Product Overview

The GC horizontal boiler multistage pump is a horizontal, single-suction, segmented multistage centrifugal pump, specifically designed for continuous operation in boiler feedwater and make-up water systems. It features a sectional multistage configuration, allowing head adjustment by changing the number of stages. All critical wetted components, shaft assemblies, sealing structures, and axial thrust balancing devices are optimized to ensure stable water supply, high operational reliability, and easy maintenance.

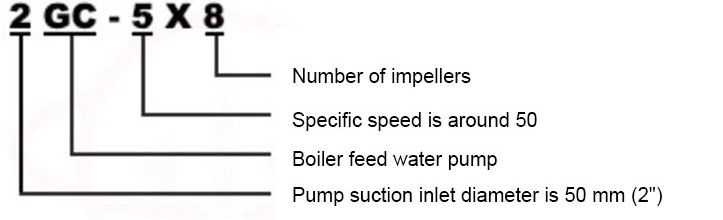

Model Designation

Key Features

-

Multistage sectional structure; for 1½GC to 4GC models, suction and discharge ports are vertically upward, ensuring compact layout and easy installation.

-

Pump head can be adjusted by adding or removing stages, enabling flexible adaptation to various system conditions.

-

Accurate coaxial alignment between impeller outlets and diffuser inlets is essential; improper assembly may reduce efficiency—special care must be taken during maintenance and reassembly.

-

Modular structure facilitates inspection and maintenance; ideal for boiler applications requiring stable continuous operation and scheduled servicing.

Engineering Summary

The GC pump is a horizontal, single-suction, segmented multistage centrifugal pump. The impellers are made of cast iron and statically balanced for smooth rotation. Liquid enters from one side and gains energy through impeller motion. Axial thrust, generated due to pressure difference between impeller sides, is absorbed by a balancing disc assembly.

The shaft is made of high-quality carbon steel; impellers are secured with keys, sleeves, and locking nuts. The shaft end is coupled directly to the motor. Viewed from the drive end, shaft rotation is clockwise.

Seal rings, made of cast iron, are installed at the suction and middle sections to prevent backflow. Axial thrust is balanced by a cast iron balancing disc located between the discharge section and rear cover.

Shaft sleeves are positioned in the stuffing box area to protect the shaft from wear and can be replaced when worn. Bearings are single-row deep groove ball bearings, lubricated with calcium-based grease.

Typical Applications

The GC series is widely used in:

-

Industrial and mining boiler feedwater systems

-

Municipal boiler-based water supply networks

-

Pressure vessel water supply and hot water circulation systems

-

High-rise building water supply and agricultural irrigation

-

Firefighting booster systems and hydraulic cleaning equipment

-

Food processing, pharmaceuticals, chemical plants, aquaculture, environmental projects, and machine tool cooling systems

It is suitable for clean water or non-corrosive liquids with physical and chemical properties similar to water. Maximum allowable medium temperature is 110°C, making it a reliable power unit for continuous water supply and liquid transfer applications.

System & Operation

Components & Supply

-

Main components include shaft, shaft sleeve, suction chamber, impellers, diffusers, seal rings, intermediate section, discharge section, balancing ring, balancing disc, and rear cover.

-

The pump casing consists of cast iron suction, intermediate, discharge, and rear sections forming the complete hydraulic chamber.

-

Impellers feature internal flow channels and are dynamically balanced; energy is imparted via rotation.

-

Seal rings and shaft sleeves are wear parts and replaceable; bearings are deep groove ball bearings, lubricated with calcium grease.

Technical Specifications

Operating Conditions

-

Suitable for clean water or non-corrosive liquids with physical and chemical properties similar to water; kinematic viscosity ≤150 mm²/s.

-

Maximum medium temperature: 110°C.

-

Operating pressure depends on stage count and system conditions; ensure operation within design limits.

-

Rotation direction: Clockwise when viewed from the motor side.

Service Conditions

-

Installation sites should be well-ventilated, free from explosive gases or aggressive media.

-

Indoor installation is recommended; for outdoor setups, appropriate protective measures must be taken.

-

Ambient temperature ≤40°C; relative humidity ≤95%.

-

The foundation must be stable to prevent vibration and ensure long-term performance.

Protection Functions

-

Motors should be equipped with thermal overload protection to prevent damage under abnormal conditions.

-

A check valve is recommended to prevent reverse flow and water hammer during shutdown.

-

Safety relief devices must be installed for high-temperature or high-pressure systems.

-

Optional pressure/flow interlocks can be configured to prevent dry running or off-design operation.

Selection Criteria

-

Select pump model and number of stages based on required head and flow rate, ensuring the duty point falls within the high-efficiency region.

-

Confirm medium temperature and characteristics; use standard configuration for clean water or request custom materials for special media.

-

Consider site conditions, including installation height, layout, and environment, to determine pump form, nozzle orientation, and motor specifications.

-

For systems requiring continuous operation, install standby or redundant pumps for reliability and maintenance.

-

Account for service intervals and component standardization to simplify inspection and reduce downtime.

nstallation & Dimensions

Outline Drawing

Performance Data

|

1

|

Shaft Sleeve Nut

|

2

|

Bearing Cover

|

3

|

Bearing

|

4

|

Front Bearing Housing

|

5

|

Front Shaft Sleeve

|

6

|

Packing Gland

|

7

|

Packing Ring

|

|

8

|

Seal Ring

|

9

|

Suction Section

|

10

|

Impeller

|

11

|

Middle Section

|

12

|

Return Pipe

|

13

|

Discharge Section

|

14

|

Balance Ring

|

|

15

|

Balance Plate

|

16

|

Tail Cover

|

17

|

Rear Shaft Sleeve

|

18

|

Shaft

|

19

|

Round Nut

|

20

|

Tightening Bolt

|

Performance Parameters

|

Model

|

Stages

|

Flow Rate

|

Total Head

|

Rotational Speed

|

Power (kW)

|

Efficiency (η)

|

NPSHr

|

Impeller Diameter

|

Weight

|

||

|

m3/h

|

L/S

|

m

|

r/min

|

Light-load Power

|

Motor Power

|

%

|

m

|

mm

|

Kg

|

||

|

11/2GC-5

|

2

|

6

|

1.66

|

46

|

2950

|

2

|

3

|

38

|

3.7

|

136

|

135

|

|

11/2GC-5

|

3

|

6

|

1.66

|

69

|

2920

|

3

|

4

|

38

|

3.7

|

136

|

147

|

|

11/2GC-5

|

4

|

6

|

1.66

|

92

|

2920

|

4

|

5.5

|

38

|

3.7

|

136

|

174

|

|

11/2GC-5

|

5

|

6

|

1.66

|

115

|

2920

|

5

|

7.5

|

38

|

3.7

|

136

|

204

|

|

11/2GC-5

|

6

|

6

|

1.66

|

138

|

2920

|

6

|

7.5

|

38

|

3.7

|

136

|

212

|

|

11/2GC-5

|

7

|

6

|

1.66

|

161

|

2920

|

7

|

7.5

|

38

|

3.7

|

136

|

220

|

|

11/2GC-5

|

8

|

6

|

1.66

|

184

|

2920

|

8

|

11

|

38

|

3.7

|

136

|

271

|

|

11/2GC-5

|

9

|

6

|

1.66

|

207

|

2920

|

9

|

15

|

38

|

3.7

|

136

|

292

|

|

Model

|

Stages

|

Flow Rate

|

Total Head

|

Rotational Speed

|

Power (kW)

|

Efficiency (η)

|

NPSHr

|

Impeller Diameter

|

Weight

|

||

|

m3/h

|

L/S

|

m

|

r/min

|

Light-load Power

|

Motor Power

|

%

|

m

|

mm

|

Kg

|

||

|

2GC-5

|

2

|

10

|

2.8

|

64

|

2950

|

4.4

|

7.5

|

39.6

|

4.7

|

166

|

258

|

|

2GC-5

|

3

|

10

|

2.8

|

96

|

2950

|

6.6

|

11

|

39.6

|

4.7

|

166

|

309

|

|

2GC-5

|

4

|

10

|

2.8

|

128

|

2950

|

8.8

|

15

|

39.6

|

4.7

|

166

|

389

|

|

2GC-5

|

5

|

10

|

2.8

|

160

|

2950

|

11.0

|

15

|

39.6

|

4.7

|

166

|

414

|

|

2GC-5

|

6

|

10

|

2.8

|

192

|

2950

|

13.2

|

18.5

|

39.6

|

4.7

|

166

|

512

|

|

2GC-5

|

7

|

10

|

2.8

|

224

|

2950

|

15.4

|

22.0

|

39.6

|

4.7

|

166

|

531

|

|

2GC-5

|

8

|

10

|

2.8

|

256

|

2950

|

17.6

|

30.0

|

39.6

|

4.7

|

166

|

589

|

|

2GC-5

|

9

|

10

|

2.8

|

288

|

2950

|

19.8

|

30.0

|

39.6

|

4.7

|

166

|

609

|

|

Model

|

Stages

|

Flow Rate

|

Total Head

|

Rotational Speed

|

Power (kW)

|

Efficiency (η)

|

NPSHr

|

Impeller Diameter

|

Weight

|

||

|

m3/h

|

L/S

|

m

|

r/min

|

Light-load Power

|

Motor Power

|

%

|

m

|

mm

|

Kg

|

||

|

21/2GC-3.5

|

7

|

10

15 20 |

2.8

4.2 5.6 |

336

315 280 |

2950

|

26

28.6 32.5 |

37

|

35

45 47 |

3.3

3.8 4 |

198

|

967

|

|

21/2GC-3.5

|

8

|

10

15 20 |

2.8

4.2 5.6 |

384

360 320 |

2950

|

30

32.8 37 |

45

|

35

45 47 |

3.3

3.8 4 |

198

|

1065

|

|

21/2GC-3.5

|

9

|

10

15 20 |

2.8

4.2 5.6 |

432

405 360 |

2950

|

33.7

37 42 |

55

|

35

45 47 |

3.3

3.8 4 |

198

|

1097

|

|

21/2GC-3.5

|

10

|

10

15 20 |

2.8

4.2 5.6 |

480

450 400 |

2950

|

37.5

41 46.5 |

55

|

35

45 47 |

3.3

3.8 4 |

198

|

1179

|

|

21/2GC-3.5

|

11

|

10

15 20 |

2.8

4.2 5.6 |

528

495 440 |

2950

|

41.5

45 51 |

75

|

35

45 47 |

3.3

3.8 4 |

198

|

1252

|

|

21/2GC-3.5

|

12

|

10

15 20 |

2.8

4.2 5.6 |

576

540 480 |

2950

|

45

49 56 |

75

|

35

45 47 |

3.3

3.8 4 |

198

|

1324

|

|

Model

|

Stages

|

Flow Rate

|

Total Head

|

Rotational Speed

|

Power (kW)

|

Efficiency (η)

|

NPSHr

|

Impeller Diameter

|

Weight

|

||

|

m3/h

|

L/S

|

m

|

r/min

|

Light-load Power

|

Motor Power

|

%

|

m

|

mm

|

Kg

|

||

|

21/2GC-6

|

2

|

15

20 |

4.2

5.6 |

62

54 |

2950

|

5.8

6.2 |

7.5

|

43.7

47.4 |

5

5.3 |

168

|

258

|

|

21/2GC-6

|

3

|

15

20 |

4.2

5.6 |

93

81 |

2950

|

8.7

9.3 |

15

|

43.7

47.4 |

5

5.3 |

168

|

309

|

|

21/2GC-6

|

4

|

15

20 |

4.2

5.6 |

124

108 |

2950

|

11.6

12.4 |

18.5

|

43.7

47.4 |

5

5.3 |

168

|

389

|

|

21/2GC-6

|

5

|

15

20 |

4.2

5.6 |

155

135 |

2950

|

14.5

15.5 |

22.0

|

43.7

47.4 |

5

5.3 |

168

|

494

|

|

21/2GC-6

|

6

|

15

20 |

4.2

5.6 |

186

162 |

2950

|

17.4

18.6 |

22.0

|

43.7

47.4 |

5

5.3 |

168

|

512

|

|

21/2GC-6

|

7

|

15

20 |

4.2

5.6 |

217

189 |

2950

|

20.2

21.7 |

30.0

|

43.7

47.4 |

5

5.3 |

168

|

563

|

|

21/2GC-6

|

8

|

15

20 |

4.2

5.6 |

248

216 |

2950

|

23.2

24.8 |

30.0

|

43.7

47.4 |

5

5.3 |

168

|

589

|

|

21/2GC-6

|

9

|

15

20 |

4.2

5.6 |

279

243 |

2950

|

26.1

27.9 |

37.0

|

43.7

47.4 |

5

5.3 |

168

|

785

|

|

Model

|

Stages

|

Flow Rate

|

Total Head

|

Rotational Speed

|

Power (kW)

|

Efficiency (η)

|

NPSHr

|

Impeller Diameter

|

Weight

|

||

|

m3/h

|

L/S

|

m

|

r/min

|

Light-load Power

|

Motor Power

|

%

|

m

|

mm

|

Kg

|

||

|

4GC-8

|

2

|

30

45 55 |

8.3

12.5 15.3 |

86

82 79 |

2950

|

13.8

16.8 18.1 |

22

|

51

60 62.5 |

4.6

5 5.6 |

192

|

503

|

|

4GC-8

|

3

|

30

45 55 |

8.3

12.5 15.3 |

129

123 114 |

2950

|

20.7

25.2 27.2 |

30

|

51

60 62.5 |

4.6

5 5.6 |

192

|

612

|

|

4GC-8

|

4

|

30

45 55 |

8.3

12.5 15.3 |

172

164 152 |

2950

|

27.6

33.6 35.2 |

45

|

51

60 62.5 |

4.6

5 5.6 |

192

|

835

|

|

4GC-8

|

5

|

30

45 55 |

8.3

12.5 15.3 |

215

205 190 |

2950

|

34.5

42 45.3 |

55

|

51

60 62.5 |

4.6

5 5.6 |

192

|

950

|

|

4GC-8

|

6

|

30

45 55 |

8.3

12.5 15.3 |

258

246 228 |

2950

|

41.4

50.4 54.4 |

55

|

51

60 62.5 |

4.6

5 5.6 |

192

|

1085

|

|

4GC-8

|

7

|

30

45 55 |

8.3

12.5 15.3 |

301

287 266 |

2950

|

48.3

58.8 63.4 |

75

|

51

60 62.5 |

4.6

5 5.6 |

192

|

1087

|

|

4GC-8

|

8

|

30

45 55 |

8.3

12.5 15.3 |

344

328 304 |

2950

|

55

67 73 |

75

|

51

60 62.5 |

4.6

5 5.6 |

192

|

|

|

4GC-8

|

9

|

30

45 55 |

8.3

12.5 15.3 |

387

369 342 |

2950

|

62

75.5 82 |

90

|

51

60 62.5 |

4.6

5 5.6 |

192

|

|

|

4GC-8

|

10

|

30

45 55 |

8.3

12.5 15.3 |

430

410 380 |

2950

|

69

84 91 |

100

|

51

60 62.5 |

4.6

5 5.6 |

192

|

|

Installation Dimensions

Performance Data(2)

|

Model

|

Number of Stages

|

A

|

B

|

C

|

E

|

H

|

I

|

J

|

K

|

L

|

M

|

N

|

O

|

P

|

Q

|

F

|

n-φd

|

|

11/2GC-5

|

2

|

963

|

750

|

510

|

128

|

248

|

122.5

|

355

|

350

|

205

|

365

|

105

|

180

|

315

|

315

|

154

|

4-φ20

|

|

11/2GC-5

|

3

|

1033

|

805

|

535

|

125

|

248

|

172.5

|

355

|

358

|

205

|

405

|

115

|

190

|

355

|

355

|

154

|

4-φ20

|

|

11/2GC-5

|

4

|

1158

|

1010

|

715

|

135

|

248

|

222.5

|

360

|

393

|

205

|

415

|

135

|

210

|

365

|

365

|

47

|

4-φ20

|

|

11/2GC-5

|

5

|

1208

|

1010

|

715

|

135

|

248

|

272.5

|

360

|

393

|

205

|

415

|

135

|

210

|

365

|

365

|

97

|

4-φ20

|

|

11/2GC-5

|

6

|

1258

|

1010

|

715

|

135

|

248

|

322.5

|

360

|

393

|

205

|

415

|

135

|

210

|

365

|

365

|

147

|

4-φ20

|

|

11/2GC-5

|

7

|

1308

1433 |

1060

1180 |

715

760 |

135

170 |

248

|

372.5

|

360

|

393

495 |

205

|

415

470 |

135

163 |

210

255 |

365

|

365

240 |

147

100 |

4-φ20

|

|

11/2GC-5

|

8

|

1484

|

1280

|

785

|

170

|

248

|

422.5

|

395

|

470

|

205

|

470

|

165

|

255

|

365

|

420

|

95

|

4-φ20

|

|

11/2GC-5

|

9

|

1533

|

1280

|

785

|

170

|

248

|

472.5

|

395

|

470

|

205

|

470

|

165

|

255

|

365

|

420

|

145

|

4-φ20

|

|

Model

|

Number of Stages |

A

|

B

|

C

|

E

|

H

|

I

|

J

|

K

|

L

|

M

|

N

|

O

|

P

|

Q

|

F

|

n-φd

|

|

2GC-5

|

2

|

1227

|

915

|

650

|

135

|

325

|

160

|

480

|

443

|

255

|

490

|

135

|

210

|

430

|

430

|

211

|

4-φ24

|

|

2GC-5

|

3

|

1412

|

1160

|

790

|

165

|

325

|

220

|

485

|

490

|

255

|

480

|

165

|

255

|

430

|

430

|

141

|

4-φ24

|

|

2GC-5

|

4

|

1412

|

1160

|

790

|

165

|

325

|

280

|

485

|

490

|

255

|

480

|

165

|

255

|

430

|

430

|

201

|

4-φ24

|

|

2GC-5

|

5

|

1532

|

1220

|

820

|

165

|

325

|

340

|

485

|

490

|

255

|

480

|

165

|

255

|

430

|

430

|

201

|

4-φ24

|

|

2GC-5

|

6

|

1637

|

1320

|

860

|

185

|

325

|

400

|

485

|

490

|

255

|

480

|

165

|

255

|

430

|

430

|

203

|

4-φ24

|

|

2GC-5

|

7

|

1722

|

1380

|

900

|

200

|

325

|

460

|

480

|

510

|

255

|

515

|

180

|

285

|

455

|

455

|

209

|

4-φ24

|

|

2GC-5

|

8

|

1887

|

1575

|

1000

|

240

|

325

|

520

|

525

|

580

|

255

|

585

|

200

|

310

|

440

|

525

|

150

|

4-φ24

|

|

2GC-5

|

9

|

1947

|

1575

|

1000

|

240

|

325

|

580

|

525

|

580

|

255

|

585

|

200

|

310

|

440

|

525

|

210

|

4-φ24

|

|

Model

|

Number of Stages

|

A

|

B

|

C

|

E

|

H

|

I

|

J

|

K

|

L

|

M

|

N

|

O

|

P

|

Q

|

F

|

n-φd

|

|

21/2GC-3.5

|

7

|

1937

|

1590

|

1030

|

225

|

385

|

470

|

608

|

598

|

295

|

600

|

200

|

310

|

540

|

540

|

195

|

4-φ24

|

|

21/2GC-3.5

|

8

|

1937

|

1675

|

1085

|

225

|

385

|

530

|

618

|

638

|

295

|

600

|

225

|

345

|

540

|

540

|

194

|

4-φ24

|

|

21/2GC-3.5

|

9

|

2212

|

1835

|

1170

|

265

|

385

|

590

|

643

|

683

|

295

|

600

|

250

|

385

|

540

|

610

|

192

|

4-φ24

|

|

21/2GC-3.5

|

10

|

2272

|

1895

|

1200

|

265

|

385

|

650

|

643

|

683

|

295

|

600

|

250

|

385

|

540

|

610

|

192

|

4-φ24

|

|

21/2GC-3.5

|

11

|

2402

|

2115

|

1280

|

320

|

385

|

710

|

675

|

750

|

295

|

715

|

280

|

410

|

530

|

655

|

131

|

4-φ24

|

|

21/2GC-3.5

|

12

|

2462

|

2115

|

1280

|

320

|

385

|

770

|

675

|

750

|

295

|

715

|

280

|

410

|

530

|

655

|

191

|

4-φ24

|

|

Model

|

Number of Stages

|

A

|

B

|

C

|

E

|

H

|

I

|

J

|

K

|

L

|

M

|

N

|

O

|

P

|

Q

|

F

|

n-φd

|

|

21/2GC-6

|

2

|

1227

|

915

|

650

|

135

|

325

|

160

|

480

|

443

|

255

|

490

|

135

|

210

|

430

|

430

|

211

|

4-φ24

|

|

21/2GC-6

|

3

|

1412

|

1160

|

790

|

165

|

325

|

220

|

485

|

490

|

255

|

480

|

165

|

255

|

430

|

430

|

141

|

4-φ24

|

|

21/2GC-6

|

4

|

1412

|

1160

|

790

|

165

|

325

|

280

|

485

|

490

|

255

|

480

|

165

|

255

|

430

|

430

|

201

|

4-φ24

|

|

21/2GC-6

|

5

|

1577

|

1320

|

860

|

185

|

325

|

340

|

485

|

490

|

255

|

480

|

165

|

255

|

430

|

430

|

143

|

4-φ24

|

|

21/2GC-6

|

6

|

1662

|

1380

|

900

|

200

|

325

|

400

|

480

|

510

|

255

|

515

|

180

|

285

|

455

|

455

|

149

|

4-φ24

|

|

21/2GC-6

|

7

|

1827

|

1575

|

1000

|

240

|

325

|

460

|

525

|

580

|

255

|

585

|

200

|

310

|

440

|

525

|

90

|

4-φ24

|

|

21/2GC-6

|

8

|

1887

|

1575

|

1000

|

240

|

325

|

520

|

525

|

580

|

255

|

585

|

200

|

310

|

440

|

525

|

150

|

4-φ24

|

|

21/2GC-6

|

9

|

1947

|

1575

|

1000

|

240

|

325

|

525

|

525

|

580

|

255

|

585

|

200

|

310

|

440

|

525

|

210

|

4-φ24

|

|

Model

|

Number of Stages

|

A

|

B

|

C

|

E

|

H

|

I

|

J

|

K

|

L

|

M

|

N

|

O

|

P

|

Q

|

F

|

n-φd

|

|

4GC-8

|

2

|

1552

|

1230

|

845

|

190

|

385

|

190

|

610

|

575

|

295

|

600

|

180

|

285

|

540

|

480

|

185

|

4-φ24

|

|

4GC-8

|

3

|

1732

|

1385

|

925

|

225

|

385

|

265

|

610

|

600

|

295

|

600

|

200

|

310

|

540

|

540

|

185

|

4-φ24

|

|

4GC-8

|

4

|

1847

|

1485

|

980

|

235

|

385

|

340

|

620

|

640

|

295

|

600

|

225

|

345

|

540

|

540

|

184

|

4-φ24

|

|

4GC-8

|

5

|

2037

|

1735

|

1105

|

265

|

385

|

415

|

645

|

685

|

295

|

665

|

250

|

385

|

540

|

605

|

117.5

|

4-φ24

|

|

4GC-8

|

6

|

2112

|

1735

|

1105

|

265

|

385

|

490

|

645

|

685

|

295

|

665

|

250

|

385

|

540

|

605

|

192.5

|

4-φ24

|

|

4GC-8

|

7

|

2257

|

1955

|

1215

|

300

|

385

|

565

|

675

|

750

|

295

|

720

|

280

|

410

|

540

|

660

|

116.5

|

4-φ24

|

|

4GC-8

|

8

|

2332

|

1955

|

1215

|

300

|

385

|

640

|

675

|

750

|

295

|

720

|

280

|

410

|

540

|

660

|

191.5

|

4-φ24

|

|

4GC-8

|

9

|

2457

|

2080

|

1295

|

325

|

385

|

715

|

675

|

750

|

295

|

720

|

280

|

410

|

540

|

660

|

191.5

|

4-φ24

|

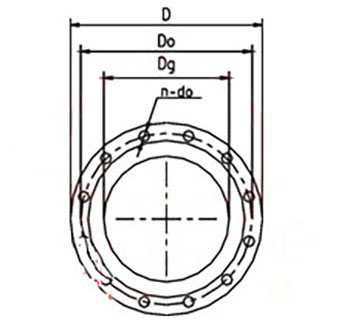

Outline Drawing(2)

Performance Data(2)

|

Size

|

Suction Flange

|

|||

|

Model

|

Dg

|

Do

|

D

|

n-do

|

|

11/2GC-5

|

40

|

115

|

145

|

4-φ18

|

|

2GC-5

|

50

|

125

|

160

|

4-φ18

|

|

21/2GC-6

|

65

|

145

|

180

|

8-φ18

|

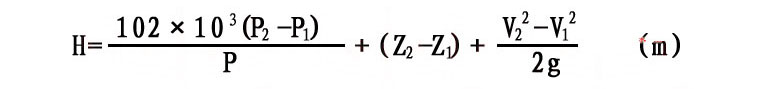

Pump Head Equation:

P1: Inlet

Parameter Definitions and Installation Height Calculation

-

P₂: Outlet pressure of the pump (MPa)

-

Z₁: Vertical distance from inlet pressure gauge to pump shaft center (m)

-

Z₂: Vertical distance from outlet pressure gauge to pump shaft center (m)

-

V₁: Flow velocity at the inlet pressure measurement point (m/s)

-

V₂: Flow velocity at the outlet pressure measurement point (m/s)

-

ρ: Liquid density (kg/m³)

-

g: Gravitational acceleration (9.8 m/s²)

-

Hg: Pump installation height — the vertical distance from the pump shaft centerline to the inlet liquid level (m)

Explanation of Parameters in Installation Height Formula

-

P₀: Atmospheric pressure or absolute pressure at the water surface (expressed in meters of water column)

-

[NPSH]: Net Positive Suction Head required by the pump (m)

-

P′: Vapor pressure of the pumped liquid (in meters of water column)

-

Δh: Head loss in the suction piping (m)

Note:

If the calculated value of Hg is positive, the pump shaft center is above the inlet water level. If negative, the pump operates under suction lift conditions and special attention must be paid to prevent cavitation.

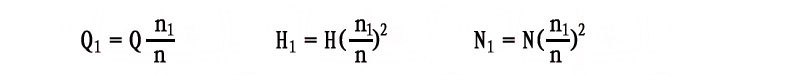

Operating Parameter Note

Pump flow rate (Q), head (H), and shaft power (N) depend on the actual pump speed. Performance parameters should be corrected accordingly based on real operating RPM.

Pump Head Equation:(2)

OEM & Custom

Chaodun Pump provides OEM and ODM customization for GC horizontal multistage pumps. Available in stainless steel or cast iron materials with custom labeling, flange options, and performance configurations. Suitable for distributors and system integrators worldwide.

FAQs

- 1. What are the ideal applications for the GC pump?

Primarily used for boiler feed, hot water circulation, and industrial water systems. - 2. What is the maximum working temperature?

The standard design supports a maximum working temperature of 110°C, with higher temperatures available upon request. - 3. Can the pump handle corrosive liquids?

Yes, it can handle corrosive liquids by customizing the impeller and seal materials for enhanced resistance. - 4. Does Chaodun Pump offer OEM or branding services?

Yes, we offer OEM labeling, color customization, and export packaging services. - 5. What certifications are available for the pumps?

Our pumps are ISO9001 certified, and each unit undergoes comprehensive performance testing before shipment to ensure quality and reliability. - 6. Are Chaodun Pump products customizable?

Yes, we offer flexible customization options, including flow rate, head, and other technical parameters, to meet various application requirements. - 7. What after-sales services does Chaodun Pump provide?

We provide full after-sales support, including installation guidance, maintenance services, and spare parts replacement to ensure long-term reliable operation.