Product Overview

The IHF single-stage fluoroplastic alloy chemical pump is designed and manufactured in accordance with relevant national standards and is developed on proven non-metallic corrosion-resistant pump technology. The pump adopts a composite construction with a metal casing lined with fluoroplastic (FEP/F46), combining the mechanical strength of metal with the corrosion resistance of fluoroplastic, and is suitable for continuous operation under highly corrosive service conditions.

Model Designation

Key Features

-

Metal casing with FEP (F46) fluoroplastic lining, balancing pressure capability and corrosion resistance, with high-temperature adaptability.

-

High mechanical strength design for stable operation and low vibration.

-

Rational hydraulic and structural configuration for corrosive chemical duties.

-

Reliable mechanical seal arrangement with controlled leakage risk.

-

Easy dismantling and maintenance, suitable for long-term continuous service and life-cycle management.

Engineering Summary

This pump is a single-stage, single-suction centrifugal chemical pump. The core wetted components are manufactured using an integrated process of overall sintering with metal inserts and fluoroplastic compression molding. Through an integrated structural design and composite material configuration, the pump achieves a balanced combination of pressure capability and long-term corrosion resistance, ensuring stable operation over a wide temperature range and in highly corrosive media.

Typical Applications

The IHF single-stage fluoroplastic alloy chemical pump is widely used in:

-

Chemical and pharmaceutical processing

-

Petroleum and petrochemical industries

-

Metallurgy, smelting, and power generation

-

Electroplating, dyes, and pesticide production

-

Pulp and paper, food processing, and textile industries

It is capable of continuous handling of highly corrosive media such as sulfuric acid, hydrochloric acid, hydrofluoric acid, nitric acid, strong alkalis, strong oxidants, and organic solvents. For “any concentration” media, the applicable temperature range is –85°C to 200°C, with reliable operation within this range.

System Configuration

The pump features a rational structural layout that facilitates installation, disassembly, and routine maintenance. A reliable mechanical seal system is adopted; during servicing, sealing parts and wear parts can be replaced independently. This design reduces maintenance complexity and extends overall service life, making the pump suitable for long-term continuous operation.

Components & Supply

The IHF single-stage fluoroplastic alloy chemical pump mainly consists of:

-

Pump Casing: Metal casing with internal FEP (F46) fluoroplastic lining.

-

Impeller & Pump Cover: Metal inserts manufactured via overall sintering and forming, fully encapsulated in fluoroplastic.

-

Shaft Sealing System: Externally mounted metal bellows mechanical seal.

-

Stationary ring material: 99.9% alumina ceramic or silicon carbide

-

Rotating ring material: carbon/graphite composite or silicon carbide

-

Technical Service

Operating Conditions

-

Applicable media: Highly corrosive liquids, including strong acids, strong alkalis, strong oxidants, and organic solvents.

-

Media concentration: No concentration limitation.

-

Operating temperature range: –85°C to 200°C.

-

Duty type: Suitable for continuous, stable operation.

Service Conditions

Stable transfer is supported under highly corrosive media and a wide temperature range. The mechanical seal system allows independent replacement of sealing and wear parts during maintenance, meeting the serviceability requirements of long-term continuous duty.

Protection Functions

A reliable mechanical sealing solution is employed to reduce leakage risk. Together with a serviceable design for sealing and wear parts, it supports inspection and maintenance management and improves operational safety and maintainability for continuous service.

Selection Criteria

Selection should be based on the actual media type (strong acids/alkalis/oxidants/organic solvents), operating temperature range (–85°C to 200°C), and concentration conditions (no limitation), and should be matched with the seal material options (stationary and rotating ring materials) to meet the requirements of continuous, stable operation.

Installation & Dimensions

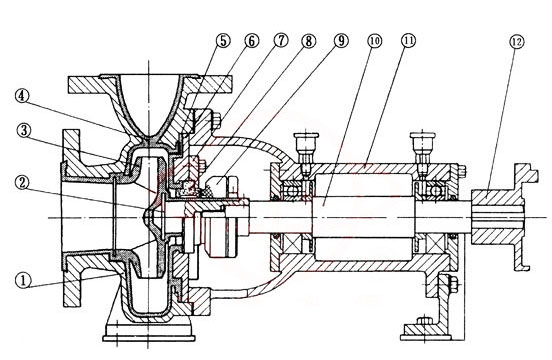

Outline Drawing

Performance Data

|

No.

|

Name

|

No.

|

Name

|

|

1

|

Pump Body

|

7

|

Mechanical Seal Gland

|

|

2

|

Impeller Frame

|

8

|

Stationary Ring

|

|

3

|

Impeller

|

9

|

Rotary Ring

|

|

4

|

Pump Body Lining

|

10

|

Pump Shaft

|

|

5

|

Pump Cover Lining

|

11

|

Bearing Housing

|

|

6

|

Pump Cover

|

12

|

Coupling

|

Performance Parameters

|

Model

|

Speed

|

Flow Rate Q

|

Head

|

Efficiency

|

Power

|

Required NPSH

|

||

|

Shaft Power

|

Motor Power

|

|||||||

|

r/min

|

m3/h

|

L/s

|

m

|

%

|

KW

|

KW

|

m

|

|

|

IHF32-25-125

|

2900

|

3.5

5 6.5 |

0.97

1.39 1.8 |

21

20 18 |

40

44 42 |

0.5

0.62 0.76 |

1.5

|

2.3

|

|

IHF32-25-125A

|

2900

|

3.1

4.5 5.8 |

0.06

1.25 1.61 |

17.6

16 14.4 |

38

41 40 |

0.7

0.48 0.57 |

1.1

|

2.3

|

|

IHF32-25-160

|

2900

|

3.5

5 6.5 |

0.97

1.39 1.8 |

33

32 30 |

34

40 42 |

0.93

1.1 1.26 |

2.2

|

2.3

|

|

IHF32-25-160A

|

2900

|

3.1

4.5 5.8 |

0.86

1.25 1.61 |

29

28 26 |

30

35 36 |

0.81

0.97 1.14 |

1.5

|

2.3

|

|

IHF40-32-125

|

2900

|

4.4

6.5 8.3 |

1.22

1.8 2.31 |

21

20 18 |

40

45 43 |

0.63

0.79 0.95 |

2.2

|

2.5

|

|

IHF40-32-125A

|

2900

|

3.9

5.6 7.4 |

1.08

1.56 2.06 |

17.6

16 14.4 |

38

42 40 |

0.49

0.58 0.72 |

1.5

|

2.5

|

|

IHF40-32-160

|

2900

|

4.4

6.5 8.3 |

1.22

1.8 2.31 |

33

32 30 |

34

40 39 |

1.16

1.42 1.71 |

2.2

|

2.5

|

|

IHF40-32-160A

|

2900

|

3.9

5.6 7.4 |

1.08

1.56 2.06 |

29

28 26 |

32

38 37 |

0.96

1.23 1.41 |

1.5

|

2.5

|

|

Model

|

Speed

|

Flow Rate Q

|

Head

|

Efficiency

|

Power

|

Required NPSH

|

||

|

Shaft Power

|

Motor Power

|

|||||||

|

r/min

|

m3/h

|

L/s

|

m

|

%

|

KW

|

KW

|

m

|

|

|

IHF50-32-125

|

2900

|

8.8

12.5 16.3 |

2.44

3.47 4.53 |

21.5

20 17.5 |

45

54 53 |

1.15

1.26 1.47 |

2.2

|

3.0

|

|

IHF50-32-125A

|

2900

|

8

11 14.5 |

2.22

3.05 4.03 |

17

16 14 |

42

52 51 |

0.88

0.92 1.08 |

1.5

|

3.0

|

|

IHF50-32-160

|

2900

|

8.8

12.5 16.3 |

1.08

1.56 2.06 |

33

32 30 |

41

48 47 |

1.93

2.27 2.84 |

4

|

3.0

|

|

IHF50-32-160A

|

2900

|

8.2

11.7 15.2 |

2.28

3.25 4.22 |

29

28 26 |

39

47 46 |

1.16

1.88 2.34 |

3

|

3.0

|

|

IHF50-32-200

|

2900

|

8.8

12.5 16.3 |

2.44

3.47 4.53 |

52

50 48 |

34

42 41 |

3.7

4.1 5.2 |

7.5

|

3.0

|

|

IHF50-32-200A

|

2900

|

8.2

11.7 15.2 |

2.28

3.25 4.22 |

45

44 42 |

31

40 39 |

3.24

3.5 4.45 |

5.5

|

3.0

|

|

IHF50-32-250

|

2900

|

8.8

12.5 16.3 |

1.08

1.56 2.06 |

82

80 76 |

27

35 34 |

7.3

7.8 10 |

11

|

3.0

|

|

IHF50-32-250A

|

2900

|

8.2

11.7 15.2 |

2.28

3.25 4.22 |

71

70 68 |

25

34 33 |

4.53

6.56 8.52 |

7.5

|

3.0

|

|

Model

|

Speed

|

Flow Rate Q

|

Head

|

Efficiency

|

Power

|

Required NPSH

|

||

|

Shaft Power

|

Motor Power

|

|||||||

|

r/min

|

m3/h

|

L/s

|

m

|

%

|

KW

|

KW

|

m

|

|

|

IHF65-50-125

|

2900

|

17.5

25 32 |

4.86

6.94 8.89 |

21.5

20 17.5 |

56

64 63 |

1.83

2.13 2.42 |

3

|

3.5

|

|

IHF65-50-125A

|

2900

|

15.6

22.3 29 |

4.33

6.19 8.06 |

17

16 14 |

53

62 61 |

1.36

1.57 1.79 |

2.2

|

3.5

|

|

IHF65-50-160

|

2900

|

17.5

25 32 |

4.86

6.94 8.89 |

33

32 27.5 |

50

59 57 |

3.15

3.69 4.2 |

5.5

|

3.5

|

|

IHF65-50-160A

|

2900

|

16.4

23.3 30.4 |

4.56

6.47 8.44 |

29

28 24 |

48

58 56 |

2.7

3.1 3.54 |

4

|

3.5

|

|

IHF65-40-200

|

2900

|

17.5

25 32 |

4.86

6.94 8.89 |

52

50 45.5 |

45

54 54 |

5.5

6.3 7.35 |

11

|

3.5

|

|

IHF65-40-200A

|

2900

|

16.4

23.3 30.4 |

4.56

6.47 8.44 |

46

44 40 |

43

53 52 |

4.3

5 5.2 |

7.5

|

3.5

|

|

IHF65-40-250

|

2900

|

17.5

25 32 |

4.86

6.94 8.89 |

82

80 76 |

39

50 52 |

10.1

10.9 12.74 |

18.5

|

3.5

|

|

IHF65-40-250A

|

2900

|

16.4

23.3 30.4 |

4.56

6.47 8.44 |

71

70 68 |

36

48 50 |

8.8

9.3 11.25 |

15

|

3.5

|

|

Model

|

Speed

|

Flow Rate Q

|

Head

|

Efficiency

|

Power

|

Required NPSH

|

||

|

Shaft Power

|

Motor Power

|

|||||||

|

r/min

|

m3/h

|

L/s

|

m

|

%

|

KW

|

KW

|

m

|

|

|

IHF80-65-125

|

2900

|

35

50 65 |

9.72

13.89 18.06 |

21.5

20 17 |

64

69 67 |

3.2

3.95 4.5 |

5.5

|

4.0

|

|

IHF80-65-125A

|

2900

|

31

45 58 |

31

45 58 |

17

16 14 |

62

68 67 |

2.3

2.88 3.3 |

4

|

4.0

|

|

IHF80-65-160

|

2900

|

35

50 65 |

9.72

13.89 18.06 |

33

32 27.5 |

60

68 67 |

5.24

6.41 7.27 |

11

|

4.0

|

|

IHF80-65-160A

|

2900

|

31

45 58 |

31

45 58 |

29

28 24 |

58

67 66 |

4.3

5 5.2 |

7.5

|

4.0

|

|

IHF80-50-200

|

2900

|

35

50 65 |

9.72

13.89 18.06 |

52

50 48 |

52

64 65 |

9.53

10.64 12.39 |

15

|

4.0

|

|

IHF80-50-200A

|

2900

|

31

45 58 |

31

45 58 |

46

44 40 |

50

63 62 |

7.35

8.56 10 |

11

|

4.0

|

|

IHF80-50-250

|

2900

|

35

50 65 |

9.72

13.89 18.06 |

82

80 72 |

40

50 51 |

19.4

21.8 25 |

30

|

4.0

|

|

IHF80-50-250A

|

2900

|

31

45 58 |

31

45 58 |

71.5

70 63 |

39

50 51 |

15.4

17.6 19.9 |

22

|

4.0

|

|

Model

|

Speed

|

Flow Rate Q

|

Head

|

Efficiency

|

Power

|

Required NPSH

|

||

|

Shaft Power

|

Motor Power

|

|||||||

|

r/min

|

m3/h

|

L/s

|

m

|

%

|

KW

|

KW

|

m

|

|

|

IHF100-80-125

|

2900

|

70

100 130 |

19.4

27.8 36.1 |

23

20 14 |

70

75 65 |

6.26

7.26 7.63 |

11

|

5.0

|

|

IHF100-80-125A

|

2900

|

62.6

89 116 |

17.4

24.7 32.2 |

18

16 11 |

68

73 65 |

4.5

5.3 5.74 |

7.5

|

5.0

|

|

IHF100-80-160

|

2900

|

70

100 130 |

19.4

27.8 36.1 |

33

32 27.5 |

68

74 65 |

9.53

11.78 13.03 |

15

|

5.0

|

|

IHF100-80-160A

|

2900

|

65.4

93.5 121 |

18.2

26 33.6 |

32

28 21 |

66

73 65 |

8.6

9.3 10.6 |

11

|

5.0

|

|

IHF100-65-200

|

2900

|

70

100 130 |

19.4

27.8 36.1 |

52

50 48 |

64

72 71 |

15.5

18.91 20.94 |

30

|

5.0

|

|

IHF100-65-200A

|

2900

|

65.4

93.5 121 |

18.2

26 33.6 |

46

44 40 |

63

71 70 |

13

15.02 17.4 |

22

|

5.0

|

|

IHF100-65-250

|

2900

|

70

100 130 |

19.4

27.8 36.1 |

87

80 68 |

62

69 68 |

26.6

31.6 35 |

45

|

4.0

|

|

IHF100-65-250A

|

2900

|

65.4

93.5 121 |

18.2

26 33.6 |

76.5

70 59 |

60

68 67 |

20.25

26.2 28 |

37

|

4.5

|

|

Model

|

Speed

|

Flow Rate Q

|

Head

|

Efficiency

|

Power

|

Required NPSH

|

||

|

Shaft Power

|

Motor Power

|

|||||||

|

r/min

|

m3/h

|

L/s

|

m

|

%

|

KW

|

KW

|

m

|

|

|

IHF32-25-125

|

1450

|

1.75

2.5 3.25 |

0.49

0.69 0.9 |

5.25

5 4.5 |

37

40 38 |

0.068

0.085 0.105 |

0.75

|

2.3

|

|

IHF32-25-160

|

1450

|

1.75

2.5 3.25 |

0.49

0.69 0.9 |

8.25

8 7.5 |

30

38 40 |

0.131

0.143 0.166 |

0.75

|

2.3

|

|

IHF40-32-125

|

1450

|

2.2

3.25 4.15 |

0.6

0.9 1.15 |

5.25

5 4.5 |

37

41 40 |

0.085

0.108 0.127 |

0.75

|

2.5

|

|

IHF40-32-160

|

1450

|

2.2

2.5 3.25 |

0.6

0.9 1.15 |

8.25

8 7.5 |

33

36 37 |

0.14

0.15 0.18 |

0.75

|

2.5

|

|

Model

|

Speed

|

Flow Rate Q

|

Head

|

Efficiency

|

Power

|

Required NPSH

|

||

|

Shaft Power

|

Motor Power

|

|||||||

|

r/min

|

m3/h

|

L/s

|

m

|

%

|

KW

|

KW

|

m

|

|

|

IHF50-32-125

|

1450

|

4.4

6.25 8.15 |

1.2

1.74 2.26 |

5.37

5 4.37 |

37

46 45 |

0.17

0.18 |

0.75

|

3.0

|

|

IHF50-32-160

|

1450

|

4.4

6.25 8.15 |

1.2

1.74 2.26 |

8.25

8 7.5 |

31

41 42 |

0.31

0.33 0.39 |

0.75

|

3.0

|

|

IHF50-32-200

|

1450

|

4.4

6.25 8.15 |

1.2

1.74 2.26 |

13

12.5 12 |

25

33 36 |

0.62

0.65 0.74 |

1.5

|

3.0

|

|

IHF50-32-250

|

1450

|

4.4

6.25 8.15 |

1.2

1.74 2.26 |

20.5

20 19 |

20

27 30 |

1.22

1.26 1.4 |

2.2

|

3.0

|

|

IHF65-50-125

|

1450

|

17.5

25 32 |

4.86

6.94 8.89 |

5.37

5 4.37 |

45

57 58 |

0.28

0.3 0.33 |

0.75

|

3.5

|

|

IHF65-50-160

|

1450

|

17.5

25 32 |

4.86

6.94 8.89 |

8.25

8 6.87 |

40

53 51 |

0.49

0.51 0.59 |

1.1

|

3.5

|

|

IHF65-40-200

|

1450

|

17.5

25 32 |

4.86

6.94 8.89 |

13

12.5 11.4 |

36

46 47 |

0.86

0.93 1.05 |

1.5

|

3.5

|

|

IHF65-40-250

|

1450

|

17.5

25 32 |

4.86

6.94 8.89 |

20.5

20 19 |

32

42 44 |

1.52

1.62 1.88 |

3

|

3.5

|

|

Model

|

Speed

|

Flow Rate Q

|

Head

|

Efficiency

|

Power

|

Required NPSH

|

||

|

Shaft Power

|

Motor Power

|

|||||||

|

r/min

|

m3/h

|

L/s

|

m

|

%

|

KW

|

KW

|

m

|

|

|

IHF80-65-125

|

1450

|

17.5

25 32 |

4.86

6.94 8.89 |

5.37

5 4.25 |

54

64 62 |

0.47

0.53 0.61 |

1.1

|

4.0

|

|

IHF80-65-160

|

1450

|

17.5

25 32 |

4.86

6.94 8.89 |

8.25

8 7.5 |

50

62 61 |

0.78

0.88 1 |

1.5

|

4.0

|

|

IHF80-50-200

|

1450

|

17.5

25 32 |

4.86

6.94 8.89 |

13

12.5 11.38 |

51

59 58 |

1.21

1.44 1.74 |

3

|

4.0

|

|

IHF80-50-250

|

1450

|

17.5

25 32 |

4.86

6.94 8.89 |

20.5

20 18 |

40

50 51 |

2.4

2.7 3.12 |

4

|

4.0

|

|

IHF100-80-125

|

1450

|

35

50 65 |

9.72

13.89 18.06 |

5.75

5 3.5 |

65

70 64 |

0.85

0.97 0.98 |

1.5

|

4.5

|

|

IHF100-80-160

|

1450

|

35

50 65 |

9.72

13.89 18.06 |

8.5

8 6.5 |

60

68 67 |

1.35

1.6 1.69 |

2.2

|

4.5

|

|

IHF100-65-200

|

1450

|

35

50 65 |

9.72

13.89 18.06 |

13

12.5 10.5 |

60

68 63 |

2.06

2.5 2.95 |

4

|

4.5

|

|

IHF100-65-250

|

1450

|

35

50 65 |

9.72

13.89 18.06 |

21.2

20 18.5 |

58

63 62 |

3

4.3 4.72 |

5.5

|

4.5

|

Operating Manual

OEM & Custom

Chaodun Pump provides OEM and ODM customization including F46 lining thickness adjustments, special mechanical seal configurations, and motor-matched drive solutions for different chemical applications. Customization is available for temperature, pressure, and corrosion resistance requirements.

FAQs

- Q1: What is the IHF Chemical Pump used for?

It is designed for transferring strong corrosive acids, alkalis, and chemical solutions in industrial applications. - Q2: What materials are used in the pump?

The casing is lined with F46 fluoroplastic, and the impeller and cover are fully encapsulated with fluoroplastic alloy. - Q3: What is the operating temperature range?

From -85°C to 200°C depending on the medium. - Q4: Is the pump suitable for high-concentration acids?

Yes, it can handle strong acids like H₂SO₄, HCl, HF, and HNO₃. - Q5: What seal type does it use?

External bellows mechanical seal with ceramic or silicon carbide rings. - Q6: Does Chaodun Pump offer OEM and custom solutions?

Yes, full OEM/ODM services are available including customized materials and configurations. - Q7: What industries commonly use the IHF pump?

Chemical, pharmaceutical, metallurgy, electroplating, food, textile, and wastewater treatment industries.