Product Overview

The DL/DLR vertical multistage low-speed clean-water pump (n = 1450 r/min) is designed to meet practical water-supply requirements in high-rise buildings and complies with GB 6245-2006 — Performance Requirements and Test Methods for Fire Pumps.

It is used for conveying clean water or water-like liquids with similar physical and chemical properties, free of hard particles.

Performance range: Flow 5–360 m³/h, head 22–300 m, power 1.5–220 kW, nozzle diameter φ40–φ200 mm.

A single pump can be configured with 1 to 5 discharge ports.

Model Designation

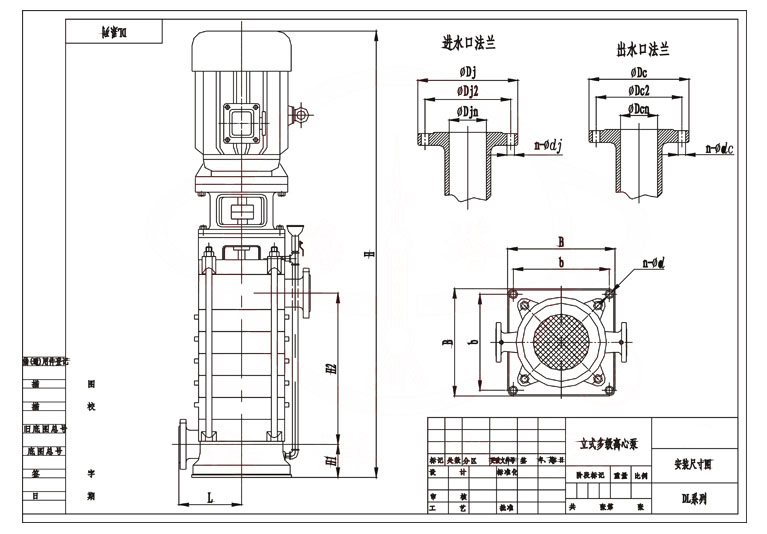

Installation & Dimensions

Outline Drawing

Performance Data

|

No.

|

Name

|

Material / Model

|

No.

|

Name

|

Material / Model

|

|

1

|

Motor

|

Y Series (V5) 4-Pole

|

12

|

Discharge Section

|

HT200

|

|

2

|

Coupling

|

HT200

|

13

|

Balance Sleeve

|

HT200

|

|

3

|

Elastic Block

|

Rubber

|

14

|

Balance Drum

|

HT200

|

|

4

|

Bearing Cover

|

HT200

|

15

|

Final Stage Diffuser

|

HT200

|

|

5

|

Bearing Lock Nut

|

45

|

16

|

Intermediate Section

|

HT200

|

|

6

|

Bearing Housing

|

HT200

|

17

|

Diffuser

|

HT200

|

|

7

|

Bearing

|

Series 180

|

18

|

Impeller

|

HT200

|

|

8

|

Water Deflector Sleeve

|

45

|

19

|

Suction Section

|

HT200

|

|

9

|

Asbestos Gland

|

HT200

|

20

|

Lower Shaft Sleeve

|

45

|

|

10

|

Asbestos Packing

|

Asbestos

|

21

|

Lower Bearing

|

Copper Alloy

|

|

11

|

Stuffing Box Body

|

HT200

|

22

|

Shaft

|

45, 2Cr13

|

| Note: 1. This pump model can be customized as a hot-water type upon request. 2. The asbestos packing can be replaced with a mechanical seal. 3. Please specify these requirements when placing an order; pricing will be discussed separately. |

|||||

Performance Parameters

|

Model

|

Stages

|

Speed

|

Efficiency

|

NPSH Required

|

Flow Rate

|

Head

|

Power

|

Weight

|

|

r/min

|

%

|

m

|

m³/h

|

m

|

kW

|

Kg

|

||

|

40DL6.2-11.2*2

|

2

|

1450

|

40

|

3.19

|

6.2

|

23.6

|

1.5

|

152

|

|

40DL6.2-11.2*3

|

3

|

1450

|

40

|

3.19

|

6.2

|

35.4

|

2.2

|

169

|

|

40DL6.2-11.2*4

|

4

|

1450

|

40

|

3.19

|

6.2

|

47.2

|

3

|

186

|

|

40DL6.2-11.2*5

|

5

|

1450

|

40

|

3.19

|

6.2

|

59

|

4

|

203

|

|

40DL6.2-11.2*6

|

6

|

1450

|

40

|

3.19

|

6.2

|

70.8

|

4

|

220

|

|

40DL6.2-11.2*7

|

7

|

1450

|

40

|

3.19

|

6.2

|

82.6

|

5.5

|

237

|

|

40DL6.2-11.2*8

|

8

|

1450

|

40

|

3.19

|

6.2

|

94.4

|

5.5

|

254

|

|

40DL6.2-11.2*9

|

9

|

1450

|

40

|

3.19

|

6.2

|

106.2

|

7.5

|

271

|

|

40DL6.2-11.2*10

|

10

|

1450

|

40

|

3.19

|

6.2

|

118

|

7.5

|

/

|

|

40DL6.2-11.2*11

|

11

|

1450

|

40

|

3.19

|

6.2

|

129.8

|

7.5

|

/

|

|

40DL6.2-11.2*12

|

12

|

1450

|

40

|

3.19

|

6.2

|

141.6

|

11

|

/

|

|

Model

|

Stages

|

Speed

|

Efficiency

|

NPSH Required

|

Flow Rate

|

Head

|

Power

|

Weight

|

|

r/min

|

%

|

m

|

m³/h

|

m

|

kW

|

Kg

|

||

|

50DL12.6-12.2*2

|

2

|

1450

|

54

|

2.66

|

12.6

|

24.4

|

3

|

15.3

|

|

50DL12.6-12.2*3

|

3

|

1450

|

54

|

2.66

|

12.6

|

36.6

|

3

|

18

|

|

50DL12.6-12.2*4

|

4

|

1450

|

54

|

2.66

|

12.6

|

48.8

|

4

|

23.1

|

|

50DL12.6-12.2*5

|

5

|

1450

|

54

|

2.66

|

12.6

|

61

|

5.5

|

33

|

|

50DL12.6-12.2*6

|

6

|

1450

|

54

|

2.66

|

12.6

|

73.2

|

5.5

|

24

|

|

50DL12.6-12.2*7

|

7

|

1450

|

54

|

2.66

|

12.6

|

85.4

|

7.5

|

15

|

|

50DL12.6-12.2*8

|

8

|

1450

|

54

|

2.66

|

12.6

|

97.6

|

7.5

|

18

|

|

50DL12.6-12.2*9

|

9

|

1450

|

54

|

2.66

|

12.6

|

109.8

|

11

|

22

|

|

50DL12.6-12.2*10

|

10

|

1450

|

54

|

2.66

|

12.6

|

122

|

11

|

/

|

|

Model

|

Stages

|

Speed

|

Efficiency

|

NPSH Required

|

Flow Rate

|

Head

|

Power

|

Weight

|

|

r/min

|

%

|

m

|

m³/h

|

m

|

kW

|

Kg

|

||

|

65DL30-16*2

|

2

|

1450

|

62

|

2.82

|

30

|

32

|

5.5

|

349

|

|

65DL30-16*3

|

3

|

1450

|

62

|

2.82

|

30

|

48

|

7.5

|

390

|

|

65DL30-16*4

|

4

|

1450

|

62

|

2.82

|

30

|

64

|

11

|

460

|

|

65DL30-16*5

|

5

|

1450

|

62

|

2.82

|

30

|

80

|

15

|

509

|

|

65DL30-16*6

|

6

|

1450

|

62

|

2.82

|

30

|

96

|

15

|

537

|

|

65DL30-16*7

|

7

|

1450

|

62

|

2.82

|

30

|

112

|

18.5

|

603

|

|

65DL30-16*8

|

8

|

1450

|

62

|

2.82

|

30

|

128

|

22

|

639

|

|

65DL30-16*9

|

9

|

1450

|

62

|

2.82

|

30

|

144

|

22

|

667

|

|

65DL30-16*10

|

10

|

1450

|

62

|

2.82

|

30

|

160

|

30

|

720

|

|

Model

|

Stages

|

Speed

|

Efficiency

|

NPSH Required

|

Flow Rate

|

Head

|

Power

|

Weight

|

|

r/min

|

%

|

m

|

m³/h

|

m

|

kW

|

Kg

|

||

|

80DL50-20*2

|

2

|

1450

|

70

|

2.5

|

50

|

40

|

11

|

461

|

|

80DL50-20*3

|

3

|

1450

|

70

|

2.5

|

50

|

60

|

15

|

522

|

|

80DL50-20*4

|

4

|

1450

|

70

|

2.5

|

50

|

80

|

22

|

608

|

|

80DL50-20*5

|

5

|

1450

|

70

|

2.5

|

50

|

100

|

30

|

728

|

|

80DL50-20*6

|

6

|

1450

|

70

|

2.5

|

50

|

120

|

30

|

768

|

|

80DL50-20*7

|

7

|

1450

|

70

|

2.5

|

50

|

140

|

37

|

822

|

|

80DL50-20*8

|

8

|

1450

|

70

|

2.5

|

50

|

160

|

45

|

898

|

|

80DL50-20*9

|

9

|

1450

|

70

|

2.5

|

50

|

180

|

45

|

938

|

|

80DL50-20*10

|

10

|

1450

|

70

|

2.5

|

50

|

200

|

55

|

/

|

|

Model

|

Stages

|

Speed

|

Efficiency

|

NPSH Required

|

Flow Rate

|

Head

|

Power

|

Weight

|

|

r/min

|

%

|

m

|

m³/h

|

m

|

kW

|

Kg

|

||

|

100DL72-20*2

|

2

|

1450

|

72

|

2.8

|

72

|

40

|

15

|

521

|

|

100DL72-20*3

|

3

|

1450

|

72

|

2.8

|

72

|

60

|

18.5

|

599

|

|

100DL72-20*4

|

4

|

1450

|

72

|

2.8

|

72

|

80

|

30

|

727

|

|

100DL72-20*5

|

5

|

1450

|

72

|

2.8

|

72

|

100

|

37

|

781

|

|

100DL72-20*6

|

6

|

1450

|

72

|

2.8

|

72

|

120

|

37

|

821

|

|

100DL72-20*7

|

7

|

1450

|

72

|

2.8

|

72

|

140

|

45

|

897

|

|

100DL72-20*8

|

8

|

1450

|

72

|

2.8

|

72

|

160

|

55

|

1044

|

|

100DL72-20*9

|

9

|

1450

|

72

|

2.8

|

72

|

180

|

55

|

1084

|

|

100DL72-20*10

|

10

|

1450

|

72

|

2.8

|

72

|

200

|

75

|

/

|

|

Model

|

Stages

|

Speed

|

Efficiency

|

NPSH Required

|

Flow Rate

|

Head

|

Power

|

Weight

|

|

r/min

|

%

|

m

|

m³/h

|

m

|

kW

|

Kg

|

||

|

100DL100-20*2

|

2

|

1450

|

72

|

3.5

|

100

|

40

|

18.5

|

554

|

|

100DL100-20*3

|

3

|

1450

|

72

|

3.5

|

100

|

60

|

30

|

687

|

|

100DL100-20*4

|

4

|

1450

|

72

|

3.5

|

100

|

80

|

37

|

746

|

|

100DL100-20*5

|

5

|

1450

|

72

|

3.5

|

100

|

100

|

45

|

827

|

|

100DL100-20*6

|

6

|

1450

|

72

|

3.5

|

100

|

120

|

55

|

979

|

|

100DL100-20*7

|

7

|

1450

|

72

|

3.5

|

100

|

140

|

75

|

1159

|

|

100DL100-20*8

|

8

|

1450

|

72

|

3.5

|

100

|

160

|

75

|

1204

|

|

100DL100-20*9

|

9

|

1450

|

72

|

3.5

|

100

|

180

|

90

|

1354

|

|

100DL100-20*10

|

10

|

1450

|

72

|

3.5

|

100

|

200

|

90

|

/

|

|

Model

|

Stages

|

Speed

|

Efficiency

|

NPSH Required

|

Flow Rate

|

Head

|

Power

|

Weight

|

|

r/min

|

%

|

m

|

m³/h

|

m

|

kW

|

Kg

|

||

|

150DL150-20*2

|

2

|

1450

|

80

|

2.8

|

150

|

40

|

30

|

569

|

|

150DL150-20*3

|

3

|

1450

|

80

|

2.8

|

150

|

60

|

37

|

707

|

|

150DL150-20*4

|

4

|

1450

|

80

|

2.8

|

150

|

80

|

45

|

771

|

|

150DL150-20*5

|

5

|

1450

|

80

|

2.8

|

150

|

100

|

55

|

857

|

|

150DL150-20*6

|

6

|

1450

|

80

|

2.8

|

150

|

120

|

75

|

1060

|

|

150DL150-20*7

|

7

|

1450

|

80

|

2.8

|

150

|

140

|

75

|

1245

|

|

150DL150-20*8

|

8

|

1450

|

80

|

2.8

|

150

|

160

|

90

|

1295

|

|

Model

|

Stages

|

Speed

|

Efficiency

|

NPSH Required

|

Flow Rate

|

Head

|

Power

|

Weight

|

|

r/min

|

%

|

m

|

m³/h

|

m

|

kW

|

Kg

|

||

|

150DL160-25*2

|

2

|

1450

|

76

|

3.5

|

160

|

50

|

37

|

873

|

|

150DL160-25*3

|

3

|

1450

|

76

|

3.5

|

160

|

75

|

55

|

1086

|

|

150DL160-25*4

|

4

|

1450

|

76

|

3.5

|

160

|

100

|

75

|

1291

|

|

150DL160-25*5

|

5

|

1450

|

76

|

3.5

|

160

|

125

|

90

|

1466

|

|

150DL160-25*6

|

6

|

1450

|

76

|

3.5

|

160

|

150

|

110

|

1633

|

|

150DL160-25*7

|

7

|

1450

|

76

|

3.5

|

160

|

175

|

132

|

1803

|

|

150DL160-25*8

|

8

|

1450

|

76

|

3.5

|

160

|

200

|

132

|

1873

|

|

150DL160-25*9

|

9

|

1450

|

76

|

3.5

|

160

|

225

|

160

|

2003

|

|

Model

|

Stages

|

Speed

|

Efficiency

|

NPSH Required

|

Flow Rate

|

Head

|

Power

|

Weight

|

|

r/min

|

%

|

m

|

m³/h

|

m

|

kW

|

Kg

|

||

|

200DL300-20*2

|

2

|

1450

|

79

|

5

|

300

|

40

|

55

|

983

|

|

200DL300-20*3

|

3

|

1450

|

79

|

5

|

300

|

60

|

75

|

1196

|

|

200DL300-20*4

|

4

|

1450

|

79

|

5

|

300

|

80

|

110

|

1845

|

|

200DL300-20*5

|

5

|

1450

|

79

|

5

|

300

|

100

|

132

|

1975

|

|

200DL300-20*6

|

6

|

1450

|

79

|

5

|

300

|

120

|

160

|

2120

|

|

200DL288-30*2

|

2

|

1450

|

77.9

|

3.7

|

288

|

60

|

75

|

/

|

|

200DL288-30*3

|

3

|

1450

|

77.9

|

3.7

|

288

|

90

|

110

|

/

|

|

200DL288-30*4

|

4

|

1450

|

77.9

|

3.7

|

288

|

120

|

132

|

/

|

|

200DL288-30*5

|

5

|

1450

|

77.9

|

3.7

|

288

|

150

|

160

|

/

|

|

200DL288-30*6

|

6

|

1450

|

77.9

|

3.7

|

288

|

180

|

200

|

/

|

Installation Diagram

Performance Data (2)

|

Model

|

Stages

|

L

|

H

|

H1

|

H2

|

B

|

b

|

n-φd

|

Inlet Flange

|

Outlet Flange

|

||||||

|

Dj

|

Djn

|

Dj2

|

n-dj

|

Dc

|

Dcn

|

Dc2

|

n-φdc

|

|||||||||

|

40DL6.2-11.2

|

2

|

225

|

938

|

112

|

170

|

350

|

300

|

4-φ18

|

150

|

40

|

110

|

4-φ18

|

150

|

40

|

110

|

4-φ18

|

|

40DL6.2-11.2

|

3

|

225

|

1043

|

112

|

230

|

350

|

300

|

4-φ18

|

150

|

40

|

110

|

4-φ18

|

150

|

40

|

110

|

4-φ18

|

|

40DL6.2-11.2

|

4

|

225

|

1103

|

112

|

290

|

350

|

300

|

4-φ18

|

150

|

40

|

110

|

4-φ18

|

150

|

40

|

110

|

4-φ18

|

|

40DL6.2-11.2

|

5

|

225

|

1183

|

112

|

350

|

350

|

300

|

4-φ18

|

150

|

40

|

110

|

4-φ18

|

150

|

40

|

110

|

4-φ18

|

|

40DL6.2-11.2

|

6

|

225

|

1243

|

112

|

410

|

350

|

300

|

4-φ18

|

150

|

40

|

110

|

4-φ18

|

150

|

40

|

110

|

4-φ18

|

|

40DL6.2-11.2

|

7

|

225

|

1378

|

112

|

470

|

350

|

300

|

4-φ18

|

150

|

40

|

110

|

4-φ18

|

150

|

40

|

110

|

4-φ18

|

|

40DL6.2-11.2

|

8

|

225

|

1438

|

112

|

530

|

350

|

300

|

4-φ18

|

150

|

40

|

110

|

4-φ18

|

150

|

40

|

110

|

4-φ18

|

|

40DL6.2-11.2

|

9

|

225

|

1538

|

112

|

590

|

350

|

300

|

4-φ18

|

150

|

40

|

110

|

4-φ18

|

150

|

40

|

110

|

4-φ18

|

|

40DL6.2-11.2

|

10

|

225

|

1598

|

112

|

650

|

350

|

300

|

4-φ18

|

150

|

40

|

110

|

4-φ18

|

150

|

40

|

110

|

4-φ18

|

|

40DL6.2-11.2

|

11

|

225

|

1658

|

112

|

710

|

350

|

300

|

4-φ18

|

150

|

40

|

110

|

4-φ18

|

150

|

40

|

110

|

4-φ18

|

|

40DL6.2-11.2

|

12

|

225

|

1803

|

112

|

770

|

350

|

300

|

4-φ18

|

150

|

40

|

110

|

4-φ18

|

150

|

40

|

110

|

4-φ18

|

|

Model

|

Stages

|

L

|

H

|

H1

|

H2

|

B

|

b

|

n-φd

|

Inlet Flange

|

Outlet Flange

|

||||||

|

Dj

|

Djn

|

Dj2

|

n-dj

|

Dc

|

Dcn

|

Dc2

|

n-φdc

|

|||||||||

|

50DL12.6-12.2

|

2

|

220

|

1084

|

104

|

189

|

360

|

305

|

4-φ18

|

165

|

50

|

125

|

4-φ18

|

150

|

40

|

110

|

4-φ18

|

|

50DL12.6-12.2

|

3

|

220

|

1152

|

104

|

257

|

360

|

305

|

4-φ18

|

165

|

50

|

125

|

4-φ18

|

150

|

40

|

110

|

4-φ18

|

|

50DL12.6-12.2

|

4

|

220

|

1240

|

104

|

325

|

360

|

305

|

4-φ18

|

165

|

50

|

125

|

4-φ18

|

150

|

40

|

110

|

4-φ18

|

|

50DL12.6-12.2

|

5

|

220

|

1383

|

104

|

393

|

360

|

305

|

4-φ18

|

165

|

50

|

125

|

4-φ18

|

150

|

40

|

110

|

4-φ18

|

|

50DL12.6-12.2

|

6

|

220

|

1451

|

104

|

461

|

360

|

305

|

4-φ18

|

165

|

50

|

125

|

4-φ18

|

150

|

40

|

110

|

4-φ18

|

|

50DL12.6-12.2

|

7

|

220

|

1559

|

104

|

529

|

360

|

305

|

4-φ18

|

165

|

50

|

125

|

4-φ18

|

150

|

40

|

110

|

4-φ18

|

|

50DL12.6-12.2

|

8

|

220

|

1629

|

104

|

597

|

360

|

305

|

4-φ18

|

165

|

50

|

125

|

4-φ18

|

150

|

40

|

110

|

4-φ18

|

|

50DL12.6-12.2

|

9

|

220

|

1780

|

104

|

665

|

360

|

305

|

4-φ18

|

165

|

50

|

125

|

4-φ18

|

150

|

40

|

110

|

4-φ18

|

|

50DL12.6-12.2

|

10

|

220

|

1848

|

104

|

733

|

360

|

305

|

4-φ18

|

165

|

50

|

125

|

4-φ18

|

150

|

40

|

110

|

4-φ18

|

|

Model

|

Stages

|

L

|

H

|

H1

|

H2

|

B

|

b

|

n-φd

|

Inlet Flange

|

Outlet Flange

|

||||||

|

Dj

|

Djn

|

Dj2

|

n-dj

|

Dc

|

Dcn

|

Dc2

|

n-φdc

|

|||||||||

|

65DL30-16

|

2

|

260

|

1306

|

170

|

199

|

430

|

370

|

4-φ24

|

185

|

65

|

145

|

4-φ18

|

165

|

50

|

125

|

4-φ18

|

|

65DL30-16

|

3

|

260

|

1426

|

170

|

279

|

430

|

370

|

4-φ24

|

185

|

65

|

145

|

4-φ18

|

165

|

50

|

125

|

4-φ18

|

|

65DL30-16

|

4

|

260

|

1591

|

170

|

359

|

430

|

370

|

4-φ24

|

185

|

65

|

145

|

4-φ18

|

165

|

50

|

125

|

4-φ18

|

|

65DL30-16

|

5

|

260

|

1716

|

170

|

439

|

430

|

370

|

4-φ24

|

185

|

65

|

145

|

4-φ18

|

165

|

50

|

125

|

4-φ18

|

|

65DL30-16

|

6

|

260

|

1796

|

170

|

519

|

430

|

370

|

4-φ24

|

185

|

65

|

145

|

4-φ18

|

165

|

50

|

125

|

4-φ18

|

|

65DL30-16

|

7

|

260

|

1901

|

170

|

599

|

430

|

370

|

4-φ24

|

185

|

65

|

145

|

4-φ18

|

165

|

50

|

125

|

4-φ18

|

|

65DL30-16

|

8

|

260

|

2021

|

170

|

679

|

430

|

370

|

4-φ24

|

185

|

65

|

145

|

4-φ18

|

165

|

50

|

125

|

4-φ18

|

|

65DL30-16

|

9

|

260

|

2101

|

170

|

759

|

430

|

370

|

4-φ24

|

185

|

65

|

145

|

4-φ18

|

165

|

50

|

125

|

4-φ18

|

|

65DL30-16

|

10

|

260

|

2246

|

170

|

839

|

430

|

370

|

4-φ24

|

185

|

65

|

145

|

4-φ18

|

165

|

50

|

125

|

4-φ18

|

|

Model

|

Stages

|

L

|

H

|

H1

|

H2

|

B

|

b

|

n-φd

|

Inlet Flange

|

Outlet Flange

|

||||||

|

Dj

|

Djn

|

Dj2

|

n-dj

|

Dc

|

Dcn

|

Dc2

|

n-φdc

|

|||||||||

|

80DL50-20

|

2

|

280

|

1515

|

120

|

277

|

450

|

400

|

4-φ24

|

200

|

80

|

160

|

8-φ18

|

185

|

65

|

145

|

4-φ18

|

|

80DL50-20

|

3

|

280

|

1649

|

120

|

366

|

450

|

400

|

4-φ24

|

200

|

80

|

160

|

8-φ18

|

185

|

65

|

145

|

4-φ18

|

|

80DL50-20

|

4

|

280

|

1865

|

120

|

455

|

450

|

400

|

4-φ24

|

200

|

80

|

160

|

8-φ18

|

185

|

65

|

145

|

4-φ18

|

|

80DL50-20

|

5

|

280

|

2030

|

120

|

544

|

450

|

400

|

4-φ24

|

200

|

80

|

160

|

8-φ18

|

185

|

65

|

145

|

4-φ18

|

|

80DL50-20

|

6

|

280

|

2120

|

120

|

633

|

450

|

400

|

4-φ24

|

200

|

80

|

160

|

8-φ18

|

185

|

65

|

145

|

4-φ18

|

|

80DL50-20

|

7

|

280

|

2270

|

120

|

722

|

450

|

400

|

4-φ24

|

200

|

80

|

160

|

8-φ18

|

185

|

65

|

145

|

4-φ18

|

|

80DL50-20

|

8

|

280

|

2385

|

120

|

811

|

450

|

400

|

4-φ24

|

200

|

80

|

160

|

8-φ18

|

185

|

65

|

145

|

4-φ18

|

|

80DL50-20

|

9

|

280

|

2475

|

120

|

900

|

450

|

400

|

4-φ24

|

200

|

80

|

160

|

8-φ18

|

185

|

65

|

145

|

4-φ18

|

|

80DL50-20

|

10

|

280

|

2665

|

120

|

989

|

450

|

400

|

4-φ24

|

200

|

80

|

160

|

8-φ18

|

185

|

65

|

145

|

4-φ18

|

|

Model

|

Stages

|

L

|

H

|

H1

|

H2

|

B

|

b

|

n-φd

|

Inlet Flange

|

Outlet Flange

|

||||||

|

Dj

|

Djn

|

Dj2

|

n-dj

|

Dc

|

Dcn

|

Dc2

|

n-φdc

|

|||||||||

|

100DL72-20

|

2

|

285

|

1616

|

180

|

293

|

470

|

405

|

4-φ24

|

220

|

100

|

180

|

8-φ18

|

200

|

80

|

160

|

8-φ18

|

|

100DL72-20

|

3

|

285

|

1784

|

180

|

396

|

470

|

405

|

4-φ24

|

220

|

100

|

180

|

8-φ18

|

200

|

80

|

160

|

8-φ18

|

|

100DL72-20

|

4

|

285

|

1932

|

180

|

499

|

470

|

405

|

4-φ24

|

220

|

100

|

180

|

8-φ18

|

200

|

80

|

160

|

8-φ18

|

|

100DL72-20

|

5

|

285

|

2060

|

180

|

602

|

470

|

405

|

4-φ24

|

220

|

100

|

180

|

8-φ18

|

200

|

80

|

160

|

8-φ18

|

|

100DL72-20

|

6

|

285

|

2248

|

180

|

705

|

470

|

405

|

4-φ24

|

220

|

100

|

180

|

8-φ18

|

200

|

80

|

160

|

8-φ18

|

|

100DL72-20

|

7

|

285

|

2421

|

180

|

808

|

470

|

405

|

4-φ24

|

220

|

100

|

180

|

8-φ18

|

200

|

80

|

160

|

8-φ18

|

|

100DL72-20

|

8

|

285

|

2524

|

180

|

911

|

470

|

405

|

4-φ24

|

220

|

100

|

180

|

8-φ18

|

200

|

80

|

160

|

8-φ18

|

|

100DL72-20

|

9

|

285

|

2677

|

180

|

1014

|

470

|

405

|

4-φ24

|

220

|

100

|

180

|

8-φ18

|

200

|

80

|

160

|

8-φ18

|

|

100DL72-20

|

10

|

285

|

2780

|

180

|

1117

|

470

|

405

|

4-φ24

|

220

|

100

|

180

|

8-φ18

|

200

|

80

|

160

|

8-φ18

|

|

Model

|

Stages

|

L

|

H

|

H1

|

H2

|

B

|

b

|

n-φd

|

Inlet Flange

|

Outlet Flange

|

||||||

|

Dj

|

Djn

|

Dj2

|

n-dj

|

Dc

|

Dcn

|

Dc2

|

n-φdc

|

|||||||||

|

100DL100-20

|

2

|

285

|

1493

|

180

|

293

|

470

|

405

|

4-φ24

|

220

|

100

|

180

|

8-φ18

|

200

|

80

|

160

|

8-φ18

|

|

100DL100-20

|

3

|

285

|

1655

|

180

|

396

|

470

|

405

|

4-φ24

|

220

|

100

|

180

|

8-φ18

|

200

|

80

|

160

|

8-φ18

|

|

100DL100-20

|

4

|

285

|

1777

|

180

|

499

|

470

|

405

|

4-φ24

|

220

|

100

|

180

|

8-φ18

|

200

|

80

|

160

|

8-φ18

|

|

100DL100-20

|

5

|

285

|

1807

|

180

|

602

|

470

|

405

|

4-φ24

|

220

|

100

|

180

|

8-φ18

|

200

|

80

|

160

|

8-φ18

|

|

100DL100-20

|

6

|

285

|

1984

|

180

|

705

|

470

|

405

|

4-φ24

|

220

|

100

|

180

|

8-φ18

|

200

|

80

|

160

|

8-φ18

|

|

100DL100-20

|

7

|

285

|

2111

|

180

|

808

|

470

|

405

|

4-φ24

|

220

|

100

|

180

|

8-φ18

|

200

|

80

|

160

|

8-φ18

|

|

100DL100-20

|

8

|

285

|

2213

|

180

|

911

|

470

|

405

|

4-φ24

|

220

|

100

|

180

|

8-φ18

|

200

|

80

|

160

|

8-φ18

|

|

100DL100-20

|

9

|

285

|

2415

|

180

|

1014

|

470

|

405

|

4-φ24

|

220

|

100

|

180

|

8-φ18

|

200

|

80

|

160

|

8-φ18

|

|

100DL100-20

|

10

|

285

|

2517

|

180

|

1117

|

470

|

405

|

4-φ24

|

220

|

100

|

180

|

8-φ18

|

200

|

80

|

160

|

8-φ18

|

|

Model

|

Stages

|

L

|

H

|

H1

|

H2

|

B

|

b

|

n-φd

|

Inlet Flange

|

Outlet Flange

|

||||||

|

Dj

|

Djn

|

Dj2

|

n-dj

|

Dc

|

Dcn

|

Dc2

|

n-φdc

|

|||||||||

|

150DL150-20

|

2

|

310

|

1680

|

150

|

315

|

470

|

410

|

4-φ24

|

285

|

150

|

240

|

8-φ23

|

245

|

125

|

210

|

8-φ18

|

|

150DL150-20

|

3

|

310

|

1840

|

150

|

430

|

470

|

410

|

4-φ24

|

285

|

150

|

240

|

8-φ23

|

245

|

125

|

210

|

8-φ18

|

|

150DL150-20

|

4

|

310

|

2020

|

150

|

545

|

470

|

410

|

4-φ24

|

285

|

150

|

240

|

8-φ23

|

245

|

125

|

210

|

8-φ18

|

|

150DL150-20

|

5

|

310

|

2260

|

150

|

660

|

470

|

410

|

4-φ24

|

285

|

150

|

240

|

8-φ23

|

245

|

125

|

210

|

8-φ18

|

|

150DL150-20

|

6

|

310

|

2445

|

150

|

775

|

470

|

410

|

4-φ24

|

285

|

150

|

240

|

8-φ23

|

245

|

125

|

210

|

8-φ18

|

|

150DL150-20

|

7

|

310

|

2610

|

150

|

890

|

470

|

410

|

4-φ24

|

285

|

150

|

240

|

8-φ23

|

245

|

125

|

210

|

8-φ18

|

|

150DL150-20

|

8

|

310

|

2725

|

150

|

1005

|

470

|

410

|

4-φ24

|

285

|

150

|

240

|

8-φ23

|

245

|

125

|

210

|

8-φ18

|

|

150DL150-20

|

9

|

310

|

3240

|

150

|

1120

|

470

|

410

|

4-φ24

|

285

|

150

|

240

|

8-φ23

|

245

|

125

|

210

|

8-φ18

|

|

Model

|

Stages

|

L

|

H

|

H1

|

H2

|

B

|

b

|

n-φd

|

Inlet Flange

|

Outlet Flange

|

||||||

|

Dj

|

Djn

|

Dj2

|

n-dj

|

Dc

|

Dcn

|

Dc2

|

n-φdc

|

|||||||||

|

150DL160-25

|

2

|

345

|

1895

|

155

|

372

|

550

|

480

|

4-φ24

|

285

|

150

|

240

|

8-φ23

|

245

|

125

|

210

|

8-φ18

|

|

150DL160-25

|

3

|

345

|

2135

|

155

|

504

|

550

|

480

|

4-φ24

|

285

|

150

|

240

|

8-φ23

|

245

|

125

|

210

|

8-φ18

|

|

150DL160-25

|

4

|

345

|

2335

|

155

|

636

|

550

|

480

|

4-φ24

|

285

|

150

|

240

|

8-φ23

|

245

|

125

|

210

|

8-φ18

|

|

150DL160-25

|

5

|

345

|

2515

|

155

|

768

|

550

|

480

|

4-φ24

|

285

|

150

|

240

|

8-φ23

|

245

|

125

|

210

|

8-φ18

|

|

150DL160-25

|

6

|

345

|

2800

|

155

|

900

|

550

|

480

|

4-φ24

|

285

|

150

|

240

|

8-φ23

|

245

|

125

|

210

|

8-φ18

|

|

150DL160-25

|

7

|

345

|

2975

|

155

|

1032

|

550

|

480

|

4-φ24

|

285

|

150

|

240

|

8-φ23

|

245

|

125

|

210

|

8-φ18

|

|

150DL160-25

|

8

|

345

|

3110

|

155

|

1164

|

550

|

480

|

4-φ24

|

285

|

150

|

240

|

8-φ23

|

245

|

125

|

210

|

8-φ18

|

|

150DL160-25

|

9

|

345

|

3240

|

155

|

1260

|

550

|

480

|

4-φ24

|

285

|

150

|

240

|

8-φ23

|

245

|

125

|

210

|

8-φ18

|

|

Model

|

Stages

|

L

|

H

|

H1

|

H2

|

B

|

b

|

n-φd

|

Inlet Flange

|

Outlet Flange

|

||||||

|

Dj

|

Djn

|

Dj2

|

n-dj

|

Dc

|

Dcn

|

Dc2

|

n-φdc

|

|||||||||

|

200DL300-20

|

2

|

380

|

2010

|

182

|

600

|

600

|

550

|

4-φ24

|

340

|

200

|

295

|

12-φ23

|

285

|

150

|

240

|

8-φ23

|

|

200DL300-20

|

3

|

380

|

2320

|

182

|

760

|

600

|

550

|

4-φ24

|

340

|

200

|

295

|

12-φ23

|

285

|

150

|

240

|

8-φ23

|

|

200DL300-20

|

4

|

380

|

2660

|

182

|

905

|

600

|

550

|

4-φ24

|

340

|

200

|

295

|

12-φ23

|

285

|

150

|

240

|

8-φ23

|

|

200DL300-20

|

5

|

380

|

2860

|

182

|

1050

|

600

|

550

|

4-φ24

|

340

|

200

|

295

|

12-φ23

|

285

|

150

|

240

|

8-φ23

|

|

200DL300-20

|

6

|

380

|

3010

|

182

|

1200

|

600

|

550

|

4-φ24

|

340

|

200

|

295

|

12-φ23

|

285

|

150

|

240

|

8-φ23

|

|

200DL288-30

|

2

|

380

|

2185

|

182

|

600

|

600

|

550

|

4-φ24

|

340

|

200

|

295

|

12-φ23

|

285

|

150

|

240

|

8-φ23

|

|

200DL288-30

|

3

|

380

|

2355

|

182

|

760

|

600

|

550

|

4-φ24

|

340

|

200

|

295

|

12-φ23

|

285

|

150

|

240

|

8-φ23

|

|

200DL288-30

|

4

|

380

|

2795

|

182

|

905

|

600

|

550

|

4-φ24

|

340

|

200

|

295

|

12-φ23

|

285

|

150

|

240

|

8-φ23

|

|

200DL288-30

|

5

|

380

|

2945

|

182

|

1050

|

600

|

550

|

4-φ24

|

340

|

200

|

295

|

12-φ23

|

285

|

150

|

240

|

8-φ23

|

|

200DL288-30

|

6

|

380

|

3095

|

182

|

1200

|

600

|

550

|

4-φ24

|

340

|

200

|

295

|

12-φ23

|

285

|

150

|

240

|

8-φ23

|

Installation Diagram (2)

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Installation Diagram (3)

|

|

|||||||||||||||||||||||||||||||||||||

|

Model

|

Mounting Plate Dimensions

|

Rigid Concrete Base Dimensions

|

||||||||||

|

A×A

|

B×B

|

C×C

|

H

|

d1

|

d2

|

D×D

|

E×E

|

F×F

|

H

|

d

|

h

|

|

|

40DL

|

300

|

540

|

600

|

80

|

φ14 or φ18

|

φ18

|

300

|

500

|

560

|

250

|

60

|

200

|

|

50DL

|

305

|

540

|

600

|

80

|

φ14 or φ18

|

φ18

|

305

|

500

|

560

|

250

|

60

|

200

|

|

65DL

|

370

|

740

|

800

|

80

|

φ14 or φ18

|

φ24

|

370

|

500

|

560

|

250

|

80

|

250

|

|

80DL

|

400

|

740

|

800

|

80

|

φ18 or φ22

|

φ24

|

400

|

600

|

660

|

350

|

80

|

250

|

|

100DL

|

410

|

740

|

800

|

80

|

φ18 or φ22

|

φ24

|

410

|

600

|

660

|

350

|

80

|

250

|

|

150DL

|

550

|

840

|

900

|

80

|

φ18 or φ22

|

φ24

|

550

|

700

|

760

|

350

|

80

|

250

|

|

200DL

|

600

|

840

|

900

|

80

|

φ22

|

φ24

|

600

|

800

|

880

|

350

|

80

|

250

|

OEM & Custom

We offer OEM/ODM customization, including cast iron or stainless steel versions, special voltage (220V/415V/460V), high-temperature configurations, and control cabinet integration. Each pump is tested under ISO and CE standards to ensure performance and reliability for international markets.

FAQs

- Q: What is the main difference between DL and DLR models?

A: DL is for normal-temperature clean water (≤80°C), while DLR is for hot water systems (≤120°C). - Q: What’s the maximum pressure capacity?

A: The pump can withstand up to 2.5 MPa working pressure. - Q: Is this pump suitable for high-rise buildings?

A: Yes, it’s specifically designed for pressurized water supply and circulation in tall buildings. - Q: Can it be used for slightly corrosive liquids?

A: Yes, with stainless-steel wetted parts, it can handle mildly corrosive fluids. - Q: How often should maintenance be done?

A: Lubricate bearings every 500 hours and inspect seals regularly. - Q: Do you provide OEM labeling and packaging?

A: Yes, OEM branding, packaging, and voltage customization are available for export clients. - Q: What are the main export markets?

A: Our DL/DLR pumps are widely exported to Southeast Asia, the Middle East, and South America for municipal, industrial, and agricultural systems.