Product Overview

The D/DG Series Horizontal Boiler Feed Multistage Pump is a horizontal, single-suction, segmented multistage centrifugal pump designed for clean water and similar liquids under medium to high pressure. Based on a proven multistage hydraulic structure, this series delivers high operating efficiency, wide performance coverage, stable and safe operation, low noise, and long service life, while ensuring ease of installation and maintenance.

These pumps are suitable for conveying non-corrosive liquids with physical and chemical properties similar to clean water, free of solids, abrasives, or suspended matter. With proper selection of wetted materials, sealing configurations, and cooling methods, the pump can also handle oil-bearing media, corrosive fluids, or low-abrasion liquids. The maximum allowable inlet pressure is ≤ 0.6 MPa.

Model Designation

Key Features

-

Efficient multistage hydraulic design providing excellent energy performance across a wide range of duties.

-

Smooth operation with low vibration and noise, making it suitable for applications with stringent environmental requirements.

-

Optional gland packing or mechanical seal configurations offer reliable sealing, reasonable structure, and easy maintenance.

-

Fully enclosed shaft design prevents direct contact with the pumped fluid, reducing corrosion and extending service life.

Engineering Summary

The D/DG Series adopts advanced hydraulic models to maintain efficient and stable performance across wide operating ranges. Stable operation is ensured under both rated and off-design conditions, with low vibration and reduced noise, suitable for systems requiring long-term reliability.

The pump casing is manufactured using standardized processes and assembled under strict quality control to ensure consistent performance and reliability under continuous-duty conditions.

Typical Applications

-

Mine dewatering and oilfield water injection systems

-

Centralized industrial and building water supply

-

Municipal water supply and drainage and long-distance transmission

-

Boiler feedwater systems and high-temperature water transport

-

Suitable for various industrial processes by selecting compatible materials for corrosive or oily fluids

The D Series is suitable for fluids up to 80°C, while the DG Series is optimized for boiler feed applications and supports fluid temperatures up to 105°C.

System & Operation

Components & Supply

-

Suction nozzle arranged horizontally; discharge nozzle arranged vertically upward for convenient system piping.

-

Pump casing sections are tightly clamped with tie bolts, forming a rigid, sealed pressure chamber with high pressure resistance.

-

Multistage impeller assembly is statically balanced to ensure smooth hydraulic flow and stable operation.

-

Flexible coupling connects the pump to the driver motor, compensating for minor misalignments and ensuring smooth power transmission.

Technical Specifications

Operating Conditions

-

Pumped medium should be non-corrosive and free from solids or suspended matter; kinematic viscosity ≤ 150 mm²/s.

-

Maximum inlet pressure: ≤ 0.6 MPa.

-

Medium temperature: D Series ≤ 80°C; DG Series ≤ 105°C.

-

Recommended ambient temperature ≤ 40°C; relative humidity ≤ 95%.

Service Conditions

-

Install in a ventilated, dry indoor environment free from corrosive gases.

-

For outdoor installation, protective covers and sealing measures must be used to prevent water and debris ingress.

-

Foundation must be solid and free from vibration; concrete base with anti-vibration pads is recommended.

-

Reserve adequate space around the equipment for routine inspection and maintenance.

Protection Functions

-

Motor must be equipped with overload, overheat, and phase loss protection.

-

Check valves and pressure relief valves must be installed to prevent backflow and water hammer.

-

Pressure monitoring and alarm systems are recommended to enhance system safety.

-

Dry-running is strictly prohibited; use liquid level interlocks to ensure safe startup.

Selection Criteria

-

Select pump model and number of stages based on required flow and head, ensuring duty point lies within high-efficiency range.

-

Choose appropriate materials and seal types based on medium temperature, corrosiveness, and viscosity.

-

Consider piping layout, motor power, and footprint to ensure installation compatibility.

-

For continuous-duty systems, install standby or parallel pumps to ensure uninterrupted operation.

-

Prioritize standard structures and interchangeable parts to simplify future maintenance and spare parts supply.

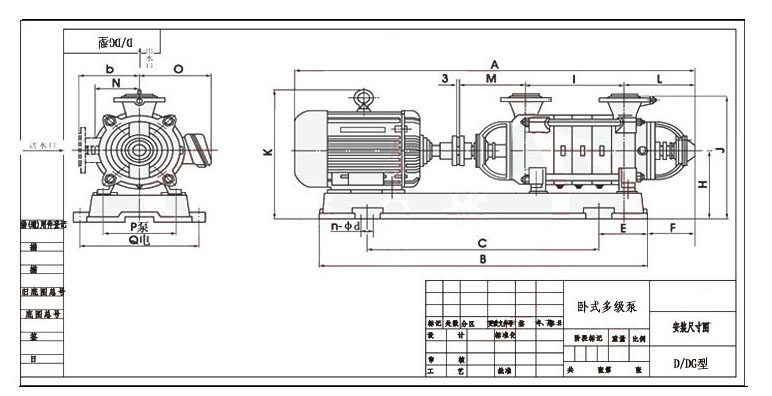

Installation & Dimensions

Outline Drawing

Performance Data

|

1

|

Suction Section

|

2

|

Discharge Section

|

3

|

Middle Section

|

4

|

Diffuser

|

5

|

Impeller

|

6

|

Tail Cover

|

7

|

Seal Ring

|

|

8

|

Diffuser Sleeve

|

9

|

Balance Ring

|

10

|

Balance Disc

|

11

|

Packing Ring

|

12

|

Shaft

|

13

|

Shaft Sleeve A

|

14

|

Shaft Sleeve B

|

|

15

|

Left Bearing Assembly

|

16

|

Right Bearing Assembly

|

17

|

Bearing Collar

|

18

|

Tie Bolt

|

19

|

Packing Gland

|

Performance Parameters

|

Model

|

Rotational Speed

|

Flow Rate

|

Head

|

Efficiency

|

Power (kW) |

NPSHr

|

||

|

(r/min)

|

(m3/h)

|

(L/s)

|

(m)

|

(%)

|

Shaft Power

|

Motor Power

|

(m)

|

|

|

DG6-25×3

|

2950

|

6.3

|

1.75

|

75

|

45

|

2.86

|

5.5

|

2

|

|

DG6-25×4

|

2950

|

6.3

|

1.75

|

100

|

45

|

3.81

|

7.5

|

2

|

|

DG6-25×5

|

2950

|

6.3

|

1.75

|

125

|

45

|

4.77

|

7.5

|

2

|

|

DG6-25×6

|

2950

|

6.3

|

1.75

|

150

|

45

|

5.72

|

11

|

2

|

|

DG6-25×7

|

2950

|

6.3

|

1.75

|

175

|

45

|

6.67

|

11

|

2

|

|

DG6-25×8

|

2950

|

6.3

|

1.75

|

200

|

45

|

7.63

|

15

|

2

|

|

DG6-25×9

|

2950

|

6.3

|

1.75

|

225

|

45

|

8.52

|

15

|

2

|

|

DG6-25×10

|

2950

|

6.3

|

1.75

|

250

|

45

|

9.53

|

18.5

|

2

|

|

DG6-25×11

|

2950

|

6.3

|

1.75

|

275

|

45

|

10.5

|

18.5

|

2

|

|

DG6-25×12

|

2950

|

6.3

|

1.75

|

300

|

45

|

11.44

|

18.5

|

2

|

|

Model

|

Rotational Speed

|

Flow Rate

|

Head

|

Efficiency

|

Power (kW)

|

NPSHr

|

||

|

(r/min)

|

(m3/h)

|

(L/s)

|

(m)

|

(%)

|

Shaft Power

|

Motor Power

|

(m)

|

|

|

DG12-25×3

|

2950

|

12.5

|

3.47

|

75

|

54

|

4.73

|

7.5

|

2

|

|

DG12-25×4

|

2950

|

12.5

|

3.47

|

100

|

54

|

6.3

|

11

|

2

|

|

DG12-25×5

|

2950

|

12.5

|

3.47

|

125

|

54

|

7.88

|

11

|

2

|

|

DG12-25×6

|

2950

|

12.5

|

3.47

|

150

|

54

|

9.46

|

15

|

2

|

|

DG12-25×7

|

2950

|

12.5

|

3.47

|

175

|

54

|

11

|

15

|

2

|

|

DG12-25×8

|

2950

|

12.5

|

3.47

|

200

|

54

|

12.51

|

18.5

|

2

|

|

DG12-25×9

|

2950

|

12.5

|

3.47

|

225

|

54

|

14.18

|

18.5

|

2

|

|

DG12-25×10

|

2950

|

12.5

|

3.47

|

250

|

54

|

15.76

|

22

|

2

|

|

DG12-25×11

|

2950

|

12.5

|

3.47

|

275

|

54

|

17.34

|

22

|

2

|

|

DG12-25×12

|

2950

|

12.5

|

3.47

|

300

|

54

|

18.9

|

30

|

2

|

|

Model

|

Rotational Speed

|

Flow Rate

|

Head

|

Efficiency

|

Power (kW)

|

NPSHr

|

||

|

(r/min)

|

(m3/h)

|

(L/s)

|

(m)

|

(%)

|

Shaft Power

|

Motor Power

|

(m)

|

|

|

DG25-30×3

|

2950

|

25

|

6.94

|

90

|

62

|

9.88

|

15

|

2

|

|

DG25-30×4

|

2950

|

25

|

6.94

|

120

|

62

|

13.1

|

18.5

|

2

|

|

DG25-30×5

|

2950

|

25

|

6.94

|

150

|

62

|

16.47

|

22

|

2

|

|

DG25-30×6

|

2950

|

25

|

6.94

|

180

|

62

|

19.77

|

30

|

2

|

|

DG25-30×7

|

2950

|

25

|

6.94

|

210

|

62

|

23.1

|

30

|

2

|

|

DG25-30×8

|

2950

|

25

|

6.94

|

240

|

62

|

26.4

|

37

|

2

|

|

DG25-30×9

|

2950

|

25

|

6.94

|

270

|

62

|

29.65

|

37

|

2

|

|

DG25-30×10

|

2950

|

25

|

6.94

|

300

|

62

|

32.9

|

4.5

|

2

|

|

Model

|

Rotational Speed

|

Flow Rate

|

Head

|

Efficiency

|

Power (kW)

|

NPSHr

|

||

|

(r/min)

|

(m3/h)

|

(L/s)

|

(m)

|

(%)

|

Shaft Power

|

Motor Power

|

(m)

|

|

|

DG46-30×3

|

2950

|

46

|

12.8

|

90

|

70

|

16.11

|

22

|

3

|

|

DG46-30×4

|

2950

|

46

|

12.8

|

120

|

70

|

21.48

|

30

|

3

|

|

DG46-30×5

|

2950

|

46

|

12.8

|

150

|

70

|

26.85

|

37

|

3

|

|

DG46-30×6

|

2950

|

46

|

12.8

|

180

|

70

|

32.21

|

37

|

3

|

|

DG46-30×7

|

2950

|

46

|

12.8

|

210

|

70

|

37.58

|

45

|

3

|

|

DG46-30×8

|

2950

|

46

|

12.8

|

240

|

70

|

42.95

|

55

|

3

|

|

DG46-30×9

|

2950

|

46

|

12.8

|

270

|

70

|

48.32

|

55

|

3

|

|

DG46-30×10

|

2950

|

46

|

12.8

|

300

|

70

|

53.69

|

75

|

3

|

|

Model

|

Rotational Speed

|

Flow Rate

|

Head

|

Efficiency

|

Power (kW)

|

NPSHr | ||

|

(r/min)

|

(m3/h)

|

(L/s)

|

(m)

|

(%)

|

Shaft Power

|

Motor Power |

(m)

|

|

|

DG46-50×3

|

2950

|

46

|

12.8

|

150

|

63

|

29.83

|

37

|

3

|

|

DG46-50×4

|

2950

|

46

|

12.8

|

200

|

63

|

39.77

|

45

|

3

|

|

DG46-50×5

|

2950

|

46

|

12.8

|

250

|

63

|

49.71

|

55

|

2.8

|

|

DG46-50×6

|

2950

|

46

|

12.8

|

300

|

63

|

59.65

|

75

|

2.8

|

|

DG46-50×7

|

2950

|

46

|

12.8

|

350

|

63

|

69.6

|

90

|

2.8

|

|

DG46-50×8

|

2950

|

46

|

12.8

|

400

|

63

|

79.54

|

90

|

2.8

|

|

DG46-50×9

|

2950

|

46

|

12.8

|

450

|

63

|

89.48

|

110

|

2.8

|

|

DG46-50×10

|

2950

|

46

|

12.8

|

500

|

63

|

99.42

|

110

|

2.8

|

|

DG46-50×11

|

2950

|

46

|

12.8

|

550

|

63

|

109.36

|

132

|

2.8

|

|

DG46-50×12

|

2950

|

46

|

12.8

|

600

|

63

|

119.3

|

132

|

2.8

|

Installation Diagram

Performance Data

| Model |

A

|

B

|

C

|

E

|

F

|

L

|

I

|

M

|

N

|

O

|

H

|

J

|

b

|

K

|

P

|

Q

|

n-φd

|

|

DG6-25×3

|

1175

|

885

|

600

|

145

|

192

|

250

|

180

|

265

|

135

|

210

|

230

|

440

|

170

|

413

|

390

|

390

|

4-φ24

|

|

DG6-25×4

|

1225

|

985

|

650

|

195

|

142

|

250

|

230

|

265

|

135

|

210

|

230

|

400

|

170

|

413

|

390

|

390

|

4-φ24

|

|

DG6-25×5

|

1275

|

985

|

650

|

195

|

192

|

250

|

280

|

265

|

135

|

210

|

230

|

400

|

170

|

413

|

390

|

390

|

4-φ24

|

|

DG6-25×6

|

1450

|

1205

|

785

|

245

|

141

|

250

|

330

|

265

|

165

|

255

|

240

|

410

|

170

|

465

|

435

|

435

|

4-φ24

|

|

DG6-25×7

|

1500

|

1205

|

785

|

245

|

191

|

250

|

380

|

265

|

165

|

255

|

240

|

410

|

170

|

465

|

435

|

435

|

4-φ24

|

|

DG6-25×8

|

1550

|

1305

|

835

|

295

|

141

|

250

|

430

|

265

|

165

|

255

|

240

|

410

|

170

|

465

|

435

|

435

|

4-φ24

|

|

DG6-25×9

|

1600

|

1305

|

835

|

295

|

191

|

250

|

480

|

265

|

165

|

255

|

240

|

410

|

170

|

465

|

435

|

435

|

4-φ24

|

|

DG6-25×10

|

1695

|

1500

|

935

|

370

|

91

|

250

|

530

|

265

|

165

|

255

|

240

|

410

|

170

|

465

|

435

|

435

|

4-φ24

|

|

DG6-25×11

|

1745

|

1500

|

935

|

370

|

141

|

250

|

580

|

265

|

165

|

255

|

240

|

410

|

170

|

465

|

435

|

435

|

4-φ24

|

|

DG6-25×12

|

1795

|

1500

|

935

|

370

|

191

|

250

|

630

|

265

|

165

|

255

|

240

|

410

|

170

|

465

|

435

|

435

|

4-φ24

|

|

Model

|

A

|

B

|

C

|

E

|

F

|

L

|

I

|

M

|

N

|

O

|

H

|

J

|

b

|

K

|

P

|

Q

|

n-φd

|

|

DG12-25×3

|

1175

|

874

|

600

|

140

|

180

|

250

|

180

|

265

|

135

|

210

|

230

|

400

|

170

|

413

|

395

|

295

|

4-φ25

|

|

DG12-25×4

|

1350

|

1040

|

710

|

165

|

183

|

250

|

230

|

265

|

165

|

255

|

240

|

410

|

170

|

465

|

430

|

430

|

4-φ25

|

|

DG12-25×5

|

1400

|

1090

|

730

|

190

|

183

|

250

|

280

|

265

|

165

|

255

|

240

|

410

|

170

|

465

|

430

|

430

|

4-φ25

|

|

DG12-25×6

|

1450

|

1140

|

740

|

232

|

183

|

250

|

330

|

265

|

165

|

255

|

240

|

410

|

170

|

465

|

430

|

430

|

4-φ25

|

|

DG12-25×7

|

1500

|

1190

|

780

|

242

|

183

|

250

|

380

|

265

|

165

|

255

|

240

|

410

|

170

|

465

|

430

|

430

|

4-φ25

|

|

DG12-25×8

|

1595

|

1284

|

830

|

266

|

183

|

250

|

430

|

265

|

165

|

255

|

240

|

410

|

170

|

465

|

430

|

430

|

4-φ25

|

|

DG12-25×9

|

1645

|

1334

|

850

|

294

|

183

|

250

|

840

|

265

|

165

|

255

|

240

|

410

|

170

|

465

|

430

|

430

|

4-φ25

|

|

DG12-25×10

|

1720

|

1397

|

870

|

327

|

172

|

250

|

530

|

265

|

180

|

285

|

260

|

430

|

170

|

510

|

400

|

460

|

4-φ25

|

|

DG12-25×11

|

1770

|

1447

|

900

|

347

|

172

|

250

|

580

|

265

|

180

|

285

|

260

|

430

|

170

|

510

|

400

|

460

|

4-φ25

|

|

DG12-25×12

|

1925

|

1571

|

980

|

371

|

176

|

250

|

633

|

265

|

200

|

310

|

260

|

450

|

170

|

555

|

400

|

500

|

4-φ25

|

|

Model

|

A

|

B

|

C

|

E

|

F

|

L

|

I

|

M

|

N

|

O

|

H

|

J

|

b

|

K

|

P

|

Q

|

n-φd

|

|

DG25-30×3

|

1450

|

1110

|

760

|

185

|

227

|

285

|

230

|

330

|

165

|

255

|

250

|

460

|

210

|

475

|

460

|

460

|

4-φ30

|

|

DG25-30×4

|

1560

|

1219

|

850

|

204

|

228

|

285

|

295

|

330

|

165

|

255

|

250

|

460

|

210

|

475

|

460

|

460

|

4-φ30

|

|

DG25-30×5

|

1650

|

1297

|

880

|

237

|

228

|

285

|

360

|

330

|

180

|

285

|

260

|

470

|

210

|

510

|

460

|

460

|

4-φ30

|

|

DG25-30×6

|

1825

|

1432

|

970

|

262

|

225

|

285

|

425

|

330

|

200

|

310

|

280

|

490

|

210

|

555

|

460

|

505

|

4-φ30

|

|

DG25-30×7

|

1885

|

1497

|

1000

|

297

|

225

|

285

|

490

|

330

|

200

|

310

|

280

|

490

|

210

|

555

|

460

|

505

|

4-φ30

|

|

DG25-30×8

|

1950

|

1562

|

1030

|

332

|

225

|

285

|

555

|

330

|

200

|

310

|

280

|

490

|

210

|

555

|

460

|

505

|

4-φ30

|

|

DG25-30×9

|

2015

|

1627

|

1080

|

347

|

225

|

285

|

620

|

330

|

200

|

310

|

280

|

490

|

210

|

555

|

460

|

505

|

4-φ30

|

|

DG25-30×10

|

2150

|

1728

|

1120

|

398

|

222

|

285

|

685

|

330

|

225

|

345

|

305

|

515

|

210

|

610

|

540

|

460

|

4-φ30

|

|

Model

|

A

|

B

|

C

|

E

|

F

|

L

|

I

|

M

|

N

|

O

|

H

|

J

|

b

|

K

|

P

|

Q

|

n-φd

|

|

DG46-30×3

|

1520

|

1167

|

845

|

130

|

228

|

285

|

230

|

330

|

180

|

285

|

260

|

470

|

210

|

510

|

460

|

460

|

4-φ30

|

|

DG46-30×4

|

1690

|

1302

|

850

|

242

|

225

|

285

|

295

|

330

|

200

|

310

|

280

|

490

|

210

|

555

|

460

|

505

|

4-φ30

|

|

DG46-30×5

|

1755

|

1367

|

910

|

247

|

225

|

285

|

360

|

330

|

200

|

310

|

280

|

490

|

210

|

555

|

460

|

505

|

4-φ30

|

|

DG46-30×6

|

1820

|

1432

|

935

|

287

|

225

|

285

|

425

|

330

|

200

|

310

|

280

|

490

|

210

|

555

|

460

|

505

|

4-φ30

|

|

DG46-30×7

|

1925

|

1532

|

1010

|

302

|

223

|

285

|

490

|

330

|

225

|

345

|

305

|

515

|

210

|

610

|

460

|

545

|

4-φ30

|

|

DG46-30×8

|

2105

|

1694

|

1110

|

349

|

221

|

285

|

555

|

330

|

250

|

385

|

330

|

540

|

210

|

655

|

460

|

594

|

4-φ30

|

|

DG46-30×9

|

2170

|

1759

|

1140

|

384

|

221

|

285

|

620

|

330

|

250

|

385

|

330

|

540

|

210

|

655

|

460

|

594

|

4-φ30

|

|

DG46-30×10

|

2305

|

1897

|

1245

|

402

|

219

|

285

|

685

|

330

|

280

|

410

|

360

|

570

|

210

|

720

|

460

|

650

|

4-φ30

|

|

Model

|

A

|

B

|

C

|

E

|

F

|

L

|

I

|

M

|

N

|

O

|

H

|

J

|

b

|

K

|

P

|

Q

|

n-φd

|

|

DG46-50×3

|

1717

|

1317

|

875

|

215

|

246

|

339

|

245

|

353

|

200

|

310

|

360

|

630

|

300

|

635

|

500

|

500

|

4-φ24

|

|

DG46-50×4

|

1817

|

1415

|

925

|

293

|

246

|

339

|

305

|

353

|

225

|

345

|

420

|

690

|

300

|

725

|

500

|

500

|

4-φ24

|

|

DG46-50×5

|

1992

|

1571

|

1020

|

341

|

240

|

339

|

365

|

353

|

250

|

385

|

420

|

690

|

300

|

745

|

500

|

600

|

4-φ24

|

|

DG46-50×6

|

2122

|

1758

|

1130

|

321

|

180

|

339

|

425

|

353

|

280

|

410

|

420

|

690

|

300

|

780

|

500

|

650

|

6-φ24

|

|

DG46-50×7

|

2182

|

1758

|

1130

|

321

|

240

|

339

|

485

|

353

|

280

|

410

|

420

|

690

|

300

|

780

|

500

|

650

|

6-φ24

|

|

DG46-50×8

|

2292

|

1869

|

1180

|

331

|

240

|

339

|

545

|

353

|

280

|

410

|

420

|

690

|

300

|

780

|

500

|

650

|

6-φ24

|

|

DG46-50×9

|

2473

|

2046

|

1330

|

360

|

166

|

339

|

605

|

353

|

323

|

550

|

515

|

785

|

300

|

970

|

500

|

750

|

6-φ24

|

|

DG46-50×10

|

2533

|

2046

|

1330

|

360

|

226

|

339

|

665

|

353

|

323

|

550

|

515

|

785

|

300

|

970

|

500

|

750

|

6-φ24

|

|

DG46-50×11

|

2641

|

2222

|

1480

|

370

|

166

|

339

|

725

|

353

|

323

|

550

|

515

|

785

|

300

|

970

|

500

|

750

|

6-φ24

|

|

DG46-50×12

|

2701

|

2222

|

1480

|

370

|

226

|

339

|

785

|

353

|

323

|

550

|

515

|

785

|

300

|

970

|

500

|

750

|

6-φ24

|

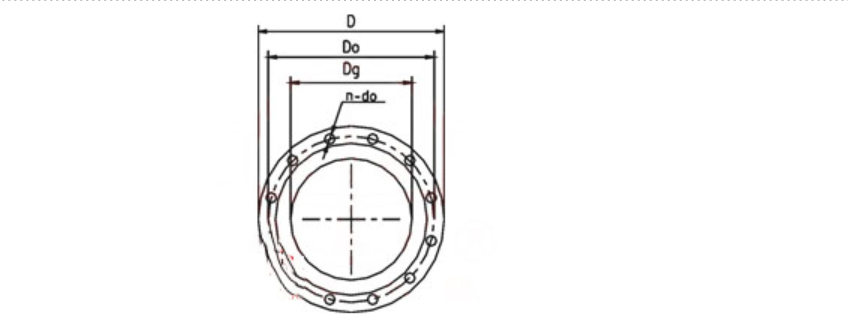

Outline Drawing(2)

Installation Dimensions

|

Dimensions

|

Suction Flange

|

Discharge Flange

|

||||||

|

Model

|

Dg

|

Do

|

D

|

n-do

|

Dg

|

Do

|

D

|

n-do

|

|

D6-25

DG6-25 |

40

|

100

|

130

|

4-φ13.5

|

40

|

110

|

150

|

4-φ17.5

|

|

D12-25

DG12-25 |

50

|

110

|

140

|

4-φ13.5

|

40

|

110

|

150

|

4-φ17.5

|

|

D25-30

DG25-30 |

65

|

130

|

160

|

4-φ17.5

|

65

|

145

|

185

|

8-φ17.5

|

|

D46-30

DG46-30 |

80

|

150

|

190

|

4-φ17.5

|

65

|

145

|

185

|

8-φ17.5

|

|

D46-50

DG46-50 |

80

|

150

170 |

190

215 |

4-φ17.5

8-φ22 |

80

|

170

|

215

|

8-φ22

|

OEM & Custom

Customization includes pump materials, shaft seal types, flange standards, voltage/frequency options, OEM branding, color customization, and documentation for international engineering projects.

FAQs for Oversea Buyers

- What is the delivery time?

Standard models ship in 10–20 days; customized orders typically require 20–30 days, depending on order quantity and specific requirements. - Can the pump be used for hot water?

Yes, DG models support hot water up to 105°C with the appropriate material configuration. - Do you offer OEM customization?

Yes, we offer OEM customization services, including nameplates, color options, manuals, packaging, and performance adjustments to meet specific customer needs. - What voltage options are available?

We fully support 220V, 380V, 415V, 440V voltages, and 50/60Hz frequencies, complying with international standards. - What liquids can the pump handle?

The pump is suitable for clean water or similar liquids; for corrosive or abrasive media, material upgrades are available to meet specific requirements. - What is the service life of the pump?

The designed service life of the pump can exceed 10 years, depending on the operating environment and maintenance practices. Regular maintenance and inspections can significantly extend the operational life. - How does our pump improve efficiency and save energy?

Our pumps use advanced hydraulic designs to significantly enhance efficiency, while reducing energy consumption, helping you save on long-term operational costs.