Product Overview

The FB/AFB stainless steel corrosion-resistant centrifugal pump series is a single-stage, single-suction horizontal centrifugal pump, with wetted parts manufactured from 1Cr18Ni9Ti stainless steel. Featuring a proven hydraulic design, the pump is compact in structure, stable in operation, and suitable for a wide range of corrosive service duties.

The pump and motor are mounted on a common baseplate, allowing straightforward on-site positioning, installation, and maintenance. The series is intended for transferring corrosive or clean liquids free of solid particles, with a maximum liquid temperature of ≤100°C.

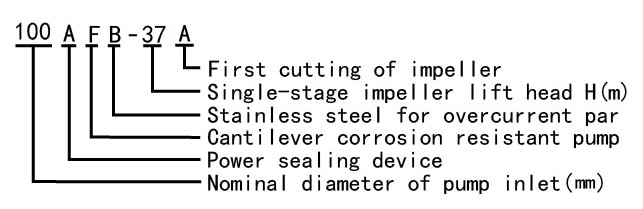

Model Designation

Key Features

Performance Data

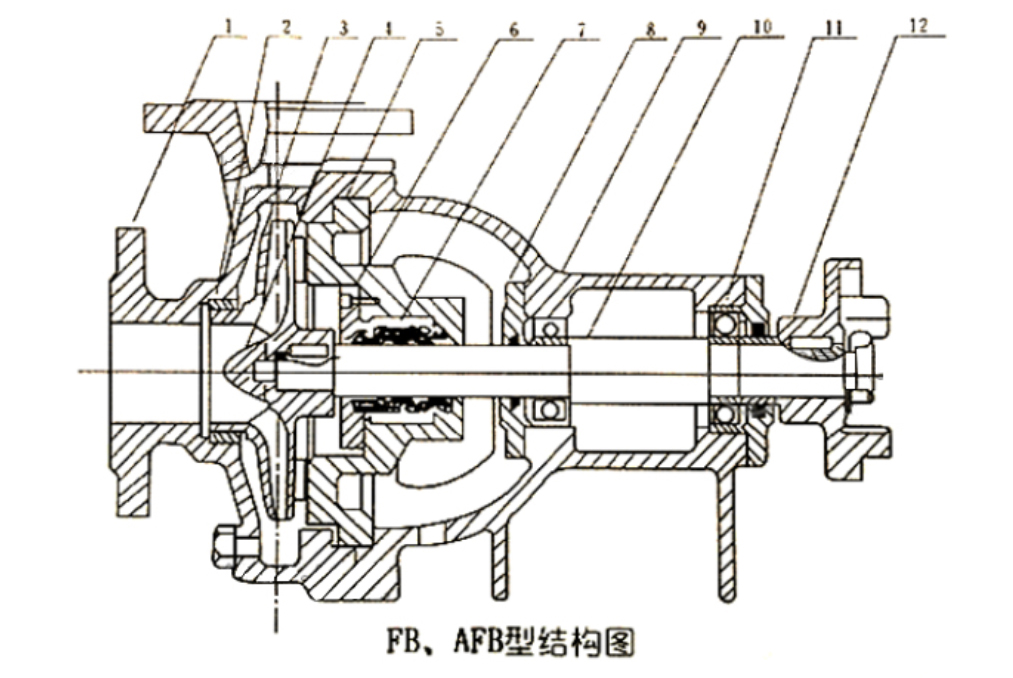

| Item No. | Part Name | Item No. | Part Name |

|---|---|---|---|

| 1 | Pump Casing | 7 | Bearing Housing |

| 2 | Impeller | 8 | Mechanical Seal |

| 3 | Seal Ring | 9 | Coupling |

| 4 | Shaft | 10 | Motor |

| 5 | Cover Plate | 11 | Base Plate |

| 6 | Bearing | 12 | Coupling Guard |

Performance Parameters

|

Model

|

Inlet/Outlet Diameter(mm)

|

Flow Rate(m3/h)

|

Head(m)

|

Motor Power(kw)

|

Speed(r/min)

|

|

25FB-16

|

25×25

|

3.6

|

16

|

1.1

|

2900

|

|

25FB-16A

|

25×25

|

3.27

|

12.5

|

0.75

|

2900

|

|

25FB-25

|

25×25

|

3.6

|

25

|

1.5

|

2900

|

|

25FB-25A

|

25×25

|

3.27

|

20

|

1.1

|

2900

|

|

25FB-40

|

25×25

|

3.6

|

40

|

3

|

2900

|

|

25FB-40A

|

25×25

|

3.27

|

33.5

|

2.2

|

2900

|

|

40FB-16

|

40×32

|

7.2

|

16

|

1.5

|

2900

|

|

40FB-16A

|

40×32

|

6.55

|

12

|

1.1

|

2900

|

|

40FB-20

|

40×32

|

7.2

|

20

|

1.5

|

2900

|

|

40FB-25

|

40×32

|

7.2

|

25

|

2.2

|

2900

|

|

40FB-25A

|

40×32

|

6.55

|

20.5

|

1.5

|

2900

|

|

40FB-40

|

40×32

|

7.2

|

40

|

3

|

2900

|

|

40FB-40A

|

40×32

|

6.55

|

32

|

2.2

|

2900

|

|

40FB-63

|

40×32

|

7.2

|

63

|

7.5

|

2900

|

|

40FB-63A

|

40×32

|

6.72

|

56

|

5.5

|

2900

|

|

Model

|

Inlet/Outlet Diameter(mm)

|

Flow Rate(m3/h)

|

Head(m)

|

Motor Power(kw)

|

Speed(r/min)

|

|

50FB-16

|

50×40

|

14.4

|

16

|

2.2

|

2900

|

|

50FB-16A

|

50×40

|

13.1

|

12

|

1.5

|

2900

|

|

50FB-25

|

50×40

|

14.4

|

25

|

4

|

2900

|

|

50FB-25A

|

50×40

|

13.1

|

20

|

3

|

2900

|

|

50FB-40

|

50×40

|

14.4

|

40

|

5.5

|

2900

|

|

50FB-40A

|

50×40

|

13.1

|

32.5

|

5.5

|

2900

|

|

50FB-63

|

50×40

|

14.4

|

63

|

11

|

2900

|

|

50FB-63A

|

50×40

|

13.1

|

54.5

|

7.5

|

2900

|

|

65FB-25

|

65×50

|

28.8

|

25

|

5.5

|

2900

|

|

65FB-25A

|

65×50

|

26.2

|

20

|

4

|

2900

|

|

65FB-30

|

65×50

|

28.8

|

30

|

7.5

|

2900

|

|

65FB-30A

|

65×50

|

26.2

|

25

|

5.5

|

2900

|

|

65FB-40

|

65×50

|

28.8

|

40

|

11.5

|

2900

|

|

65FB-40A

|

65×50

|

26.2

|

32

|

7.5

|

2900

|

|

65FB-64

|

65×50

|

28.8

|

64

|

15

|

2900

|

|

65FB-64A

|

65×50

|

26.2

|

55

|

7.5

|

2900

|

|

Model

|

Inlet/Outlet Diameter(mm)

|

Flow Rate(m3/h)

|

Head(m)

|

Motor Power(kw)

|

Speed(r/min)

|

|

80FB-15

|

80×65

|

54.4

|

15

|

5.5

|

2900

|

|

80FB-15A

|

80×65

|

49.1

|

11.5

|

4

|

2900

|

|

80FB-24

|

80×65

|

54.4

|

24

|

7.5

|

2900

|

|

80FB-24A

|

80×65

|

49.1

|

19

|

7.5

|

2900

|

|

80FB-38

|

80×65

|

54.4

|

38

|

15

|

2900

|

|

80FB-38A

|

80×65

|

49.1

|

30.5

|

11

|

2900

|

|

80FB-60

|

80×65

|

54.4

|

60

|

22

|

2900

|

|

80FB-60A

|

80×65

|

49.1

|

52

|

18.5

|

2900

|

|

100FB-23

|

100×80

|

100.8

|

23

|

15

|

2900

|

|

100FB-23A

|

100×80

|

91.8

|

17.5

|

11

|

2900

|

|

100FB-37

|

100×80

|

100.8

|

37

|

22

|

2900

|

|

100FB-37A

|

100×80

|

91.8

|

29

|

18.5

|

2900

|

|

100FB-57

|

100×80

|

100.8

|

57

|

37

|

2900

|

|

100FB-57A

|

100×80

|

91.8

|

52

|

37

|

2900

|

|

150FB-22

|

150×100

|

190.8

|

22

|

22

|

2900

|

|

150FB-22A

|

150×100

|

173.5

|

17.5

|

18.5

|

2900

|

|

150FB-35

|

150×100

|

190.8

|

35

|

37

|

2900

|

|

150FB-35A

|

150×100

|

173.5

|

28

|

30

|

2900

|

|

150FB-56

|

150×100

|

190.8

|

56

|

55

|

2900

|

|

150FB-56A

|

150×100

|

173.5

|

50

|

37

|

2900

|

Operating Manual

Installation & Precautions

-

Whether the installation of the IHF single-stage single-suction fluoroplastic alloy chemical pump is reasonable has a highly significant impact on normal operation and service life; therefore, installation and alignment shall be carried out carefully.

-

Pre-embed anchor bolts according to the installation dimensions and complete the concrete foundation work.

-

After the foundation concrete has cured, install the pump on the foundation and use a level to check the level condition of the pump shaft and motor shaft. If not level, adjust with shims until level, then tighten the anchor bolt nuts.

-

Check whether the rotating parts of the pump have any jamming or rubbing. Strictly verify the coaxiality between the pump shaft and the motor shaft; thin shims may be used to adjust for concentricity. Then rotate the coupling by hand—smooth and uniform rotation without rubbing indicates normal installation.

-

The suction and discharge pipelines shall have their own supports. The pipeline weight shall not be borne directly by the pump to avoid damage to the pump casing.

-

If the pump is installed above the liquid level (within the allowable suction lift range), a foot valve shall be installed at the end of the suction line, and a priming filling port (threaded hole) or valve shall be provided on the discharge line for priming before start-up; if the pump is installed below the liquid level, an isolation valve and a strainer shall be installed on the suction line to prevent debris from entering the pump. The strainer area shall be 3–4 times the pipeline cross-sectional area.

-

For high-head pumps, a check valve shall also be installed on the piping outside (downstream of) the outlet flow control valve to prevent damage caused by water hammer during sudden shutdown.

-

The installation elevation must satisfy the pump NPSH requirement, while also considering pipeline losses and medium temperature.

Pump Start-up, Operation, and Shutdown

-

Before start-up, fill the pump with sufficient pumped liquid. Starting without liquid is strictly prohibited.

-

Close the discharge valve. After switching on the power supply, immediately check that the rotation direction matches the arrow indicated on the pump. Reverse rotation is strictly prohibited.

-

After the pump reaches normal speed, gradually open the discharge valve and adjust to the required duty condition for operation. With the discharge valve closed, continuous pump operation shall not exceed 3 minutes.

-

When stopping the pump, first close the discharge valve, then cut off the power supply.

Maintenance & Care

-

Regularly inspect the pump and motor, and replace wearing parts.

-

Frequently replenish the bearing housing with high-quality calcium-based grease to maintain proper bearing lubrication.

-

For long-term shutdown, in addition to draining the corrosive liquid from the pump, thoroughly clean all components and the internal flow passages, and disconnect the power supply.

-

The pump is strictly prohibited from running without liquid (no-load operation).

-

If the medium contains solid particles, a strainer shall be installed at the pump inlet.

Mechanical Seal Use

Mechanical seals are applicable to clean or slightly contaminated media. Before operation, ensure sufficient cooling water flow in the seal chamber and avoid dry running. If leakage occurs, replace the worn seal rings immediately. During disassembly, do not scratch the sealing surfaces. After long-term storage, rotate the shaft by hand before resuming operation.

Corrosion Resistance Rating

• Grade 1: Excellent resistance (annual corrosion rate ≤ 0.1 mm)

• Grade 2: Good resistance (0.1–1.0 mm/year)

• Grade 3: Moderate resistance (1.0–3.0 mm/year)

• Grade 4: Limited resistance (3.0–10 mm/year)

Failure Causes and Solutions

| Failure | Cause | Solution |

|---|---|---|

| No liquid discharge | Pump not filled, air leakage, high suction lift | Refill liquid, check suction line, lower installation height |

| Low flow | Clogged impeller, suction blockage, air in line | Clean impeller and suction pipe |

| Vibration | Motor-pump misalignment, bent shaft | Re-align shaft, replace if needed |

| Overheating | Overload or bearing damage | Reduce load, replace bearings |

| Seal leakage | High inlet pressure | Lower inlet pressure or adjust valve |

OEM & Custom

We provide OEM/ODM customization for voltage (220V/380V/415V), material (304/316L stainless steel), and seal types (mechanical/packing). Optional explosion-proof motors and corrosion-proof coatings are available. All products comply with ISO9001 and CE standards for international export.

FAQs

- Q: What’s the main difference between FB and AFB models?

A: AFB is an upgraded version with enhanced hydraulic efficiency and better corrosion resistance. - Q: What type of media can this pump handle?

A: It can transport clean water, weak acids, alkalis, and corrosive liquids without solid particles. - Q: What is the working temperature range?

A: Up to 100°C for standard configuration. - Q: What’s the maximum efficiency?

A: Up to 78% depending on model and flow range. - Q: Can the material be customized?

A: Yes, options include SS304, SS316, or 1Cr18Ni9Ti based on medium corrosion level. - Q: Do you offer OEM labeling and packaging?

A: Yes, customized logos, colors, and export packaging are available. - Q: What certifications are included?

A: ISO9001 and CE certification for all export products.