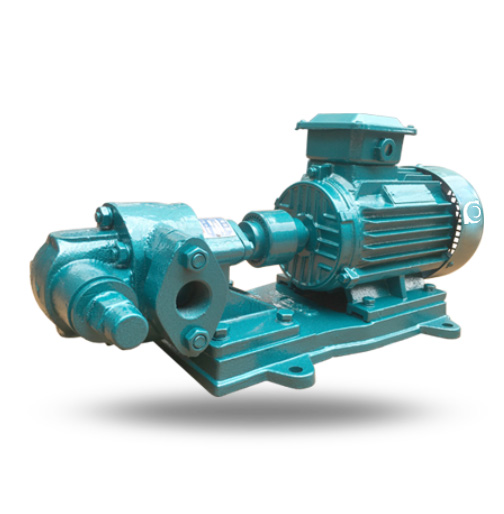

Product Overview

The KCB Gear Oil Pump is specifically designed for transporting lubricating oils with a medium temperature not exceeding 70°C. For high-temperature applications, the pump can be configured with high-temperature materials, typically capable of handling up to 200°C, with options for higher service temperatures. This pump is suitable for liquids with a kinematic viscosity ranging from 5×10⁻⁵ to 1.5×10⁻³ m²/s.

Not suitable for corrosive liquids, liquids containing hard particles or fibers, highly volatile liquids, or low flashpoint liquids (such as gasoline or benzene).

Model Designation

Specifications & Installation

Performance Parameters

|

Model

|

Motor Power (KW)

|

Speed (r/min)

|

Flow (L/min)

|

Discharge Pressure (MPa/cm2)

|

Max Suction Vacuum (m)

|

Inlet/Outlet Diameter

|

|

KCB18.3 (2CY-1.1/14.5-2)

|

1.5

|

1400

|

18.3

|

1.45

|

5

|

3/4″

|

|

KCB33.3 (2CY-2/14.5-2)

|

2.2

|

1420

|

33.3

|

1.45

|

5

|

3/4″

|

|

KCB55 (2CY-3.3/3.3-2)

|

1.5

|

1400

|

55

|

0.33

|

5

|

1″

|

|

KCB55 (2CY-3.3/3.5-2)

|

2.2

|

1420

|

55

|

0.5

|

5

|

1″

|

|

KCB83.3 (2CY-5/3-2)

|

2.2

|

1420

|

83.3

|

0.33

|

5

|

1.5″

|

|

KCB83.3 (2CY-5/5-2)

|

3

|

1420

|

83.3

|

0.5

|

5

|

1.5″

|

|

KCB200 (2CY-8/3.3-2)

|

4

|

1440

|

200

|

0.33

|

5

|

2″

|

|

KCB200 (2CY-12/1.3-2)

|

4

|

1440

|

200

|

0.13

|

5

|

2″

|

|

KCB200 (2CY-12/3.3-2)

|

5.5

|

1440

|

200

|

0.33

|

5

|

2″

|

|

KCB200 (2CY-12/6-2)

|

5.5

|

1440

|

200

|

0.60

|

5

|

2″

|

|

KCB200 (2CY-12/10-2)

|

7.5

|

1440

|

200

|

1.00

|

5

|

2″

|

Operating Manual

Installation

-

Before installation, check whether the pump has been damaged during transportation, ensuring the motor is not damp and that the dust covers on the pump inlet and outlet are intact.

-

Before installing the pipeline, clean the inner walls of the pipe using water or steam to remove any dirt or impurities. Ensure the pump does not bear the weight of the pipeline to avoid affecting the pump’s precision.

-

The pipeline connections must be sealed to ensure the pump can properly draw liquid, preventing suction issues.

-

To prevent debris from entering the pump, install a metal filter at the suction inlet.

Operation & Running

-

Check that all fasteners are securely tightened.

-

Ensure the drive shaft rotates smoothly.

-

Confirm that the intake and outlet valves are fully open.

-

Verify the correct rotation direction of the pump (viewing from the pump end towards the motor, it should rotate counterclockwise).

Precautions

-

Monitor the pressure and vacuum gauge readings to ensure they remain within the specified range.

-

Check the stuffing box. If leakage occurs, tighten the stuffing box cover (but avoid over-tightening to prevent overheating and rapid wear of the sealing ring).

-

If abnormal noise or excessive temperature rise occurs during operation, immediately stop the pump and investigate the cause.

-

Do not adjust the safety valve arbitrarily. If adjustment is needed, use instruments to calibrate the safety valve to the appropriate pressure setting.

Stopping the Pump

-

Turn off the power supply.

-

Close the intake and outlet valves.

OEM & Custom

We offer OEM branding, stainless steel versions, copper gear options, high-temperature models, custom seals, custom port sizes, special-voltage motors, and export-grade packaging.

FAQs

- 1. What liquids can the KCB/2CY pump handle?

Lubricating oil, diesel, heavy oil, and clean non-corrosive oils. - 2. Can it handle corrosive liquids?

Yes, if using stainless steel gear pump versions. - 3. Does it require priming?

No, the pump has strong self-priming capability. - 4. Is a safety valve included?

Yes, all pumps include an integrated safety valve for over-pressure protection. - 5. What is the maximum temperature?

Standard ≤70°C; high-temperature versions up to 200–300°C. - 6. What seal types are available?

Packing seal, rubber seal, skeleton seal, and graphite packing. - 7. Can you provide OEM customization?

Yes, including materials, voltage, seals, gears, and branding.