Product Overview

The LG vertical, easy-dismantling multistage clean-water pump is an integrated vertical multistage pump unit developed for constant-pressure water supply in high-rise buildings and for fire-fighting duties. Based on a proven hydraulic design, it delivers high efficiency and stable head–capacity characteristics, making it suitable for continuous operation with low noise and long service life. The vertical multistage configuration provides a compact footprint and enables straightforward integration into building booster systems and packaged pump sets. With a lightweight, service-friendly component layout, the unit is well suited for engineering installations in building water supply, drainage, and building services systems.

Model Designation

Key Features

- Compact vertical multistage structure with a small footprint, suitable for building water systems; optional outdoor protection cover supports flexible installation scenarios.

- Impellers directly mounted on motor shaft ensure coaxial operation, enhancing stability and extending equipment service life.

- High-quality mechanical seal or cartridge seal, equipped with hard alloy sealing rings for improved wear resistance and extended seal durability.

- Equal-diameter suction/discharge ports, support for series or parallel pump operation, configurable inlet/outlet orientation (0°, 90°, 180°, 270°), and head adjustability via stage modification or impeller trimming.

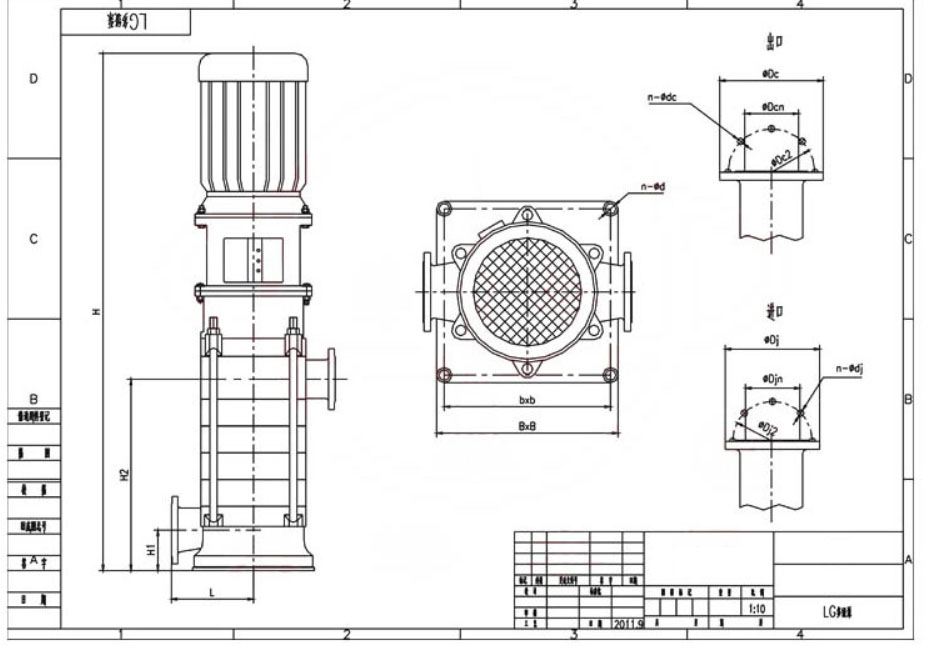

Installation Dimensions/Size

Outline Drawing

Pump Parts & Materials List

| Item No. | Component Name | Material / Model | Item No. | Component Name | Material / Model |

|---|---|---|---|---|---|

| 1 | Motor | Y Series (V5), 2-Pole | 9 | Shaft Sleeve | Q235 |

| 2 | Motor Bracket | HT200 | 10 | Middle Section | HT200 |

| 3 | Coupling | HT200 | 11 | Diffuser | HT200 |

| 4 | Mechanical Seal Cover | HT200 | 12 | Impeller | HT200 |

| 5 | Air Release Valve | Copper Alloy | 13 | Shaft | 45 Steel / 2Cr13 |

| 6 | Mechanical Seal | 120A | 14 | Bearing | Tin Bronze |

| 7 | Final Diffuser | HT200 | 15 | Suction Section | HT200 |

| 8 | Discharge Section | HT200 |

Performance Parameters

|

Model

|

Stages

|

Flow

|

Head

|

Speed

|

Motor Power

|

Efficiency

|

Weight

|

Required

|

|

(m3/h)

|

(M)

|

(r/min)

|

(kw)

|

(%)

|

Kg

|

NPSH(m)

|

||

|

25LG(R)3-10*2

|

2

|

3

|

20

|

2900

|

0.75

|

42

|

70

|

2.0

|

|

25LG(R)3-10*3

|

3

|

3

|

30

|

2900

|

1.1

|

42

|

74

|

2.0

|

|

25LG(R)3-10*4

|

4

|

3

|

40

|

2900

|

1.5

|

42

|

85

|

2.0

|

|

25LG(R)3-10*5

|

5

|

3

|

50

|

2900

|

1.5

|

42

|

89

|

2.0

|

|

25LG(R)3-10*6

|

6

|

3

|

60

|

2900

|

2.2

|

42

|

100

|

2.0

|

|

25LG(R)3-10*7

|

7

|

3

|

70

|

2900

|

2.2

|

42

|

104

|

2.0

|

|

25LG(R)3-10*8

|

8

|

3

|

80

|

2900

|

2.2

|

42

|

108

|

2.0

|

|

25LG(R)3-10*9

|

9

|

3

|

90

|

2900

|

2.2

|

42

|

112

|

2.0

|

|

25LG(R)3-10*10

|

10

|

3

|

100

|

2900

|

3

|

42

|

125

|

2.0

|

|

25LG(R)3-10*11

|

11

|

3

|

110

|

2900

|

3

|

42

|

129

|

2.0

|

|

25LG(R)3-10*12

|

12

|

3

|

120

|

2900

|

4

|

42

|

145

|

2.0

|

|

25LG(R)3-10*13

|

13

|

3

|

130

|

2900

|

4

|

42

|

149

|

2.0

|

|

25LG(R)3-10*14

|

14

|

3

|

140

|

2900

|

4

|

42

|

153

|

2.0

|

|

25LG(R)3-10*15

|

15

|

3

|

150

|

2900

|

4

|

42

|

157

|

2.0

|

|

Model

|

Stages

|

Flow

|

Head

|

Speed

|

Motor Power

|

Efficiency

|

Weight

|

Required

|

|

(m3/h)

|

(M)

|

(r/min)

|

(kw)

|

(%)

|

Kg

|

NPSH(m)

|

||

|

32LG(R)6.5-15*2

|

2

|

6.5

|

30

|

2900

|

1.5

|

53

|

90

|

2.4

|

|

32LG(R)6.5-15*3

|

3

|

6.5

|

45

|

2900

|

2.2

|

53

|

100

|

2.4

|

|

32LG(R)6.5-15*4

|

4

|

6.5

|

60

|

2900

|

3

|

53

|

115

|

2.4

|

|

32LG(R)6.5-15*5

|

5

|

6.5

|

75

|

2900

|

4

|

53

|

135

|

2.4

|

|

32LG(R)6.5-15*6

|

6

|

6.5

|

90

|

2900

|

4

|

53

|

142

|

2.4

|

|

32LG(R)6.5-15*7

|

7

|

6.5

|

105

|

2900

|

5.5

|

53

|

175

|

2.4

|

|

32LG(R)6.5-15*8

|

8

|

6.5

|

120

|

2900

|

5.5

|

53

|

182

|

2.4

|

|

32LG(R)6.5-15*9

|

9

|

6.5

|

135

|

2900

|

5.5

|

53

|

190

|

2.4

|

|

32LG(R)6.5-15*10

|

10

|

6.5

|

150

|

2900

|

7.5

|

53

|

210

|

2.4

|

|

40LG(R)12-15*2

|

2

|

12

|

30

|

2900

|

2.2

|

60

|

90

|

2.9

|

|

40LG(R)12-15*3

|

3

|

12

|

45

|

2900

|

3

|

60

|

105

|

2.9

|

|

40LG(R)12-15*4

|

4

|

12

|

60

|

2900

|

4

|

60

|

130

|

2.9

|

|

40LG(R)12-15*5

|

5

|

12

|

75

|

2900

|

5.5

|

60

|

155

|

2.9

|

|

40LG(R)12-15*6

|

6

|

12

|

90

|

2900

|

5.5

|

60

|

163

|

2.9

|

|

40LG(R)12-15*7

|

7

|

12

|

105

|

2900

|

7.5

|

60

|

180

|

2.9

|

|

40LG(R)12-15*8

|

8

|

12

|

120

|

2900

|

7.5

|

60

|

190

|

2.9

|

|

40LG(R)12-15*9

|

9

|

12

|

135

|

2900

|

11

|

60

|

215

|

2.9

|

|

40LG(R)12-15*10

|

10

|

12

|

150

|

2900

|

11

|

60

|

225

|

2.9

|

|

Model

|

Stages

|

Flow

|

Head

|

Speed

|

Motor Power

|

Efficiency

|

Weight

|

Required

|

|

(m3/h)

|

(M)

|

(r/min)

|

(kw)

|

(%)

|

Kg

|

NPSH(m)

|

||

|

50LG(R)24-20*2

|

2

|

24

|

40

|

2900

|

5.5

|

69

|

160

|

3.2

|

|

50LG(R)24-20*3

|

3

|

24

|

60

|

2900

|

7.5

|

69

|

180

|

3.2

|

|

50LG(R)24-20*4

|

4

|

24

|

80

|

2900

|

11

|

69

|

250

|

3.2

|

|

50LG(R)24-20*5

|

5

|

24

|

100

|

2900

|

11

|

69

|

260

|

3.2

|

|

50LG(R)24-20*6

|

6

|

24

|

120

|

2900

|

15

|

69

|

280

|

3.2

|

|

50LG(R)24-20*7

|

7

|

24

|

140

|

2900

|

15

|

69

|

290

|

3.2

|

|

50LG(R)24-20*8

|

8

|

24

|

160

|

2900

|

18.5

|

69

|

315

|

3.2

|

|

65LG(R)36-20*2

|

2

|

36

|

40

|

2900

|

7.5

|

72

|

170

|

3.4

|

|

65LG(R)36-20*3

|

3

|

36

|

60

|

2900

|

11

|

72

|

230

|

3.4

|

|

65LG(R)36-20*4

|

4

|

36

|

80

|

2900

|

15

|

72

|

250

|

3.4

|

|

65LG(R)36-20*5

|

5

|

36

|

100

|

2900

|

18.5

|

72

|

280

|

3.4

|

|

65LG(R)36-20*6

|

6

|

36

|

120

|

2900

|

22

|

72

|

330

|

3.4

|

|

65LG(R)36-20*7

|

7

|

36

|

140

|

2900

|

22

|

72

|

345

|

3.4

|

|

65LG(R)36-20*8

|

8

|

36

|

160

|

2900

|

30

|

72

|

395

|

3.4

|

|

Model

|

Stages

|

Flow

|

Head

|

Speed

|

Motor Power

|

Efficiency

|

Weight

|

Required

|

|

(m3/h)

|

(M)

|

(r/min)

|

(kw)

|

(%)

|

Kg

|

NPSH(m)

|

||

|

80LG(R)50-20*2

|

2

|

50

|

40

|

2900

|

11

|

73

|

250

|

3.4

|

|

80LG(R)50-20*3

|

3

|

50

|

60

|

2900

|

15

|

73

|

280

|

3.4

|

|

80LG(R)50-20*4

|

4

|

50

|

80

|

2900

|

18.5

|

73

|

310

|

3.4

|

|

80LG(R)50-20*5

|

5

|

50

|

100

|

2900

|

22

|

73

|

360

|

3.4

|

|

80LG(R)50-20*6

|

6

|

50

|

120

|

2900

|

30

|

73

|

440

|

3.4

|

|

80LG(R)50-20*7

|

7

|

50

|

140

|

2900

|

30

|

73

|

460

|

|

|

80LG(R)50-20*8

|

8

|

50

|

160

|

2900

|

37

|

73

|

490

|

|

|

100LG72-20*2

|

2

|

72

|

40

|

2900

|

11

|

73

|

260

|

3.5

|

|

100LG72-20*3

|

3

|

72

|

60

|

2900

|

18.5

|

73

|

290

|

3.5

|

|

100LG72-20*4

|

4

|

72

|

80

|

2900

|

22.0

|

73

|

380

|

3.5

|

|

100LG72-20*5

|

5

|

72

|

100

|

2900

|

30.0

|

73

|

450

|

3.5

|

|

100LG72-20*6

|

6

|

72

|

120

|

2900

|

37.0

|

73

|

470

|

3.5

|

|

100LG72-20*7

|

7

|

72

|

140

|

2900

|

45.0

|

73

|

520

|

3.5

|

|

100LG72-20*8

|

8

|

72

|

160

|

2900

|

45.0

|

73

|

540

|

3.5

|

|

100LG72-20*9

|

9

|

72

|

180

|

2900

|

55.0

|

73

|

3.5

|

|

|

Model

|

Stages

|

Flow

|

Head

|

Speed

|

Motor Power

|

Efficiency

|

Weight

|

Required

|

|

(m3/h)

|

(M)

|

(r/min)

|

(kw)

|

(%)

|

Kg

|

NPSH(m)

|

||

|

100LG100-20*2

|

2

|

100

|

40

|

2900

|

18.5

|

76

|

3.7

|

|

|

100LG100-20*3

|

3

|

100

|

60

|

2900

|

30

|

76

|

3.7

|

|

|

100LG100-20*4

|

4

|

100

|

80

|

2900

|

37

|

76

|

3.7

|

|

|

100LG100-20*5

|

5

|

100

|

100

|

2900

|

45

|

76

|

3.7

|

|

|

100LG100-20*6

|

6

|

100

|

120

|

2900

|

55

|

76

|

3.7

|

|

|

100LG100-20*7

|

7

|

100

|

140

|

2900

|

75

|

76

|

3.7

|

|

|

100LG100-20*8

|

8

|

100

|

160

|

2900

|

75

|

76

|

3.7

|

|

|

150LG150-20*2

|

2

|

150

|

40

|

2900

|

30

|

77

|

4.1

|

|

|

150LG150-20*3

|

3

|

150

|

60

|

2900

|

37

|

77

|

4.1

|

|

|

150LG150-20*4

|

4

|

150

|

80

|

2900

|

45

|

77

|

4.1

|

|

|

150LG150-20*5

|

5

|

150

|

100

|

2900

|

55

|

77

|

4.1

|

|

|

150LG150-20*6

|

6

|

150

|

120

|

2900

|

75

|

77

|

4.1

|

|

|

150LG150-20*7

|

7

|

150

|

140

|

2900

|

90

|

77

|

4.1

|

|

|

150LG150-20*8

|

8

|

150

|

160

|

2900

|

90

|

77

|

4.1

|

|

|

150LG150-20*9

|

9

|

150

|

180

|

2900

|

110

|

77

|

4.1

|

|

|

150LG150-20*10

|

10

|

150

|

200

|

2900

|

132

|

77

|

4.1

|

Installation Diagram

Installation Dimensions(1)

|

Model |

Stages

|

L

|

H

|

H1

|

H2

|

B

|

b

|

n-φd

|

Inlet Flange

|

Outlet Flange

|

||||||

|

Dj

|

Djn

|

Dj2

|

n-dj

|

Dc

|

Dcn

|

Dc2

|

n-φdc

|

|||||||||

|

25LG(R)3-10

|

2

|

130

|

630

|

85

|

180

|

230

|

190

|

4-φ18

|

115

|

25

|

85

|

4-M12

|

115

|

25

|

85

|

4-φ14

|

|

25LG(R)3-10

|

3

|

130

|

670

|

85

|

220

|

230

|

190

|

4-φ18

|

115

|

25

|

85

|

4-M12

|

115

|

25

|

85

|

4-φ14

|

|

25LG(R)3-10

|

4

|

130

|

710

|

85

|

260

|

230

|

190

|

4-φ18

|

115

|

25

|

85

|

4-M12

|

115

|

25

|

85

|

4-φ14

|

|

25LG(R)3-10

|

5

|

130

|

755

|

85

|

305

|

230

|

190

|

4-φ18

|

115

|

25

|

85

|

4-M12

|

115

|

25

|

85

|

4-φ14

|

|

25LG(R)3-10

|

6

|

130

|

825

|

85

|

340

|

230

|

190

|

4-φ18

|

115

|

25

|

85

|

4-M12

|

115

|

25

|

85

|

4-φ14

|

|

25LG(R)3-10

|

7

|

130

|

865

|

85

|

380

|

230

|

190

|

4-φ18

|

115

|

25

|

85

|

4-M12

|

115

|

25

|

85

|

4-φ14

|

|

25LG(R)3-10

|

8

|

130

|

900

|

85

|

425

|

230

|

190

|

4-φ18

|

115

|

25

|

85

|

4-M12

|

115

|

25

|

85

|

4-φ14

|

|

25LG(R)3-10

|

9

|

130

|

945

|

85

|

460

|

230

|

190

|

4-φ18

|

115

|

25

|

85

|

4-M12

|

115

|

25

|

85

|

4-φ14

|

|

25LG(R)3-10

|

10

|

130

|

1020

|

85

|

500

|

230

|

190

|

4-φ18

|

115

|

25

|

85

|

4-M12

|

115

|

25

|

85

|

4-φ14

|

|

25LG(R)3-10

|

11

|

130

|

1060

|

85

|

540

|

230

|

190

|

4-φ18

|

115

|

25

|

85

|

4-M12

|

115

|

25

|

85

|

4-φ14

|

|

25LG(R)3-10

|

12

|

130

|

1120

|

85

|

580

|

230

|

190

|

4-φ18

|

115

|

25

|

85

|

4-M12

|

115

|

25

|

85

|

4-φ14

|

|

25LG(R)3-10

|

13

|

130

|

1160

|

85

|

620

|

230

|

190

|

4-φ18

|

115

|

25

|

85

|

4-M12

|

115

|

25

|

85

|

4-φ14

|

|

25LG(R)3-10

|

14

|

130

|

1200

|

85

|

660

|

230

|

190

|

4-φ18

|

115

|

25

|

85

|

4-M12

|

115

|

25

|

85

|

4-φ14

|

|

25LG(R)3-10

|

15

|

130

|

1240

|

85

|

700

|

230

|

190

|

4-φ18

|

115

|

25

|

85

|

4-M12

|

115

|

25

|

85

|

4-φ14

|

|

Model |

Stages

|

L

|

H

|

H1

|

H2

|

B

|

b

|

n-φd

|

Inlet Flange

|

Outlet Flange

|

||||||

|

Dj

|

Djn

|

Dj2

|

n-dj

|

Dc

|

Dcn

|

Dc2

|

n-φdc

|

|||||||||

|

32LG(R)6.5-15

|

2

|

145

|

665

|

63

|

179

|

260

|

220

|

4-φ18

|

140

|

32

|

100

|

4-M16

|

140

|

32

|

100

|

4-φ18

|

|

32LG(R)6.5-15

|

3

|

145

|

740

|

63

|

229

|

260

|

220

|

4-φ18

|

140

|

32

|

100

|

4-M16

|

140

|

32

|

100

|

4-φ18

|

|

32LG(R)6.5-15

|

4

|

145

|

825

|

63

|

279

|

260

|

220

|

4-φ18

|

140

|

32

|

100

|

4-M16

|

140

|

32

|

100

|

4-φ18

|

|

32LG(R)6.5-15

|

5

|

145

|

895

|

63

|

329

|

260

|

220

|

4-φ18

|

140

|

32

|

100

|

4-M16

|

140

|

32

|

100

|

4-φ18

|

|

32LG(R)6.5-15

|

6

|

145

|

945

|

63

|

379

|

260

|

220

|

4-φ18

|

140

|

32

|

100

|

4-M16

|

140

|

32

|

100

|

4-φ18

|

|

32LG(R)6.5-15

|

7

|

145

|

1070

|

63

|

429

|

260

|

220

|

4-φ18

|

140

|

32

|

100

|

4-M16

|

140

|

32

|

100

|

4-φ18

|

|

32LG(R)6.5-15

|

8

|

145

|

1120

|

63

|

479

|

260

|

220

|

4-φ18

|

140

|

32

|

100

|

4-M16

|

140

|

32

|

100

|

4-φ18

|

|

32LG(R)6.5-15

|

9

|

145

|

1170

|

63

|

529

|

260

|

220

|

4-φ18

|

140

|

32

|

100

|

4-M16

|

140

|

32

|

100

|

4-φ18

|

|

32LG(R)6.5-15

|

10

|

145

|

1220

|

63

|

579

|

260

|

220

|

4-φ18

|

140

|

32

|

100

|

4-M16

|

140

|

32

|

100

|

4-φ18

|

|

40LG(R)12-15

|

2

|

145

|

710

|

70

|

193

|

260

|

220

|

4-φ18

|

150

|

40

|

110

|

4-M16

|

150

|

40

|

110

|

4-φ18

|

|

40LG(R)12-15

|

3

|

145

|

800

|

70

|

251

|

260

|

220

|

4-φ18

|

150

|

40

|

110

|

4-M16

|

150

|

40

|

110

|

4-φ18

|

|

40LG(R)12-15

|

4

|

145

|

880

|

70

|

309

|

260

|

220

|

4-φ18

|

150

|

40

|

110

|

4-M16

|

150

|

40

|

110

|

4-φ18

|

|

40LG(R)12-15

|

5

|

145

|

1015

|

70

|

367

|

260

|

220

|

4-φ18

|

150

|

40

|

110

|

4-M16

|

150

|

40

|

110

|

4-φ18

|

|

40LG(R)12-15

|

6

|

145

|

1075

|

70

|

425

|

260

|

220

|

4-φ18

|

150

|

40

|

110

|

4-M16

|

150

|

40

|

110

|

4-φ18

|

|

40LG(R)12-15

|

7

|

145

|

1170

|

70

|

483

|

260

|

220

|

4-φ18

|

150

|

40

|

110

|

4-M16

|

150

|

40

|

110

|

4-φ18

|

|

40LG(R)12-15

|

8

|

145

|

1230

|

70

|

541

|

260

|

220

|

4-φ18

|

150

|

40

|

110

|

4-M16

|

150

|

40

|

110

|

4-φ18

|

|

40LG(R)12-15

|

9

|

145

|

1410

|

70

|

599

|

260

|

220

|

4-φ18

|

150

|

40

|

110

|

4-M16

|

150

|

40

|

110

|

4-φ18

|

|

40LG(R)12-15

|

10

|

145

|

1465

|

70

|

657

|

260

|

220

|

4-φ18

|

150

|

40

|

110

|

4-M16

|

150

|

40

|

110

|

4-φ18

|

|

Model |

Stages

|

L

|

H

|

H1

|

H2

|

B

|

b

|

n-φd

|

Inlet Flange

|

Outlet Flange

|

||||||

|

Dj

|

Djn

|

Dj2

|

n-dj

|

Dc

|

Dcn

|

Dc2

|

n-φdc

|

|||||||||

|

50LG(R)24-20

|

2

|

180

|

885

|

80

|

214

|

300

|

248

|

4-φ23

|

165

|

50

|

125

|

4-M16

|

165

|

50

|

125

|

4-φ18

|

|

50LG(R)24-20

|

3

|

180

|

985

|

80

|

273

|

300

|

248

|

4-φ23

|

165

|

50

|

125

|

4-M16

|

165

|

50

|

125

|

4-φ18

|

|

50LG(R)24-20

|

4

|

180

|

1145

|

80

|

332

|

300

|

248

|

4-φ23

|

165

|

50

|

125

|

4-M16

|

165

|

50

|

125

|

4-φ18

|

|

50LG(R)24-20

|

5

|

180

|

1210

|

80

|

391

|

300

|

248

|

4-φ23

|

165

|

50

|

125

|

4-M16

|

165

|

50

|

125

|

4-φ18

|

|

50LG(R)24-20

|

6

|

180

|

1275

|

80

|

450

|

300

|

248

|

4-φ23

|

165

|

50

|

125

|

4-M16

|

165

|

50

|

125

|

4-φ18

|

|

50LG(R)24-20

|

7

|

180

|

1340

|

80

|

509

|

300

|

248

|

4-φ23

|

165

|

50

|

125

|

4-M16

|

165

|

50

|

125

|

4-φ18

|

|

50LG(R)24-20

|

8

|

180

|

1450

|

80

|

568

|

300

|

248

|

4-φ23

|

165

|

50

|

125

|

4-M16

|

165

|

50

|

125

|

4-φ18

|

|

65LG(R)36-20

|

2

|

180

|

965

|

90

|

245

|

300

|

248

|

4-φ23

|

185

|

65

|

145

|

4-M16

|

185

|

65

|

145

|

4-φ18

|

|

65LG(R)36-20

|

3

|

180

|

1120

|

90

|

304

|

300

|

248

|

4-φ23

|

185

|

65

|

145

|

4-M16

|

185

|

65

|

145

|

4-φ18

|

|

65LG(R)36-20

|

4

|

180

|

1185

|

90

|

363

|

300

|

248

|

4-φ23

|

185

|

65

|

145

|

4-M16

|

185

|

65

|

145

|

4-φ18

|

|

65LG(R)36-20

|

5

|

180

|

1295

|

90

|

422

|

300

|

248

|

4-φ23

|

185

|

65

|

145

|

4-M16

|

185

|

65

|

145

|

4-φ18

|

|

65LG(R)36-20

|

6

|

180

|

1390

|

90

|

481

|

300

|

248

|

4-φ23

|

185

|

65

|

145

|

4-M16

|

185

|

65

|

145

|

4-φ18

|

|

65LG(R)36-20

|

7

|

180

|

1455

|

90

|

540

|

300

|

248

|

4-φ23

|

185

|

65

|

145

|

4-M16

|

185

|

65

|

145

|

4-φ18

|

|

65LG(R)36-20

|

8

|

180

|

1615

|

90

|

599

|

300

|

248

|

4-φ23

|

185

|

65

|

145

|

4-M16

|

185

|

65

|

145

|

4-φ18

|

|

Model |

Stages

|

L

|

H

|

H1

|

H2

|

B

|

b

|

n-φd

|

Inlet Flange

|

Outlet Flange

|

||||||

|

Dj

|

Djn

|

Dj2

|

n-dj

|

Dc

|

Dcn

|

Dc2

|

n-φdc

|

|||||||||

|

80LG(R)50-20

|

2

|

187

|

965

|

112

|

301

|

315

|

272

|

4-φ23

|

200

|

80

|

160

|

8-M16

|

200

|

80

|

160

|

8-φ18

|

|

80LG(R)50-20

|

3

|

187

|

1195

|

112

|

379

|

315

|

272

|

4-φ23

|

200

|

80

|

160

|

8-M16

|

200

|

80

|

160

|

8-φ18

|

|

80LG(R)50-20

|

4

|

187

|

1270

|

112

|

457

|

315

|

272

|

4-φ23

|

200

|

80

|

160

|

8-M16

|

200

|

80

|

160

|

8-φ18

|

|

80LG(R)50-20

|

5

|

187

|

1395

|

112

|

535

|

315

|

272

|

4-φ23

|

200

|

80

|

160

|

8-M16

|

200

|

80

|

160

|

8-φ18

|

|

80LG(R)50-20

|

6

|

187

|

1505

|

112

|

613

|

315

|

272

|

4-φ23

|

200

|

80

|

160

|

8-M16

|

200

|

80

|

160

|

8-φ18

|

|

80LG(R)50-20

|

7

|

187

|

1675

|

112

|

691

|

315

|

272

|

4-φ23

|

200

|

80

|

160

|

8-M16

|

200

|

80

|

160

|

8-φ18

|

|

80LG(R)50-20

|

8

|

187

|

1755

|

112

|

769

|

315

|

272

|

4-φ23

|

200

|

80

|

160

|

8-M16

|

200

|

80

|

160

|

8-φ18

|

|

100LG72-20

|

2

|

187

|

1185

|

122

|

343

|

315

|

272

|

4-φ23

|

220

|

100

|

180

|

8-M16

|

220

|

100

|

180

|

8-φ18

|

|

100LG72-20

|

3

|

187

|

1270

|

122

|

432

|

315

|

272

|

4-φ23

|

220

|

100

|

180

|

8-M16

|

220

|

100

|

180

|

8-φ18

|

|

100LG72-20

|

4

|

187

|

1390

|

122

|

521

|

315

|

272

|

4-φ23

|

220

|

100

|

180

|

8-M16

|

220

|

100

|

180

|

8-φ18

|

|

100LG72-20

|

5

|

187

|

1580

|

122

|

610

|

315

|

272

|

4-φ23

|

220

|

100

|

180

|

8-M16

|

220

|

100

|

180

|

8-φ18

|

|

100LG72-20

|

6

|

187

|

1655

|

122

|

699

|

315

|

272

|

4-φ23

|

220

|

100

|

180

|

8-M16

|

220

|

100

|

180

|

8-φ18

|

|

100LG72-20

|

7

|

187

|

1800

|

122

|

788

|

315

|

272

|

4-φ23

|

220

|

100

|

180

|

8-M16

|

220

|

100

|

180

|

8-φ18

|

|

100LG72-20

|

8

|

187

|

1900

|

122

|

877

|

315

|

272

|

4-φ23

|

220

|

100

|

180

|

8-M16

|

220

|

100

|

180

|

8-φ18

|

|

100LG72-20

|

9

|

187

|

2100

|

122

|

966

|

315

|

272

|

4-φ23

|

220

|

100

|

180

|

8-M16

|

220

|

100

|

180

|

8-φ18

|

Rigid Connection

|

1

|

Ball Valve

|

2

|

Flexible Joint

|

3

|

Pressure Gauge

|

4

|

Vacuum Gauge

|

|

5

|

Gate Valve

|

6

|

Elbow Pipe

|

7

|

Pressure Measuring Pipe

|

8

|

Concrete Base

|

Flexible Connection

|

1

|

Ball Valve

|

2

|

Flexible Joint

|

3

|

Pressure Measuring Pipe

|

4

|

Gate Valve

|

5

|

Elbow Pipe

|

|

6

|

Pump

|

7

|

Connection Plate

|

8

|

JGD Vibration Isolator

|

9

|

Concrete Base

|

||

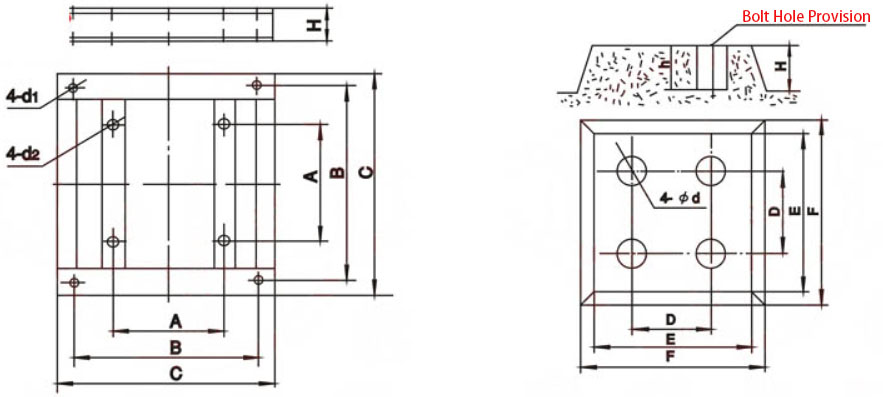

Installation Diagram(2)

Installation Dimensions(2)

|

Model

|

Connection Plate Dimensions

|

Rigid Connection Concrete Base Dimensions

|

||||||||||

|

A×A

|

B×B

|

C×C

|

H

|

d1

|

d2

|

D×D

|

E×E

|

F×F

|

H

|

d

|

h

|

|

|

25LG

|

190

|

340

|

400

|

60

|

φ14 or φ18

|

φ18

|

191

|

500

|

550

|

250

|

60

|

200

|

|

32LG

|

220

|

440

|

500

|

60

|

φ14 or φ18

|

φ18

|

219

|

500

|

550

|

250

|

60

|

200

|

|

40LG

|

220

|

440

|

500

|

60

|

φ14 or φ18

|

φ24

|

219

|

500

|

550

|

250

|

80

|

250

|

|

50LG

|

248

|

540

|

600

|

60

|

φ18 or φ22

|

φ24

|

248

|

550

|

600

|

350

|

80

|

250

|

|

65LG

|

248

|

540

|

600

|

60

|

φ18 or φ22

|

φ24

|

248

|

550

|

600

|

350

|

80

|

250

|

|

80LG

|

272

|

540

|

600

|

60

|

φ18 or φ22

|

φ24

|

272

|

600

|

650

|

350

|

80

|

250

|

|

100LG

|

272

|

540

|

600

|

60

|

φ22

|

φ24

|

272

|

600

|

650

|

350

|

80

|

250

|

OEM & Custom

Chaodun Pump provides OEM and ODM customization for LG vertical multistage pumps. Available materials: cast iron, stainless steel, bronze. Options for voltage, flange standard, outlet direction, and labeling. Suitable for distributors and project contractors worldwide.

FAQs

- What are LG pumps used for?

- LG pumps are widely used in high-rise building water supply, fire systems, and industrial circulation, providing efficient and stable water flow to meet various high-pressure demands.

- Can this pump handle hot water?

- Yes, the LG pump can handle hot water up to 105°C with the standard configuration, making it ideal for applications requiring hot water transport, such as HVAC and hot water supply systems.

- What’s the advantage of the detachable design?

- The detachable design makes maintenance more convenient, as users do not need to disassemble the piping or realign the motor. This reduces maintenance time and costs, enhancing ease of use.

- Do you offer OEM branding?

- Yes, we provide OEM services, including customized color, logo, and export packaging to meet the branding needs of different customers.

- Is the LG pump suitable for special liquids?

- Yes, the LG pump is made with corrosion-resistant materials and is suitable for handling chemical media, sewage, and other corrosive liquids, ensuring efficient operation in harsh environments.

- Can the LG pump handle corrosive liquids?

- Yes, the LG pump is designed with corrosion-resistant materials, making it ideal for pumping chemical media, sewage, and other corrosive liquids, ensuring long-term stable performance.

- How should I maintain the LG pump?

- It is recommended to regularly check the filter, replace seals, and lubricate the pump to ensure efficient operation. Regular maintenance helps extend the pump’s lifespan.

- What is the flow rate and head of the LG pump?

- The LG pump offers customized flow and head solutions to meet various application requirements, making it suitable for high-demand hydraulic systems.