Product Overview

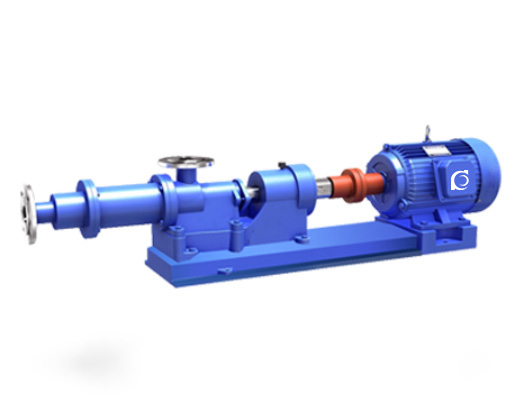

The I-1B Stainless Steel Single Screw Thick Slurry Chemical Pump is a single screw positive displacement rotary pump. It operates by rotating an eccentric single screw rotor inside the stator, continuously transferring slurry from the intake to the discharge outlet. This pump is designed to handle high viscosity, high concentration media, and suspensions containing solid particles.

Key Features

-

High Viscosity and High Concentration Media Handling: Capable of handling high viscosity slurries and suspensions with solid particles.

-

Continuous and Smooth Flow: Provides stable, continuous flow without pulsation, agitation, or leakage.

-

Stable Discharge Pressure: The discharge pressure is independent of the speed and can maintain high discharge pressure even at low flow rates.

-

Powerful Self-Priming Ability: Offers excellent self-priming capability, making it suitable for systems requiring forward and reverse pipeline flushing.

-

Low Vibration and Low Noise: Features low vibration and low noise during operation, ensuring smooth and quiet operation.

Engineering Overview

The I-1B series uses an eccentric rotor and elastomeric locator to form sealing chambers, allowing steady movement of the media along the helical cavity. The pumping process is smooth and continuous, maintaining stable pressure. The discharge pressure is independent of the speed, ensuring high discharge pressure even at low flow rates.

Typical Applications

The I-1B series single screw pump is widely used in:

-

High Viscosity and High Concentration Slurry Transfer: Especially suitable for pumping high viscosity slurries (up to 10000 Pa·S) and suspensions containing solid particles.

-

Precise Flow Control: Ideal for applications requiring precise flow control, such as chemical processing, food production, and pharmaceutical industries.

-

Pipeline Flushing and Water Replacement: Provides forward and reverse flow capabilities, ideal for pipeline flushing and water replacement systems.

System Configuration

Pump Components

The I-1B single screw pump primarily consists of the pump casing, eccentric screw rotor, elastomeric locator, transmission components, and the drive unit. The pump casing can be made of cast iron or stainless steel, and the gearbox and wet parts may be made partially or completely of stainless steel to meet different corrosion resistance and hygiene requirements. The elastomeric materials include wear-resistant rubber, food-grade rubber, and oil-resistant rubber.

Components and Supply

The key components of the I-1B series pump include the eccentric screw rotor, elastomeric locator, drive unit, and transmission components. These parts are made from durable materials to ensure long-term stability and reliability, with customization options available for specific operational conditions.

Technical Service

The I-1B series single screw pump offers comprehensive technical support services, including installation, commissioning, regular maintenance, and troubleshooting to ensure the long-term stability and reliability of the equipment.

Operating Conditions

-

Applicable Media: Suitable for transporting high viscosity slurries, suspensions, and media containing solid particles.

-

Maximum Media Viscosity: ≤10000 Pa·S.

-

Conveying Mode: Continuous positive displacement, providing stable flow.

-

Flow Rate Adjustment: Adjustable flow rate through speed control.

-

Bidirectional Operation: Supports forward and reverse pipeline flushing or water replacement.

Service Conditions

Regular inspection of the pump’s sealing system, eccentric screw, and stator components is recommended to ensure efficient and safe operation and to extend the pump’s service life.

Protection Features

The I-1B series pump is equipped with multiple protection features, including overcurrent protection, temperature monitoring, and liquid level protection systems, ensuring that the pump can stop operating in abnormal conditions to prevent equipment damage.

Selection Standards

When selecting the pump model, consider factors such as the temperature of the media, viscosity, solid particle size, and the required flow and head of the pump to ensure the selection of the most suitable configuration.

Specifications & Installation

Outline Drawing

Performance Data

|

No.

|

Name

|

No.

|

Name

|

No.

|

Name

|

|

1

|

Elbow Connection Pipe

|

5

|

Three-way Pump Body

|

9

|

Hollow Pump Shaft

|

|

2

|

Straight Pipe

|

6

|

Asbestos Packing

|

10

|

Pump Base

|

|

3

|

Rubber Hose

|

7

|

Packing Gland

|

11

|

Pin & Pin Cap

|

|

4

|

Screw Pump Assembly

|

8

|

Flexible Shaft

|

12

|

Coupling

|

Performance Parameters

|

Specification

|

Theoretical Flow Q

|

Flow

|

Head

|

Suction Lift

|

Inlet/Outlet Diameter

|

Speed

|

Motor Power

|

Working Pressure

|

|

Model

|

m³/h

|

t/h

|

m

|

m

|

mm

|

r/min

|

kW

|

kg/cm²

|

|

I-1B 1″

|

2.39

|

1.5

|

50

|

2

|

25

|

960

|

1.1

|

5

|

|

I-1B 1.5″

|

5.2

|

3.2

|

80

|

3

|

40

|

960

|

2.2

|

8

|

|

I-1B 2″

|

8.85

|

5.6

|

80

|

3

|

50

|

960

|

3

|

8

|

|

I-1B 2.5″

|

10.6

|

6.5

|

60

|

3

|

65

|

960

|

3

|

6

|

|

I-1B 3″

|

18.1

|

12

|

60

|

3

|

75

|

960

|

5.5

|

6

|

|

I-1B 4″

|

24

|

16

|

60

|

3

|

100

|

960

|

7.5

|

6

|

|

I-1B 5″

|

36

|

25

|

60

|

3

|

125

|

960

|

11

|

6

|

|

I-1B 6″

|

38

|

30

|

60

|

3

|

150

|

960

|

15

|

6

|

Operating Manual

OEM & Custom

Chaodun Pump provides OEM/ODM customization including special materials (stainless steel grades, food-grade rubber), adjustable drives, and tailored configurations for specific process requirements in food, pharmaceutical, and chemical sectors.

FAQs

- Q1: What is the I-1B Chemical Pump used for?

It is ideal for transferring thick, viscous, or particle-filled liquids in food, chemical, and pharmaceutical industries. - Q2: Is the pump made of stainless steel?

Yes, all wetted parts are made of high-grade stainless steel for corrosion resistance. - Q3: Can it handle high-viscosity fluids?

Yes, up to 10,000 Pa·s viscosity with stable flow performance. - Q4: Is it suitable for food-grade applications?

Yes, food-grade elastomers and materials are available upon request. - Q5: What are the motor drive options?

Direct motor drive, belt drive, and gear reducer drive options are supported. - Q6: What maintenance does it require?

Periodic lubrication, stator inspection, and packing replacement ensure reliable service. - Q7: Can I request a custom configuration or OEM order?

Yes, full OEM and ODM customization is supported by Chaodun Pump.