

|

5

|

Shaft

|

Stainless Steel

|

AISI304

|

12

|

Diffuser

|

Stainless Steel

|

AISI304

|

|

6

|

Discharge Diffuser

|

Stainless Steel

|

AISI304

|

13

|

Support Diffuser

|

Stainless Steel

|

AISI304

|

|

7

|

Discharge Casing

|

Stainless Steel

|

AISI304

|

14

|

Impeller Spacer Sleeve

|

Stainless Steel

|

AISI304

|

Performance Data

|

Model

|

Motor N (KW)

|

Flow Rate Q (m3/h)

|

0.5

|

1.0

|

1.5

|

2.0

|

2.5

|

3.0

|

3.5

|

|

CHDF2-20

|

0.37

|

Head H (m)

|

19

|

18

|

16

|

14

|

13

|

11

|

9

|

|

CHDF2-30

|

0.55

|

Head H (m)

|

28

|

27

|

24

|

21

|

20

|

17

|

14

|

|

CHDF2-40

|

0.55

|

Head H (m)

|

36

|

34

|

32

|

28

|

26

|

23

|

17

|

|

CHDF2-50

|

0.55

|

Head H (m)

|

46

|

43

|

40

|

35

|

33

|

28

|

22

|

|

CHDF2-60

|

0.75

|

Head H (m)

|

54

|

50

|

48

|

42

|

38

|

33

|

25

|

|

Model

|

Motor N (KW)

|

Flow Rate Q (m3/h)

|

1

|

2

|

3

|

4

|

5

|

6

|

7

|

|

CHDF4-20

|

0.55

|

Head H (m)

|

19

|

18

|

16

|

15

|

13

|

10

|

7

|

|

CHDF4-30

|

0.55

|

Head H (m)

|

28

|

27

|

24

|

22

|

19

|

15

|

10

|

|

CHDF4-40

|

0.75

|

Head H (m)

|

38

|

36

|

32

|

30

|

26

|

20

|

14

|

|

CHDF4-50

|

1.1

|

Head H (m)

|

46

|

44

|

41

|

38

|

32

|

26

|

20

|

|

CHDF4-60

|

1.1

|

Head H (m)

|

55

|

53

|

50

|

45

|

37

|

31

|

26

|

|

Model

|

Motor N (KW)

|

Flow Rate Q (m3/h)

|

5

|

6

|

7

|

8

|

9

|

10

|

11

|

|

CHDF8-10

|

0.75

|

Head H (m)

|

9.5

|

9.3

|

9

|

8.5

|

7.5

|

6.5

|

5.5

|

|

CHDF8-20

|

0.75

|

Head H (m)

|

19

|

18.5

|

18

|

17

|

15

|

13

|

11

|

|

CHDF8-30

|

1.1

|

Head H (m)

|

29

|

28

|

27

|

25.5

|

22.5

|

20

|

17.5

|

|

CHDF8-40

|

1.5

|

Head H (m)

|

39

|

38

|

36

|

34

|

30

|

26.5

|

22.5

|

|

CHDF8-50

|

2.2

|

Head H (m)

|

49

|

47

|

45

|

42.5

|

38

|

33.5

|

28

|

|

Model

|

Motor N (KW)

|

Flow Rate Q (m3/h)

|

10

|

12

|

14

|

16

|

18

|

20

|

22

|

|

CHDF16-10

|

1.1

|

Head H (m)

|

12

|

11.5

|

10.5

|

10

|

9

|

7.5

|

6.5

|

|

CHDF16-20

|

2.2

|

Head H (m)

|

24

|

23

|

22

|

21

|

19

|

17

|

14.5

|

|

CHDF16-30

|

3

|

Head H (m)

|

37

|

36

|

34

|

32

|

30

|

27

|

23

|

|

CHDF16-40

|

4

|

Head H (m)

|

50.5

|

49

|

46

|

43

|

40.5

|

36

|

31.5

|

Installation Diagram

|

Model

|

Motor

|

L1(mm)

|

L2(mm)

|

L3(mm)

|

D(mm)

|

H(mm)

|

K(mm)

|

Weight (kg)

|

|

CHDF2-20

|

Single-phase

|

305

|

87

|

84

|

145

|

215/230

|

/96

|

15

|

|

CHDF2-30

|

Single-phase

|

323

|

105

|

102

|

145

|

215/230

|

/96

|

15

|

|

CHDF2-40

|

Single-phase

|

341

|

123

|

120

|

145

|

215/230

|

/96

|

15

|

|

CHDF2-50

|

Single-phase

|

359

|

141

|

138

|

145

|

215/230

|

/96

|

15

|

|

CHDF2-60

|

Single-phase

|

422

|

159

|

156

|

170

|

225/245

|

/100

|

17

|

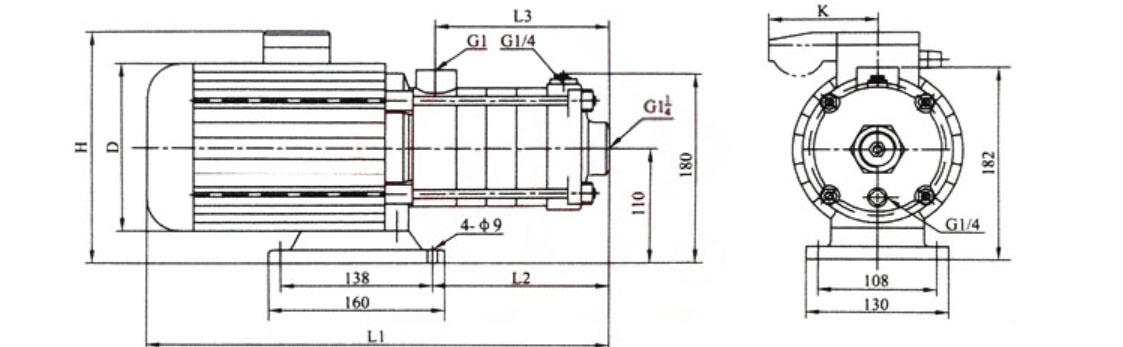

Installation Diagram(2)

|

Model

|

Motor

|

L1(mm)

|

L2(mm)

|

L3(mm)

|

D(mm)

|

H(mm)

|

K(mm)

|

Weight (kg)

|

|

CHDF4-20

|

Single-phase

|

329

|

105

|

102

|

145

|

215/230

|

/96

|

15

|

|

CHDF4-30

|

Single-phase

|

356

|

132

|

129

|

145

|

215/230

|

/96

|

15

|

|

CHDF4-40

|

Single-phase

|

416

|

162

|

156

|

170

|

225/245

|

/100

|

17

|

|

CHDF4-50

|

Single-phase

|

455

|

188

|

183

|

170

|

225/245

|

/100

|

17

|

|

CHDF4-60

|

Single-phase

|

482

|

213

|

210

|

170

|

225/245

|

/100

|

17

|

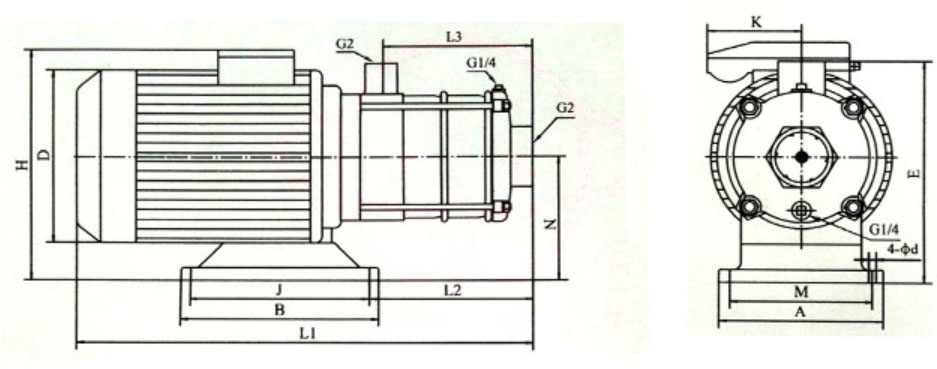

Installation Diagram(3)

| Model |

Motor

|

L1(mm)

|

L2(mm)

|

L3(mm)

|

D(mm)

|

H(mm)

|

K(mm)

|

Weight (kg)

|

|

CHDF8-10

|

Single-phase

|

395

|

126

|

108

|

170

|

230/252

|

/100

|

20

|

|

CHDF8-20

|

Single-phase

|

395

|

126

|

108

|

170

|

230/252

|

/100

|

20

|

|

CHDF8-30

|

Single-phase

|

425

|

156

|

138

|

170

|

230/252

|

/100

|

25

|

|

CHDF8-40

|

Single-phase

|

490

|

186

|

168

|

180

|

240/260

|

/100

|

28

|

|

CHDF8-50

|

Single-phase

|

520

|

216

|

198

|

180

|

240/260

|

/100

|

30

|

Installation Diagram(4)

| Model | Motor | L1 | L2 | L3 | H | D | E | N | A | M | B | j | d | k | Weight (kg) |

| CHDF16-10 | Single-phase | 423 | 151 | 126 | 230/265 | 180 | 227 | 117 | 130 | 108 | 160 | 138 | 9 | /100 | 17.5 |

| CHDF16-20 | Single-phase | 455 | 151 | 126 | 240/270 | 180 | 228 | 118 | 130 | 108 | 160 | 138 | 9 | /100 | 27 |

| CHDF16-30 | Single-phase | 561 | 196 | 171 | 270/ | 195 | 240 | 130 | 130 | 108 | 160 | 138 | 9 | 33 | |

| CHDF16-40 | Single-phase | 621 | 339 | 216 | 270/ | 220 | 230 | 120 | 230 | 109 | 190 | 140 | 12 | 41 | |

OEM & Custom

We offer OEM and customization services for CHDF pumps, including customized nameplates, branding, materials, special voltage/frequency, flange options, performance adjustments, and packaging solutions for overseas distributors and engineering projects.

FAQs

- What liquids can CHDF pumps handle?

CHDF pumps are suitable for clean water and light corrosive liquids such as softened water, pure water, mineral water, and light chemical media. - Can CHDF pumps be used for hot water?

Yes. Hot water models support temperatures up to 110°C. Please specify the medium details when ordering. - Are all wetted parts made of stainless steel?

Yes. The impeller, shaft, casing, and guide vanes are all made of stainless steel (AISI304). - What is the delivery time?

Standard models: 7–15 days. Customized orders: 20–30 days depending on the quantity and specifications. - How do I select the correct CHDF model?

Provide flow rate, head, medium, temperature, and installation information, and we will recommend the most suitable model. - What is the maximum working pressure for CHDF pumps?

The maximum working pressure for CHDF pumps is typically 1.6 MPa, suitable for various medium and low-pressure applications. Specific pressure parameters can be customized based on your needs. - Is the maintenance of CHDF pumps easy?

Yes, CHDF pumps are designed for easy maintenance. Key components such as the impeller and bearings are easy to disassemble and replace, ensuring long-term efficient operation.