Product Overview

The D/DG Series Horizontal Multistage Clean Water Pumps are high-efficiency centrifugal pumps designed with a horizontal, single-suction, multistage configuration. These pumps feature advanced hydraulic modeling and are characterized by high efficiency, wide operational performance ranges, low noise, long service life, and ease of installation and maintenance. They are suitable for transporting clean water or other liquids with similar physical and chemical properties to water, widely used in industrial and municipal water supply systems.

Model Designation

Key Features

-

High-efficiency hydraulic design, offering a wide performance range.

-

Low noise, smooth operation, and high long-term reliability.

-

Shaft sealing options include packing seals or mechanical seals, which are mature designs and easy to maintain.

-

Fully separated shaft and media design, providing excellent wear resistance, corrosion resistance, and an extended service life.

Engineering Overview

The D/DG Series pumps feature a multistage segmented structure and are designed with optimized hydraulic performance. They are adaptable to various media and temperature conditions, such as hot water, oils, and slightly corrosive or abrasive liquids. The pumps allow a maximum inlet pressure of up to 0.6 MPa, meeting common engineering application requirements.

Typical Applications

The D/DG Series Horizontal Multistage Clean Water Pumps are widely used in:

-

Industrial and municipal water supply and drainage systems.

-

Mining drainage.

-

Oilfield water injection (depending on material selection for corrosive environments).

-

Boiler feed water systems (with medium temperature ≤ 105°C).

System Configuration

The D/DG Series pump system mainly consists of the following components:

-

Stationary Components: Suction part, intermediate part, guide rail, and discharge part, clamped together with bolted connections to form the working chamber.

-

Rotating Components: Shaft, impeller, balance disk, and shaft sleeve; axial thrust is balanced by the balance disk.

-

Bearing Support: The lower end is supported by water-lubricated bearings; the upper end is supported by angular contact ball bearings.

-

Axial Force Balance: Primarily absorbed by the balance disk, with residual axial force handled by angular contact bearings.

-

Sealing System: Includes packing box, packing rings, and lantern rings (standard configuration).

Components and Supply

The D/DG Series pump system includes:

-

Pump Casing: Vertical multistage pipe structure with co-axial inlet and outlet.

-

Rotor Assembly: Includes direct-impeller, shaft, balance disk, and shaft sleeve.

-

Shaft Sealing System: Includes packing box and mechanical seals.

-

Installation Accessories: Includes base fasteners, foundation nuts, and optional protective covers.

Technical Service

The D/DG Series pumps offer comprehensive technical support and services, including installation commissioning, operation monitoring, and maintenance advice. We provide detailed operation manuals and remote technical support to ensure high efficiency and longevity.

Operating Conditions

-

Pumped Media: Clean water or liquids with properties similar to water.

-

Maximum Inlet Pressure: ≤0.6 MPa.

-

Medium Temperature Range:

-

General Service: ≤80°C.

-

Boiler Feed Water Service: ≤105°C.

-

-

Ambient Conditions: Ambient temperature ≤40°C, relative humidity ≤95%.

Service Conditions

-

Regular Monitoring: Check bearing temperature, ensuring the temperature rise does not exceed 35°C above ambient temperature, with a maximum temperature not exceeding 75°C.

-

Maintenance Logic: Periodically inspect seals, bearings, and worn components to maintain stable system performance.

Protection Features

The D/DG Series pumps are equipped with various protection features, including overload protection, overpressure protection, and axial force balance, ensuring safe and stable operation under extreme conditions.

Selection Criteria

When selecting the D/DG Series pumps, consider the specific application requirements, required flow rates, and head pressure. Also, take into account long-term system stability and ease of maintenance. The installation space and ease of maintenance should also be considered.

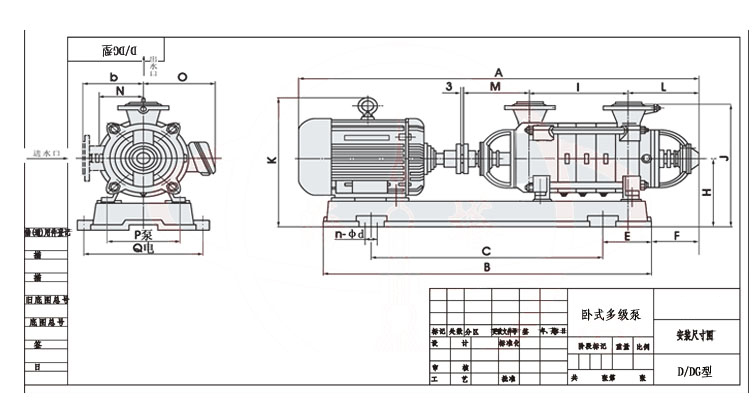

Installation & Dimensions

Outline Drawing

Performance Data

|

1

|

Inlet Casing

|

2

|

Discharge Casing

|

3

|

Middle Casing

|

4

|

Guide Vane

|

5

|

Impeller

|

6

|

Tail Cover

|

7

|

Seal Ring

|

|

8

|

Guide Vane Sleeve

|

9

|

Balance Ring

|

10

|

Balance Disc

|

11

|

Packing Ring

|

12

|

Shaft

|

13

|

Shaft Sleeve A

|

14

|

Shaft Sleeve B

|

|

15

|

Left Bearing Assembly

|

16

|

Right Bearing Assembly

|

17

|

Bearing Retaining Sleeve

|

18

|

Tie Bolt

|

19

|

Packing Gland

|

Performance Parameters

|

Model

|

Speed (rpm)

|

Flow Rate (m³/h)

|

Head (m)

|

Efficiency (%)

|

Power (kW)

|

NPSHr

|

||

|

(r/min)

|

(m3/h)

|

(L/s)

|

(m)

|

(%)

|

Shaft Power

|

Motor Power (kW)

|

(m)

|

|

|

DG6-25×3

|

2950

|

6.3

|

1.75

|

75

|

45

|

2.86

|

5.5

|

2

|

|

DG6-25×4

|

2950

|

6.3

|

1.75

|

100

|

45

|

3.81

|

7.5

|

2

|

|

DG6-25×5

|

2950

|

6.3

|

1.75

|

125

|

45

|

4.77

|

7.5

|

2

|

|

DG6-25×6

|

2950

|

6.3

|

1.75

|

150

|

45

|

5.72

|

11

|

2

|

|

DG6-25×7

|

2950

|

6.3

|

1.75

|

175

|

45

|

6.67

|

11

|

2

|

|

DG6-25×8

|

2950

|

6.3

|

1.75

|

200

|

45

|

7.63

|

15

|

2

|

|

DG6-25×9

|

2950

|

6.3

|

1.75

|

225

|

45

|

8.52

|

15

|

2

|

|

DG6-25×10

|

2950

|

6.3

|

1.75

|

250

|

45

|

9.53

|

18.5

|

2

|

|

DG6-25×11

|

2950

|

6.3

|

1.75

|

275

|

45

|

10.5

|

18.5

|

2

|

|

DG6-25×12

|

2950

|

6.3

|

1.75

|

300

|

45

|

11.44

|

18.5

|

2

|

|

Model

|

Speed (rpm)

|

Flow Rate (m³/h)

|

Head (m)

|

Efficiency (%)

|

Power (kW)

|

NPSHr

|

||

|

(r/min)

|

(m3/h)

|

(L/s)

|

(m)

|

(%)

|

Shaft Power

|

Motor Power (kW)

|

(m)

|

|

|

DG12-25×3

|

2950

|

12.5

|

3.47

|

75

|

54

|

4.73

|

7.5

|

2

|

|

DG12-25×4

|

2950

|

12.5

|

3.47

|

100

|

54

|

6.3

|

11

|

2

|

|

DG12-25×5

|

2950

|

12.5

|

3.47

|

125

|

54

|

7.88

|

11

|

2

|

|

DG12-25×6

|

2950

|

12.5

|

3.47

|

150

|

54

|

9.46

|

15

|

2

|

|

DG12-25×7

|

2950

|

12.5

|

3.47

|

175

|

54

|

11

|

15

|

2

|

|

DG12-25×8

|

2950

|

12.5

|

3.47

|

200

|

54

|

12.51

|

18.5

|

2

|

|

DG12-25×9

|

2950

|

12.5

|

3.47

|

225

|

54

|

14.18

|

18.5

|

2

|

|

DG12-25×10

|

2950

|

12.5

|

3.47

|

250

|

54

|

15.76

|

22

|

2

|

|

DG12-25×11

|

2950

|

12.5

|

3.47

|

275

|

54

|

17.34

|

22

|

2

|

|

DG12-25×12

|

2950

|

12.5

|

3.47

|

300

|

54

|

18.9

|

30

|

2

|

|

Model

|

Speed (rpm)

|

Flow Rate (m³/h)

|

Head (m)

|

Efficiency (%)

|

Power (kW)

|

NPSHr

|

||

|

(r/min)

|

(m3/h)

|

(L/s)

|

(m)

|

(%)

|

Shaft Power

|

Motor Power (kW)

|

(m)

|

|

|

DG25-30×3

|

2950

|

25

|

6.94

|

90

|

62

|

9.88

|

15

|

2

|

|

DG25-30×4

|

2950

|

25

|

6.94

|

120

|

62

|

13.1

|

18.5

|

2

|

|

DG25-30×5

|

2950

|

25

|

6.94

|

150

|

62

|

16.47

|

22

|

2

|

|

DG25-30×6

|

2950

|

25

|

6.94

|

180

|

62

|

19.77

|

30

|

2

|

|

DG25-30×7

|

2950

|

25

|

6.94

|

210

|

62

|

23.1

|

30

|

2

|

|

DG25-30×8

|

2950

|

25

|

6.94

|

240

|

62

|

26.4

|

37

|

2

|

|

DG25-30×9

|

2950

|

25

|

6.94

|

270

|

62

|

29.65

|

37

|

2

|

|

DG25-30×10

|

2950

|

25

|

6.94

|

300

|

62

|

32.9

|

4.5

|

2

|

|

Model

|

Speed (rpm)

|

Flow Rate (m³/h)

|

Head (m)

|

Efficiency (%)

|

Power (kW)

|

NPSHr

|

||

|

(r/min)

|

(m3/h)

|

(L/s)

|

(m)

|

(%)

|

Shaft Power

|

Motor Power (kW)

|

(m)

|

|

|

DG46-30×3

|

2950

|

46

|

12.8

|

90

|

70

|

16.11

|

22

|

3

|

|

DG46-30×4

|

2950

|

46

|

12.8

|

120

|

70

|

21.48

|

30

|

3

|

|

DG46-30×5

|

2950

|

46

|

12.8

|

150

|

70

|

26.85

|

37

|

3

|

|

DG46-30×6

|

2950

|

46

|

12.8

|

180

|

70

|

32.21

|

37

|

3

|

|

DG46-30×7

|

2950

|

46

|

12.8

|

210

|

70

|

37.58

|

45

|

3

|

|

DG46-30×8

|

2950

|

46

|

12.8

|

240

|

70

|

42.95

|

55

|

3

|

|

DG46-30×9

|

2950

|

46

|

12.8

|

270

|

70

|

48.32

|

55

|

3

|

|

DG46-30×10

|

2950

|

46

|

12.8

|

300

|

70

|

53.69

|

75

|

3

|

|

Model

|

Speed (rpm)

|

Flow Rate (m³/h)

|

Head (m)

|

Efficiency (%)

|

Power (kW)

|

NPSHr

|

||

|

(r/min)

|

(m3/h)

|

(L/s)

|

(m)

|

(%)

|

Shaft Power

|

Motor Power (kW)

|

(m)

|

|

|

DG46-50×3

|

2950

|

46

|

12.8

|

150

|

63

|

29.83

|

37

|

3

|

|

DG46-50×4

|

2950

|

46

|

12.8

|

200

|

63

|

39.77

|

45

|

3

|

|

DG46-50×5

|

2950

|

46

|

12.8

|

250

|

63

|

49.71

|

55

|

2.8

|

|

DG46-50×6

|

2950

|

46

|

12.8

|

300

|

63

|

59.65

|

75

|

2.8

|

|

DG46-50×7

|

2950

|

46

|

12.8

|

350

|

63

|

69.6

|

90

|

2.8

|

|

DG46-50×8

|

2950

|

46

|

12.8

|

400

|

63

|

79.54

|

90

|

2.8

|

|

DG46-50×9

|

2950

|

46

|

12.8

|

450

|

63

|

89.48

|

110

|

2.8

|

|

DG46-50×10

|

2950

|

46

|

12.8

|

500

|

63

|

99.42

|

110

|

2.8

|

|

DG46-50×11

|

2950

|

46

|

12.8

|

550

|

63

|

109.36

|

132

|

2.8

|

|

DG46-50×12

|

2950

|

46

|

12.8

|

600

|

63

|

119.3

|

132

|

2.8

|

Installation Diagram

Performance Data(2)

Performance Data(2)

|

Model

|

A

|

B

|

C

|

E

|

F

|

L

|

I

|

M

|

N

|

O

|

H

|

J

|

b

|

K

|

P

|

Q

|

n-φd

|

|

DG6-25×3

|

1175

|

885

|

600

|

145

|

192

|

250

|

180

|

265

|

135

|

210

|

230

|

440

|

170

|

413

|

390

|

390

|

4-φ24

|

|

DG6-25×4

|

1225

|

985

|

650

|

195

|

142

|

250

|

230

|

265

|

135

|

210

|

230

|

400

|

170

|

413

|

390

|

390

|

4-φ24

|

|

DG6-25×5

|

1275

|

985

|

650

|

195

|

192

|

250

|

280

|

265

|

135

|

210

|

230

|

400

|

170

|

413

|

390

|

390

|

4-φ24

|

|

DG6-25×6

|

1450

|

1205

|

785

|

245

|

141

|

250

|

330

|

265

|

165

|

255

|

240

|

410

|

170

|

465

|

435

|

435

|

4-φ24

|

|

DG6-25×7

|

1500

|

1205

|

785

|

245

|

191

|

250

|

380

|

265

|

165

|

255

|

240

|

410

|

170

|

465

|

435

|

435

|

4-φ24

|

|

DG6-25×8

|

1550

|

1305

|

835

|

295

|

141

|

250

|

430

|

265

|

165

|

255

|

240

|

410

|

170

|

465

|

435

|

435

|

4-φ24

|

|

DG6-25×9

|

1600

|

1305

|

835

|

295

|

191

|

250

|

480

|

265

|

165

|

255

|

240

|

410

|

170

|

465

|

435

|

435

|

4-φ24

|

|

DG6-25×10

|

1695

|

1500

|

935

|

370

|

91

|

250

|

530

|

265

|

165

|

255

|

240

|

410

|

170

|

465

|

435

|

435

|

4-φ24

|

|

DG6-25×11

|

1745

|

1500

|

935

|

370

|

141

|

250

|

580

|

265

|

165

|

255

|

240

|

410

|

170

|

465

|

435

|

435

|

4-φ24

|

|

DG6-25×12

|

1795

|

1500

|

935

|

370

|

191

|

250

|

630

|

265

|

165

|

255

|

240

|

410

|

170

|

465

|

435

|

435

|

4-φ24

|

|

Model

|

A

|

B

|

C

|

E

|

F

|

L

|

I

|

M

|

N

|

O

|

H

|

J

|

b

|

K

|

P

|

Q

|

n-φd

|

|

DG12-25×3

|

1175

|

874

|

600

|

140

|

180

|

250

|

180

|

265

|

135

|

210

|

230

|

400

|

170

|

413

|

395

|

295

|

4-φ25

|

|

DG12-25×4

|

1350

|

1040

|

710

|

165

|

183

|

250

|

230

|

265

|

165

|

255

|

240

|

410

|

170

|

465

|

430

|

430

|

4-φ25

|

|

DG12-25×5

|

1400

|

1090

|

730

|

190

|

183

|

250

|

280

|

265

|

165

|

255

|

240

|

410

|

170

|

465

|

430

|

430

|

4-φ25

|

|

DG12-25×6

|

1450

|

1140

|

740

|

232

|

183

|

250

|

330

|

265

|

165

|

255

|

240

|

410

|

170

|

465

|

430

|

430

|

4-φ25

|

|

DG12-25×7

|

1500

|

1190

|

780

|

242

|

183

|

250

|

380

|

265

|

165

|

255

|

240

|

410

|

170

|

465

|

430

|

430

|

4-φ25

|

|

DG12-25×8

|

1595

|

1284

|

830

|

266

|

183

|

250

|

430

|

265

|

165

|

255

|

240

|

410

|

170

|

465

|

430

|

430

|

4-φ25

|

|

DG12-25×9

|

1645

|

1334

|

850

|

294

|

183

|

250

|

840

|

265

|

165

|

255

|

240

|

410

|

170

|

465

|

430

|

430

|

4-φ25

|

|

DG12-25×10

|

1720

|

1397

|

870

|

327

|

172

|

250

|

530

|

265

|

180

|

285

|

260

|

430

|

170

|

510

|

400

|

460

|

4-φ25

|

|

DG12-25×11

|

1770

|

1447

|

900

|

347

|

172

|

250

|

580

|

265

|

180

|

285

|

260

|

430

|

170

|

510

|

400

|

460

|

4-φ25

|

|

DG12-25×12

|

1925

|

1571

|

980

|

371

|

176

|

250

|

633

|

265

|

200

|

310

|

260

|

450

|

170

|

555

|

400

|

500

|

4-φ25

|

|

Model

|

A

|

B

|

C

|

E

|

F

|

L

|

I

|

M

|

N

|

O

|

H

|

J

|

b

|

K

|

P

|

Q

|

n-φd

|

|

DG25-30×3

|

1450

|

1110

|

760

|

185

|

227

|

285

|

230

|

330

|

165

|

255

|

250

|

460

|

210

|

475

|

460

|

460

|

4-φ30

|

|

DG25-30×4

|

1560

|

1219

|

850

|

204

|

228

|

285

|

295

|

330

|

165

|

255

|

250

|

460

|

210

|

475

|

460

|

460

|

4-φ30

|

|

DG25-30×5

|

1650

|

1297

|

880

|

237

|

228

|

285

|

360

|

330

|

180

|

285

|

260

|

470

|

210

|

510

|

460

|

460

|

4-φ30

|

|

DG25-30×6

|

1825

|

1432

|

970

|

262

|

225

|

285

|

425

|

330

|

200

|

310

|

280

|

490

|

210

|

555

|

460

|

505

|

4-φ30

|

|

DG25-30×7

|

1885

|

1497

|

1000

|

297

|

225

|

285

|

490

|

330

|

200

|

310

|

280

|

490

|

210

|

555

|

460

|

505

|

4-φ30

|

|

DG25-30×8

|

1950

|

1562

|

1030

|

332

|

225

|

285

|

555

|

330

|

200

|

310

|

280

|

490

|

210

|

555

|

460

|

505

|

4-φ30

|

|

DG25-30×9

|

2015

|

1627

|

1080

|

347

|

225

|

285

|

620

|

330

|

200

|

310

|

280

|

490

|

210

|

555

|

460

|

505

|

4-φ30

|

|

DG25-30×10

|

2150

|

1728

|

1120

|

398

|

222

|

285

|

685

|

330

|

225

|

345

|

305

|

515

|

210

|

610

|

540

|

460

|

4-φ30

|

|

Model

|

A

|

B

|

C

|

E

|

F

|

L

|

I

|

M

|

N

|

O

|

H

|

J

|

b

|

K

|

P

|

Q

|

n-φd

|

|

DG46-30×3

|

1520

|

1167

|

845

|

130

|

228

|

285

|

230

|

330

|

180

|

285

|

260

|

470

|

210

|

510

|

460

|

460

|

4-φ30

|

|

DG46-30×4

|

1690

|

1302

|

850

|

242

|

225

|

285

|

295

|

330

|

200

|

310

|

280

|

490

|

210

|

555

|

460

|

505

|

4-φ30

|

|

DG46-30×5

|

1755

|

1367

|

910

|

247

|

225

|

285

|

360

|

330

|

200

|

310

|

280

|

490

|

210

|

555

|

460

|

505

|

4-φ30

|

|

DG46-30×6

|

1820

|

1432

|

935

|

287

|

225

|

285

|

425

|

330

|

200

|

310

|

280

|

490

|

210

|

555

|

460

|

505

|

4-φ30

|

|

DG46-30×7

|

1925

|

1532

|

1010

|

302

|

223

|

285

|

490

|

330

|

225

|

345

|

305

|

515

|

210

|

610

|

460

|

545

|

4-φ30

|

|

DG46-30×8

|

2105

|

1694

|

1110

|

349

|

221

|

285

|

555

|

330

|

250

|

385

|

330

|

540

|

210

|

655

|

460

|

594

|

4-φ30

|

|

DG46-30×9

|

2170

|

1759

|

1140

|

384

|

221

|

285

|

620

|

330

|

250

|

385

|

330

|

540

|

210

|

655

|

460

|

594

|

4-φ30

|

|

DG46-30×10

|

2305

|

1897

|

1245

|

402

|

219

|

285

|

685

|

330

|

280

|

410

|

360

|

570

|

210

|

720

|

460

|

650

|

4-φ30

|

|

Model

|

A

|

B

|

C

|

E

|

F

|

L

|

I

|

M

|

N

|

O

|

H

|

J

|

b

|

K

|

P

|

Q

|

n-φd

|

|

DG46-50×3

|

1717

|

1317

|

875

|

215

|

246

|

339

|

245

|

353

|

200

|

310

|

360

|

630

|

300

|

635

|

500

|

500

|

4-φ24

|

|

DG46-50×4

|

1817

|

1415

|

925

|

293

|

246

|

339

|

305

|

353

|

225

|

345

|

420

|

690

|

300

|

725

|

500

|

500

|

4-φ24

|

|

DG46-50×5

|

1992

|

1571

|

1020

|

341

|

240

|

339

|

365

|

353

|

250

|

385

|

420

|

690

|

300

|

745

|

500

|

600

|

4-φ24

|

|

DG46-50×6

|

2122

|

1758

|

1130

|

321

|

180

|

339

|

425

|

353

|

280

|

410

|

420

|

690

|

300

|

780

|

500

|

650

|

6-φ24

|

|

DG46-50×7

|

2182

|

1758

|

1130

|

321

|

240

|

339

|

485

|

353

|

280

|

410

|

420

|

690

|

300

|

780

|

500

|

650

|

6-φ24

|

|

DG46-50×8

|

2292

|

1869

|

1180

|

331

|

240

|

339

|

545

|

353

|

280

|

410

|

420

|

690

|

300

|

780

|

500

|

650

|

6-φ24

|

|

DG46-50×9

|

2473

|

2046

|

1330

|

360

|

166

|

339

|

605

|

353

|

323

|

550

|

515

|

785

|

300

|

970

|

500

|

750

|

6-φ24

|

|

DG46-50×10

|

2533

|

2046

|

1330

|

360

|

226

|

339

|

665

|

353

|

323

|

550

|

515

|

785

|

300

|

970

|

500

|

750

|

6-φ24

|

|

DG46-50×11

|

2641

|

2222

|

1480

|

370

|

166

|

339

|

725

|

353

|

323

|

550

|

515

|

785

|

300

|

970

|

500

|

750

|

6-φ24

|

|

DG46-50×12

|

2701

|

2222

|

1480

|

370

|

226

|

339

|

785

|

353

|

323

|

550

|

515

|

785

|

300

|

970

|

500

|

750

|

6-φ24

|

Outline Drawing(2)

Performance Data(3)

|

Dimensions

|

Suction Flange

|

Discharge Flange

|

||||||

|

Model

|

Dg

|

Do

|

D

|

n-do

|

Dg

|

Do

|

D

|

n-do

|

|

D6-25 / DG6-25

|

40

|

100

|

130

|

4-φ13.5

|

40

|

110

|

150

|

4-φ17.5

|

|

D12-25 / DG12-25

|

50

|

110

|

140

|

4-φ13.5

|

40

|

110

|

150

|

4-φ17.5

|

|

D25-30 / DG25-30

|

65

|

130

|

160

|

4-φ17.5

|

65

|

145

|

185

|

8-φ17.5

|

|

D46-30 / DG46-30

|

80

|

150

|

190

|

4-φ17.5

|

65

|

145

|

185

|

8-φ17.5

|

|

D46-50 / DG46-50

|

80

|

150 / 170

|

190 / 215

|

4-φ17.5 / 8-φ22

|

80

|

170

|

215

|

8-φ22

|

Operating Manual

1) Assembly Sequence:

(1) Install sealing rings onto the suction section and guide vane plate.

(2) Install the diffuser sleeve onto the middle section, then install the diffuser plate on all middle sections.

(3) Install shaft sleeve A and the shaft through the suction section, push in the impeller, place a paper gasket on the middle section, install the middle section, then push in the second impeller. Repeat until all impellers and middle sections are installed.

(4) Install the balance ring, balance sleeve, and discharge diffuser onto the discharge section.

(5) Assemble the discharge section onto the middle section, then tighten the suction, middle, and discharge sections using tie bolts.

(6) Install the balance disc and shaft sleeve B (50D8 pump has no such part).

(7) Install gasket and stuffing box on the tail cover, then install packing, packing ring, and packing gland into the stuffing chambers of suction and tail cover.

(8) Install bearing housings on both suction and tail covers and tighten with bolts.

(9) Install bearing locating sleeve, ball bearings, and secure with nuts.

(10) Fill bearings with grease, install gasket on bearing cover, and tighten the bearing cover.

(11) Install coupling components, vent valve, and pipe plugs.

Disassembly is done in reverse order.

2) Installation:

1. Preparations:

– Inspect pump and motor.

– Prepare tools and lifting equipment.

– Check foundation.

2. Installation Steps:

– Move the unit to the site. If the unit has a base, and the motor is pre-installed, no need to disassemble.

– Position the base on the foundation using wedges. Raise 20–40 mm for grouting.

– Level the base, tighten the anchor bolts, and then grout.

– After 3–4 days, re-check the level.

– Clean the mounting surfaces of the base, pump feet, motor feet, then place the pump and motor.

– Align the pump shaft horizontally and tighten lightly. Install the motor; adjust with shims if needed.

– Use a straightedge on the coupling to check alignment. Correct until the coupling plane deviation is ≤0.3 mm and center deviation ≤0.1 mm.

3) Startup & Shutdown:

– Clean oil from shaft and other lubricated parts.

– Clean bearings and oil chamber with gasoline, then wipe dry.

– Fill bearings with grease.

– Test-run the motor direction.

– Fill pump with water or prime pump.

– Close discharge valve and pressure gauge cock.

– Start the motor and open the pressure gauge cock.

– When the pump runs normally, gradually open the discharge valve.

– Shutdown: slowly close the discharge valve, close the vacuum gauge cock, stop the motor, and finally close the pressure gauge cock.

– For long-term shutdown, drain the pump, clean, oil components, and store properly.

4) Operation:

– Bearing temperature must not exceed ambient temperature by more than 35°C; max 75°C.

– Normal packing leakage ≤ 15 ml/min; adjust as necessary.

– Regularly inspect the coupling and monitor motor bearing temperature rise.

– Stop pump immediately if abnormal noise or vibration occurs.

OEM & Custom

We provide OEM/ODM manufacturing with options for stainless steel, cast iron, or special alloys. Customizations include voltage (220V/415V/460V), explosion-proof motors, base-mounted assemblies, and control panels. Each unit is tested for hydraulic performance, vibration, and noise compliance under ISO and CE export standards.

FAQs

- Q: What’s the main application of the D/DG multistage pump?

A: It’s mainly used for industrial water supply, boiler feed, pressure boosting, and clean water circulation. - Q: What temperature range can it handle?

A: D type ≤80°C; DG type ≤105°C, suitable for high-temperature water systems. - Q: What materials are available?

A: Standard cast iron, with optional stainless steel or alloy materials for corrosive liquids. - Q: Can it operate under high pressure?

A: Yes, it can achieve heads up to 680 meters depending on the model and stage count. - Q: How often should maintenance be performed?

A: Inspect seals and bearings every 500 hours; perform a full overhaul every 12 months. - Q: Do you offer customized motor and control systems?

A: Yes, we support OEM motor configurations, VFD control panels, and export packaging. - Q: Which markets use this pump?

A: Widely exported to Southeast Asia, the Middle East, and South America for industrial, municipal, and mining water systems.