Product Overview

The GW Non-Clogging Vertical Sewage Pump is a vertical centrifugal pump designed for handling media containing solid particles, fibers, and suspended solids. This series offers reliable non-clogging performance and stable solid-liquid transfer capabilities, making it suitable for wastewater treatment and drainage systems with continuous and high-intensity operation demands.

The pump features an optimized single-channel or double-channel impeller design combined with robust mechanical seals, ensuring stable and efficient operation when pumping media containing solid particles and fibers.

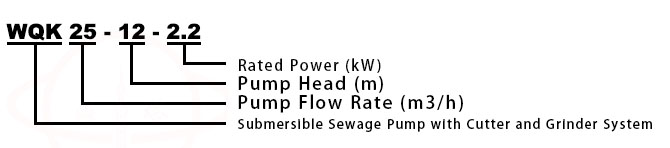

Model Designation

Key Features

-

Single-channel or double-channel impeller design, significantly improving the ability to handle solid particles and fibrous materials, reducing clogging risks.

-

Mechanical seals using advanced friction pair materials, operating in an oil chamber to enhance sealing reliability and ensure long-term stable operation.

-

Compact design with low noise, small footprint, and easy maintenance, facilitating component replacement.

-

Optional automatic control system, enabling automatic start/stop based on liquid level changes, reducing manual intervention.

-

Multiple installation options available, allowing installation and maintenance without entering the sewage pit.

-

Safe operation within the design range, ensuring the motor is not overloaded.

-

Outdoor-rated motor configuration, allowing the pump to be installed outdoors without the need for a pump room, reducing overall installation and construction costs.

Engineering Summary

The GW Non-Clogging Vertical Sewage Pump adopts an optimized design, combining high-efficiency hydraulic performance with high durability, ensuring stable operation when handling wastewater with high solid content and fibrous materials. The pump features a single-channel or double-channel impeller design and is equipped with mechanical seals, effectively handling solids and fibers in wastewater while reducing the risk of clogging. The design and construction of the pump meet relevant performance and vibration control standards, making it ideal for demanding sewage discharge systems.

Typical Applications

The GW Non-Clogging Vertical Sewage Pump is suitable for the following applications:

-

Industrial wastewater discharge and treatment systems

-

Residential sewage pumping stations

-

Municipal sewage treatment plant discharge systems

-

Civil defense and emergency drainage systems

-

Sewage discharge in hospitals, hotels, and public buildings

-

Municipal engineering projects and construction site drainage

-

Auxiliary dewatering in mining operations

-

Rural biogas pits and agricultural irrigation

This pump is designed for handling sewage with solid particles and wastewater, and is also suitable for clean water or mildly corrosive fluids.

System & Operation

Components & Supply

-

Single-channel or double-channel impeller design, improving the ability to handle solid particles and fibrous materials.

-

High abrasion-resistant mechanical seals, ensuring long-term reliable performance.

-

Compact structure with low noise, small footprint, and easy maintenance, enabling quick component replacement.

-

Optional fully automatic control panel for start/stop operation based on liquid level changes, reducing manual intervention.

Technical Specifications

Operating Conditions

-

Liquid Temperature:

• Standard Pump: ≤ 40°C

• Hot Water Pump: ≤ 80°C (special applications can meet up to 120°C) -

Ambient Temperature: ≤ +40°C

-

Maximum Working Pressure: 10 bar

-

Maximum Allowable Inlet Pressure: Limited by system working pressure

-

Fluid Requirements:

• Clean, low-viscosity, non-flammable, sulfur-free liquids, free from solid particles or fibers

• Suitable for pumping mineral water, softened water, purified water, light oils, and mild chemical fluids

• If the liquid’s density or viscosity exceeds that of water, a higher-rated motor should be selected

• The pump’s suitability for specific liquids depends on factors such as chloride content, pH, temperature, and solvent/oil content

Service Conditions

-

Installation Altitude: Must not exceed 1000 meters; for higher elevation applications, specify at the time of order for proper configuration.

-

The pump must not be used in flammable or explosive environments, nor should it handle combustible liquids.

-

Installation should be in a well-ventilated, dry, and vibration-free location.

-

Maximum ambient temperature should not exceed +40°C.

Protection Functions

-

The motor should be equipped with overload protection, phase failure protection, and overheat protection devices to prevent damage under abnormal conditions.

-

Dry-run protection is recommended to prevent mechanical seal failure in case of insufficient water supply.

-

Pressure switches or variable frequency drives (VFDs) should be used to maintain safe pressure ranges.

-

Check valves and anti-backflow devices must be installed to prevent damage caused by reverse flow after shutdown.

Selection Criteria

-

Select the pump model and number of stages based on required flow rate and head.

-

Choose appropriate wetted materials (e.g., SS304, SS316L) based on fluid temperature, pH, and chloride content.

-

Select sealing structure (mechanical seal or packing seal) based on the fluid’s corrosive properties.

-

Ensure installation space and piping layout compatibility with the horizontal configuration.

-

If the pumped liquid has higher viscosity or density than water, a higher-rated motor should be selected to meet the required shaft power.

Installation & Dimensions

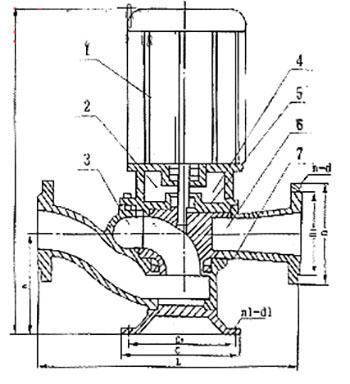

Outline Drawing

Performance Data

|

1

|

Motor

|

|

2

|

Intermediate End Cover

|

|

3

|

Pump Body

|

|

4

|

Water Seal Ring

|

|

5

|

Mechanical Seal

|

|

6

|

Impeller

|

|

7

|

Seal Ring

|

Performance Parameters

|

Model

|

Diameter

|

Flow Rate (m³/h)

|

Head (m)

|

Speed (rpm)

|

Power (kW)

|

Efficiency (%)

|

|

mm

|

(m3/h)

|

(M)

|

(r/min)

|

(kw)

|

(%)

|

|

|

25-7-8-0.55

|

25

|

7

|

8

|

2900

|

0.55

|

45

|

|

25-8-22-1.1

|

25

|

8

|

22

|

2900

|

1.1

|

45

|

|

32-8-12-0.75

|

32

|

8

|

12

|

2900

|

0.75

|

48

|

|

32-12-15-1.1

|

32

|

12

|

15

|

2900

|

1.1

|

45

|

|

40-15-15-1.5

|

40

|

15

|

15

|

2900

|

1.5

|

48

|

|

40-15-30-2.2

|

40

|

15

|

30

|

2900

|

2.2

|

54

|

|

50-20-7-0.75

|

50

|

20

|

7

|

2900

|

0.75

|

51

|

|

50-10-10-0.75

|

50

|

10

|

10

|

2900

|

0.75

|

52

|

|

50-20-15-1.5

|

50

|

20

|

15

|

290

|

1.5

|

53

|

|

50-15-25-2.2

|

50

|

15

|

25

|

2900

|

2.2

|

54

|

|

50-18-30-3

|

50

|

18

|

30

|

2900

|

3

|

55

|

|

50-40-15-4

|

50

|

40

|

15

|

2900

|

4

|

55

|

|

50-25-32-5.5

|

50

|

25

|

32

|

2900

|

5.5

|

55

|

|

50-20-40-7.5

|

50

|

50

|

20

|

2900

|

7.5

|

58

|

|

65-25-15-2.2

|

65

|

25

|

15

|

2900

|

2.2

|

50

|

|

65-37-13-3

|

65

|

37

|

13

|

2900

|

3

|

57

|

|

65-25-30-4

|

65

|

25

|

30

|

2900

|

4

|

61

|

|

65-30-40-7.5

|

65

|

30

|

40

|

2900

|

7.5

|

56

|

|

65-35-50-11

|

65

|

35

|

50

|

2900

|

11

|

45

|

|

65-35-60-15

|

65

|

35

|

60

|

2900

|

15

|

65

|

|

80-40-7-2.2

|

80

|

40

|

7

|

1450

|

2.2

|

59

|

|

80-43-13-3

|

80

|

43

|

13

|

2900

|

3

|

70

|

|

80-40-15-4

|

80

|

40

|

15

|

2900

|

4

|

61

|

|

80-60-13-5.5

|

80

|

60

|

13

|

2900

|

5.5

|

67

|

|

80-65-25-7.5

|

80

|

65

|

25

|

2900

|

7.5

|

63

|

|

Model

|

Diameter

|

Flow Rate (m³/h)

|

Head (m)

|

Speed (rpm) |

Power (kW)

|

Efficiency (%)

|

|

mm

|

(m3/h)

|

(M)

|

(r/min)

|

(kw)

|

(%)

|

|

|

100-80-10-4

|

100

|

100

|

10

|

1450

|

4

|

65

|

|

100-100-15-7.5

|

100

|

100

|

15

|

1450

|

7.5

|

68

|

|

100-80-20-7.5

|

100

|

80

|

20

|

1450

|

7.5

|

65

|

|

100-100-25-11

|

100

|

100

|

25

|

1450

|

11

|

70

|

|

100-100-30-15

|

100

|

100

|

30

|

1450

|

15

|

65

|

|

100-100-35-18.5

|

100

|

100

|

35

|

1450

|

18.5

|

68

|

|

125-130-15-11

|

125

|

130

|

15

|

1450

|

11

|

72

|

|

125-130-20-15

|

125

|

130

|

20

|

1450

|

15

|

75

|

|

150-145-9-7.5

|

150

|

145

|

9

|

1450

|

7.5

|

76

|

|

150-180-15-15

|

150

|

180

|

15

|

1450

|

15

|

69

|

|

150-180-20-18.5

|

150

|

180

|

20

|

1450

|

18.5

|

72

|

|

150-180-25-22

|

150

|

180

|

25

|

1450

|

22

|

78

|

|

150-130-30-22

|

150

|

130

|

30

|

1450

|

22

|

78

|

|

150-180-30-30

|

150

|

180

|

30

|

1450

|

30

|

78

|

|

150-200-30-37

|

150

|

200

|

30

|

1450

|

37

|

73

|

|

200-300-7-11

|

200

|

300

|

7

|

980

|

11

|

66

|

|

200-250-11-15

|

200

|

250

|

11

|

1450

|

15

|

64

|

|

200-250-15-18.5

|

200

|

250

|

15

|

1450

|

18.5

|

73

|

|

200-400-10-22

|

200

|

400

|

10

|

1450

|

22

|

75

|

|

200-400-13-30

|

200

|

400

|

13

|

14501

|

30

|

76

|

|

200-300-15-22

|

200

|

300

|

15

|

1450

|

22

|

76

|

|

200-250-22-30

|

200

|

250

|

22

|

1450

|

30

|

71

|

|

200-350-25-37

|

200

|

350

|

25

|

1450

|

37

|

71

|

|

200-400-30-45

|

200

|

400

|

30

|

1450

|

45

|

74

|

| Model |

Diameter

|

Flow Rate (m³/h)

|

Head (m)

|

Speed (rpm)

|

Power (kW)

|

Efficiency (%)

|

|

mm

|

(m3/h)

|

(M)

|

(r/min)

|

(kw)

|

(%)

|

|

|

250-600-9-30

|

250

|

600

|

9

|

980

|

30

|

78

|

|

250-600-12-37

|

250

|

600

|

12

|

1450

|

37

|

76

|

|

250-600-15-45

|

250

|

600

|

15

|

1450

|

45

|

73

|

|

250-600-20-55

|

250

|

600

|

20

|

1450

|

55

|

73

|

|

250-600-25-75

|

250

|

600

|

25

|

1450

|

75

|

71

|

|

300-800-12-45

|

300

|

800

|

12

|

980

|

45

|

74

|

|

300-480-15-45

|

300

|

480

|

15

|

1450

|

45

|

66

|

|

300-800-15-55

|

300

|

800

|

15

|

1450

|

55

|

73

|

|

300-600-20-55

|

300

|

600

|

20

|

1450

|

55

|

73

|

|

300-800-20-75

|

300

|

800

|

20

|

1450

|

75

|

75

|

|

300-950-20-90

|

300

|

950

|

20

|

1450

|

90

|

76

|

|

300-1000-25-110

|

300

|

1000

|

25

|

1450

|

110

|

76

|

|

300-1100-10-55

|

300

|

1100

|

10

|

1450

|

55

|

73

|

|

350-1500-15-90

|

350

|

1500

|

15

|

740

|

90

|

87

|

|

350-1200-18-90

|

350

|

1200

|

18

|

980

|

90

|

85

|

|

350-1100-28-132

|

350

|

1100

|

28

|

980

|

132

|

84

|

|

350-1000-36-160

|

350

|

1000

|

36

|

980

|

160

|

84

|

|

400-1760-7.5-55

|

400

|

1760

|

7.5

|

980

|

55

|

83

|

|

400-1500-10-75

|

400

|

1500

|

10

|

980

|

75

|

86

|

|

400-2000-13-110

|

400

|

2000

|

13

|

980

|

110

|

84

|

|

400-2000-15-132

|

400

|

2000

|

15

|

980

|

132

|

83

|

|

400-1700-22-160

|

400

|

1700

|

22

|

980

|

160

|

83

|

|

400-1500-26-160

|

400

|

1500

|

26

|

980

|

160

|

84

|

|

Model

|

Diameter

|

Flow Rate (m³/h)

|

Head (m)

|

Speed (rpm)

|

Power (kW)

|

Efficiency (%)

|

|

mm

|

(m3/h)

|

(M)

|

(r/min)

|

(kw)

|

(%)

|

|

|

400-1800-32-250

|

400

|

1800

|

32

|

980

|

250

|

82

|

|

500-2500-10-110

|

500

|

2500

|

10

|

740

|

110

|

85

|

|

500-2600-15-160

|

500

|

2600

|

15

|

740

|

160

|

84

|

|

500-2400-22-220

|

500

|

2400

|

22

|

740

|

220

|

85

|

|

500-2650-24-250

|

500

|

2650

|

24

|

740

|

250

|

85

|

OEM & Custom

OEM/ODM support includes customized voltage and frequency, wetted materials and coatings, mechanical seal brand and options, nameplate and documentation, base/foot dimensions, and connection standards to match local codes. For projects, provide duty point and pipe standards to receive a matched model and BOM quickly.

FAQs

- Is the pump truly “in-line”? Yes. The inlet and outlet share the same center line, allowing installation or removal anywhere along the pipeline.

- How about anti-clog performance? The double-volute flow channel and optimized hydraulics provide smooth passage and stable operation.

- What media and temperature are suitable? Typical sewage/wastewater within pH 5–9 and liquid temperature up to about 60 °C (high-temperature options available).

- What about noise and vibration? The compact coaxial design and double-volute hydraulics reduce vibration and noise versus conventional pumps.

- Any installation notes? Provide independent pipe supports, allow for thermal expansion, and check rotation/clearances before start-up.

- Do you offer OEM customization? Yes. Branding, voltage/frequency, materials, seals, dimensions and standards can be tailored.

- Can it run across the full head range? Yes, it can operate within the whole operating head range without motor overload when correctly selected.