Product Overview

The FY Stainless Steel Vertical Chemical Pump is a vertical centrifugal pump based on traditional vertical pump design, incorporating advanced design concepts similar to Sulzer products. Through structural optimization, this pump eliminates the commonly used mechanical seals in traditional vertical pumps and utilizes a specially designed impeller to achieve high efficiency, energy savings, zero leakage, and long service life. It is widely used in industries such as petroleum, chemical processing, pharmaceuticals, paper manufacturing, metallurgy, and wastewater treatment.

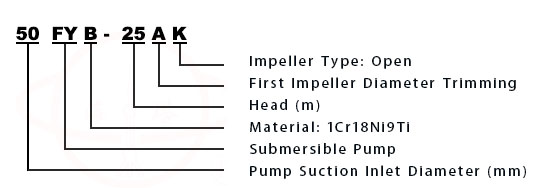

Model Designation

Key Features

-

High Efficiency and Energy Saving: Optimized hydraulic design and impeller configuration ensure stable operation, reduce energy consumption, and extend service life.

-

Zero Leakage Operation: The pump features a seal-less design, eliminating leakage risks and ensuring a truly leak-free operation.

-

Low Vibration: Dual-balanced impeller ensures smooth operation with minimal vibration, extending the pump’s operational lifespan.

-

Versatile Impeller Options: The pump offers both closed and open impeller configurations to handle different media conditions. Open impellers are suitable for handling liquids containing fine solid particles or short fibers, ensuring smooth operation without clogging.

Engineering Overview

The FY Stainless Steel Vertical Chemical Pump uses a vertical installation design, allowing it to be directly installed on storage tanks or containers containing the pumped media. The optimized hydraulic design and impeller configuration ensure stable performance, reduced energy consumption, and extended operational reliability.

Typical Applications

This pump is ideal for the continuous transfer of various chemical liquids, especially in industries such as petroleum, chemical processing, pharmaceuticals, and paper manufacturing. It operates at low frequencies and produces minimal vibration, ensuring smooth operation and reliable liquid transfer.

System Configuration

Pump Components

The FY Stainless Steel Vertical Chemical Pump is composed of the pump casing, impeller assembly, pump shaft, vertical support structure, and drive unit, forming a stable and reliable vertical pumping system designed to meet diverse chemical media transfer needs.

Components and Supply

The pump offers impeller configurations, including both closed and open impellers, to meet different operational requirements. Open impellers are designed to handle media with fine solid particles, ensuring reliable performance and smooth operation.

Technical Service

The FY Stainless Steel Vertical Chemical Pump provides comprehensive technical support, including installation, commissioning, regular maintenance, and troubleshooting services to ensure high efficiency and stable operation over time.

Operating Conditions

-

Applicable Media: Various chemical liquids.

-

Media Temperature Range: -200°C to 140°C.

-

Applicable pH Range: For the cast iron version, the pH range is 5–9.

-

Maximum Solid Particle Size: For pumps equipped with an open impeller, the maximum solid particle size should not exceed 30% of the pump inlet diameter.

Service Conditions

Regular inspection of pump performance is recommended, focusing on the impeller and pump shaft to ensure the system operates reliably and efficiently over time.

Protection Features

The pump is equipped with overcurrent protection, temperature monitoring, and liquid level protection systems to ensure safe and stable operation, preventing damage in case of abnormal conditions.

Selection Standards

When selecting the appropriate pump model, consider factors such as the transfer medium’s temperature, pH value, solid particle size, and the required flow rate and head. Ensure the selection of the most suitable configuration for optimal performance.

Specifications & Installation

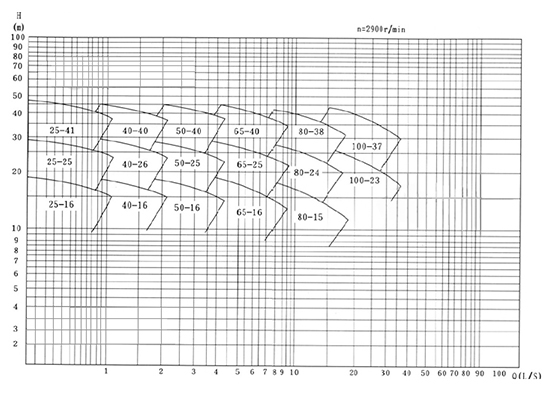

Performance Curves

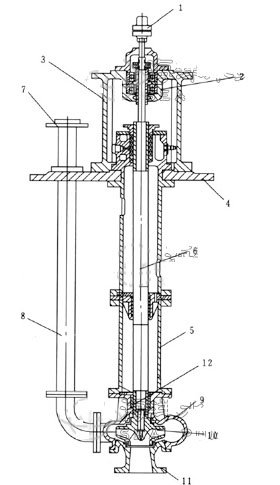

Outline Drawing

Performance Data

|

1

|

Coupling

|

|

2

|

Bearing Housing

|

|

3

|

Lower Support Bracket

|

|

4

|

Mounting Plate

|

|

5

|

Support Tube

|

|

6

|

Shaft

|

|

7

|

Discharge Flange

|

|

8

|

Discharge Pipe

|

|

9

|

Pump Body

|

|

10

|

Impeller

|

|

11

|

Pump Cover

|

|

12

|

Shaft Sleeve

|

Performance Parameters

|

Model

|

Outlet Diameter (mm)

|

Flow Rate (m³/h)

|

Head (m)

(m) |

Speed (rpm)

(r/min) |

Power (kW)

|

||

|

(m3/h)

|

(L/s)

|

Shaft Power

|

Motor Power (kW)

|

||||

|

25FY-16

|

25

|

3.6

|

1

|

16

|

2900

|

0.713

|

1.5

|

|

25FY-16A

|

25

|

3.27

|

0.91

|

13

|

2900

|

0.713

|

1.5

|

|

25FY-25

|

25

|

3.6

|

1

|

25

|

2900

|

1.16

|

2.2

|

|

25FY-25A

|

25

|

3.27

|

0.91

|

20

|

2900

|

1.16

|

2.2

|

|

25FY-41

|

25

|

3.6

|

1

|

41

|

2900

|

2.51

|

4

|

|

25FY-41A

|

25

|

3.27

|

0.91

|

33

|

2900

|

2.51

|

3

|

|

40FY-16

|

32

|

7.2

|

2

|

16

|

2900

|

0.78

|

2.2

|

|

40FY-16A

|

32

|

6.55

|

1.82

|

13

|

2900

|

0.78

|

1.5

|

|

40FY-26

|

32

|

7.2

|

2

|

26

|

2900

|

1.45

|

3

|

|

40FY-26A

|

32

|

6.55

|

1.82

|

21

|

2900

|

1.45

|

3

|

|

40FY-40

|

32

|

7.2

|

2

|

40

|

2900

|

2.53

|

5.5

|

|

40FY-40A

|

32

|

6.55

|

1.82

|

32

|

2900

|

2.53

|

5.5

|

|

50FY-16

|

40

|

14.4

|

4

|

16

|

2900

|

1.18

|

3

|

|

50FY-16A

|

40

|

13.1

|

3.64

|

13

|

2900

|

1.18

|

3

|

|

50FY-25

|

40

|

14.4

|

4

|

25

|

2900

|

1.96

|

4

|

|

50FY-25A

|

40

|

13.1

|

3.64

|

20

|

2900

|

1.96

|

3

|

|

50FY-40

|

40

|

14.1

|

4

|

40

|

2900

|

3.73

|

7.5

|

|

50FY-40A

|

40

|

13.1

|

3.61

|

33

|

2900

|

3.73

|

5.5

|

|

65FY-16

|

50

|

28.8

|

8

|

16

|

2900

|

2.16

|

4

|

|

65FY-16A

|

50

|

26.2

|

7.28

|

13

|

2900

|

2.16

|

3

|

|

65FY-25

|

50

|

28.8

|

8

|

25

|

2900

|

3.56

|

5.5

|

|

65FY-25A

|

50

|

26.2

|

7.28

|

21

|

2900

|

3.56

|

5.5

|

|

65FY-40

|

50

|

28.8

|

8

|

40

|

2900

|

6.04

|

11

|

|

65FY-40A

|

50

|

26.2

|

7.28

|

33

|

2900

|

6.04

|

11

|

|

80FY-15

|

65

|

54

|

15

|

15

|

2900

|

3.34

|

7.5

|

|

80FY-15A

|

65

|

49.1

|

13.65

|

12

|

2900

|

3.34

|

7.5

|

|

80FY-24

|

65

|

54

|

15

|

24

|

2900

|

5.43

|

11

|

|

80FY-24A

|

65

|

49.1

|

13.65

|

20

|

2900

|

5.43

|

11

|

|

80FY-38

|

65

|

54

|

15

|

38

|

2900

|

9.64

|

18.5

|

|

80FY-38A

|

65

|

49.1

|

13.65

|

31

|

2900

|

9.64

|

15

|

|

100FY-23

|

80

|

100.8

|

28

|

23

|

2900

|

9.25

|

18.5

|

|

100FY-23A

|

80

|

91.8

|

25.5

|

18

|

2900

|

9.25

|

15

|

|

100FY-37

|

80

|

100.8

|

28

|

37

|

2900

|

14.73

|

22

|

|

100FY-37A

|

80

|

91.8

|

25.5

|

31

|

2900

|

14.73

|

22

|

Operating Manual

Disassembly & Assembly

-

To replace or inspect the impeller, close the discharge valve, remove the flange bolts and base plate bolts, and lift the pump out of the container using a hoist.

-

Place the base plate vertically on a fixed support, remove all bolts from the pump body, take off the pump cover and impeller nut, and tap the pump body lightly with a hammer to remove the impeller.

-

To replace the sleeve bearing, keep the base plate fixed, remove the motor and corresponding support, then remove the pump coupling, gland, and round nut to extract the shaft sleeve assembly.

-

Assemble in the reverse order of disassembly, ensuring proper alignment and concentricity of all components on the shaft.

Operation & Running

-

After assembling the FY stainless steel chemical sump pump, rotate the coupling by hand to check for smooth movement. Ensure no metal friction noise is present and all nuts are tightened securely.

-

Check the alignment between the pump shaft and motor shaft. The radial deviation of the upper and lower coupling outer circles must not exceed 0.1 mm, and the coupling end-face gap should be kept between 1 mm and 2.5 mm.

-

The distance from the pump inlet to the bottom of the container should be 2–3 times the pump inlet diameter. The distance between the pump body and the container wall should be greater than 2.5 times the inlet diameter.

-

The discharge pipeline must be supported by a separate bracket; its weight must not be borne by the pump.

-

Check the motor’s rotation direction to ensure that the pump rotates in the indicated direction.

-

Close the discharge valve on the pipeline and connect the cooling water line.

-

Start the motor and slowly open the discharge valve to the desired position to begin normal operation.

-

Regularly inspect the pump and motor conditions. Bearing temperature rise should not exceed 75°C, and the bearing housing should contain sufficient grease.

OEM & Custom

We offer comprehensive OEM and ODM customization for FY stainless steel vertical submerged chemical pumps, including corrosion-resistant materials, extended shafts, special coatings, and branded labeling. Each pump can be adapted for unique chemical compositions, high-temperature conditions, or space-limited installations, ensuring long-term reliability and energy efficiency.

FAQs

- Q1: What is the FY vertical chemical pump mainly used for?

It is designed for petroleum, chemical, pharmaceutical, paper making, metallurgy, and sewage treatment industries. - Q2: What are the advantages of the seal-free design?

It prevents leakage, reduces maintenance, and enhances operational reliability compared to traditional mechanical seal pumps. - Q3: Can the FY pump handle corrosive or high-temperature liquids?

Yes, it supports liquids from -20°C to 140°C and can be built with corrosion-resistant stainless steel or alloy materials. - Q4: How does the open impeller type differ?

It is suitable for liquids containing small solids or fibers, preventing clogging and maintaining stable flow. - Q5: How should the pump be installed?

It is vertically mounted on the liquid container, saving floor space and simplifying installation. - Q6: What maintenance does the pump require?

Regular bearing checks, proper lubrication, and ensuring alignment between pump and motor shafts. - Q7: Do you provide OEM and export support?

Yes, OEM, ODM, and private label services are available for international distributors and partners.