Product Overview

The NL Vertical Slurry Sewage Pump is a single-stage, single-suction vertical centrifugal pump, specifically designed for handling slurry, sediment-laden liquids, and high-solid media. The pump has a compact structure and a small installation footprint. It can be started while submerged in the pumped medium, eliminating the need for priming, making it ideal for both continuous and intermittent operations in slurry and wastewater treatment applications.

The pump is equipped with a semi-open three-blade impeller, offering stable solid transfer capabilities and hydraulic efficiency. It is suitable for transferring high-viscosity liquids, sludge, and media containing solid particles.

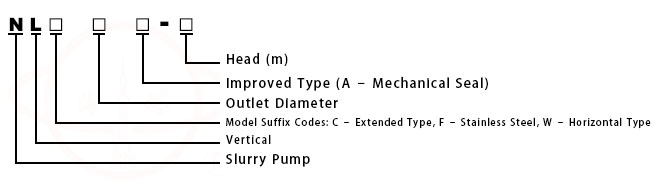

Model Designation

Key Features

-

High Solids Handling / Anti-Clogging: The semi-open three-blade impeller is designed for stable slurry and liquid transfer, even with solid particles and debris.

-

Compact Footprint / Flexible Installation: The vertical design supports both vertical or inclined installation, offering multiple overall length configurations.

-

Easy Commissioning On-Site: The pump starts after being submerged in the hydraulic end, eliminating the need for priming.

-

Wear-Resistant / Service-Friendly: The shaft sleeve and multiple oil seals reduce shaft wear and extend service life, with simple daily maintenance.

Engineering Overview

The NL Vertical Slurry Sewage Pump features an advanced hydraulic design, ensuring stable operation across the entire head range. It is particularly suitable for applications requiring high anti-clogging capability and reliable sewage discharge performance. The compact pump design is ideal for environments with limited space, accommodating various operational needs. The pump is directly coupled to the motor via a flexible coupling, ensuring smooth operation. The motor can be configured as either a single-phase or three-phase asynchronous type, depending on the application requirements.

Typical Applications

The NL Vertical Slurry Sewage Pump is widely used in:

-

Agricultural and Rural Use: River water sludge, slurry pumping, irrigation, drainage, anti-drought applications, as well as mobile firefighting, pond cleaning, and aeration in aquaculture.

-

Industrial and Municipal Services: For municipal engineering, chemical processing, dyeing, pharmaceuticals, shipbuilding, casting plants, and food processing industries, transferring slurries, flowing sands, sludge, and high-viscosity liquids.

-

Mining Applications: For transferring slurry containing mudstone and small stones in coal mines and mining areas.

-

Hydraulic Mechanized Operations: In combination with high-pressure pumps and water jet systems, used for river and pond dredging, land leveling, trench digging, and small-scale civil or hydraulic engineering.

System Configuration

The NL Vertical Slurry Sewage Pump adopts a single-stage, single-suction cantilever design. The main components include the pump casing, impeller, pump cover, bearing bracket, and shaft system. The pump casing, motor bracket, and impeller nut are made of cast iron, providing sufficient structural strength, wear resistance, and machinability. The impeller is designed to handle high solid content, ensuring smooth slurry transport and reliable hydraulic efficiency.

Components and Supply

The key components of the NL pump include the pump casing, impeller, wear plates, bearing bracket assembly, and shaft system. Materials for these components can be selected based on the specific needs of the application. The pump casing can be made from cast iron or stainless steel, while the impeller and wear parts are made from wear-resistant materials to extend the pump’s service life.

Technical Service

The NL series pumps offer comprehensive technical support services, including installation, commissioning, regular maintenance, and troubleshooting, ensuring efficient and reliable operation throughout the pump’s service life.

Operating Conditions

-

Applicable Media: Suitable for transporting thick slurries, viscous liquids, and media containing solid particles or contaminants.

-

Maximum Medium Temperature: ≤40°C.

-

Medium Density: ≤1200 kg/m³.

-

pH Range: 5–9.

-

Flow Rate Adjustment: Adjustable pump speed to meet different operational needs.

Service Conditions

Regular inspection of the pump’s sealing system, impeller, wear plates, and bearing components is required to ensure efficient and safe operation.

Protection Features

The NL series pumps are equipped with overcurrent protection, temperature monitoring, and liquid level protection systems, ensuring the pump can stop operating in abnormal conditions to prevent damage to the equipment.

Selection Standards

When selecting the pump model, consider the temperature of the medium, pH value, solid particle size, viscosity, and the required flow and head of the pump. Ensure the most suitable configuration is selected based on specific application needs.

Installation & Dimensions

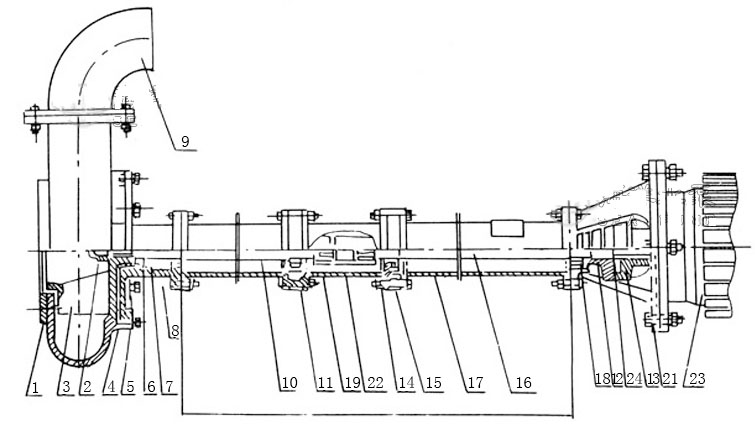

Outline Drawing

|

No.

|

Part Name / Type

|

No.

|

Part Name / Type

|

No.

|

Part Name / Type

|

|

1

|

Protective Screen

|

9

|

Discharge Elbow

|

17

|

Support Tube

|

|

2

|

Impeller Nut

|

10

|

Pump Shaft

|

18

|

Bearing Cover

|

|

3

|

Impeller

|

11

|

Bearing

|

19

|

Driven Coupling

|

|

4

|

Pump Casing

|

12

|

Driven Coupling

|

20

|

Motor Base

|

|

5

|

Pump Base

|

13

|

Driving Coupling

|

21

|

Motor Base C

|

|

6

|

O-ring

|

14

|

Connection Tube

|

22

|

Driving Coupling

|

|

7

|

Oil Seal

|

15

|

Bearing Seat

|

23

|

Motor

|

|

8

|

Shaft Sleeve

|

16

|

Connecting Shaft

|

24

|

Elastic Block

|

Performance Parameters

|

Model

|

Speed (rpm)

|

Flow Rate (m³/h)

|

Head (m)

|

Efficiency (%)

% |

Motor Power (kW)

|

Overall Height

mm |

Pump Weight (kg)

|

|

NL50-8

NL50A-8 |

1450

|

20-30

|

8-9

|

42

|

1.5

|

1310

|

63

|

|

NL50-12

NL50A-12 |

1450

|

25-38

|

12-14

|

41

|

3

|

1310

|

80

|

|

NL50-24

NL50A-24 |

1450

|

25-38

|

20-24

|

41

|

5.5

|

1430

|

152

|

|

NL65-16

NL65A-16 |

1450

|

50-60

|

15-18

|

42

|

5.5

|

1430

|

152

|

|

NL65-25

NL65A-25 |

1450

|

50-60

|

20-25

|

42

|

11

|

1510

|

265

|

|

NL76-9

NL76A-9 |

1450

|

50-70

|

9-10

|

42

|

3

|

1350

|

90

|

|

NL76-16

NL76A-16 |

1450

|

50-70

|

14-16

|

42

|

5.5

|

1430

|

152

|

|

NL76-20

NL76A-20 |

1450

|

50-70

|

18-20

|

42

|

7.5

|

1430

|

155

|

|

NL80-8

NL80A-8 |

1450

|

60-70

|

7-9

|

56

|

4

|

1400

|

120

|

|

NL80-12

NL80A-12 |

1450

|

80-120

|

11-13

|

56

|

7.5

|

1430

|

145

|

|

NL80-25

NL80A-25 |

1450

|

80-100

|

25

|

56

|

11

|

1550

|

270

|

|

NL100-7

NL100A-7 |

1450

|

70-80

|

6-8

|

61

|

4

|

1430

|

130

|

|

NL100-10

NL100A-10 |

1450

|

100

|

10

|

61

|

7.5

|

1450

|

160

|

|

NL100-16

NL100A-16 |

1450

|

80-100

|

15-17

|

61

|

15

|

1510

|

270

|

|

NL100-25

NL100A-25 |

1450

|

80-100

|

20-25

|

61

|

18.5

|

1690

|

350

|

|

NL150-12

NL150A-12 |

1450

|

100-150

|

11-13

|

66

|

18.5

|

1690

|

350

|

|

NL150-16

NL150A-16 |

1450

|

120-180

|

15-20

|

68

|

22

|

1690

|

370

|

Operating Manual

Operating Notes

-

The power supply used for the pump must be a three-phase, four-wire system. If no grounding wire is available, it must be installed to prevent electrical leakage. During operation, a circuit fuse and switch that match the motor specifications must be installed near the motor to prevent motor burnout in case the impeller becomes jammed with debris.

-

The pump can operate without any fixed foundation; it can simply be securely leaned against a firm support. If necessary, use a rope to secure it to prevent accidents. After starting, always check the motor rotation direction. Reverse rotation must not exceed one minute.

-

If the liquid being pumped contains a significant amount of debris such as weeds, iron wires, wood strips, bricks, etc., these should be removed as much as possible beforehand. A wire basket or similar device can be added to prevent debris from entering the pump, which could damage the impeller, cause jamming, or block the pipeline.

-

After pumping sludge or other contaminated media, the pump should be briefly run on clean water to flush the inside of the pump and the pipeline.

-

When working outdoors, the motor should be equipped with a protective cover to prevent rainwater or other elements from entering the motor.

-

For sludge pumping operations, the pump should be suspended on a tripod or placed on a floating pontoon or boat for mobility. During earthworks, the diameter of soil blocks broken by a high-pressure water jet should not exceed one-third of the suction inlet diameter.

-

The rated speed specified for the NL slurry pump is the maximum allowable speed and must not be arbitrarily increased. Reducing the speed is not restricted, but it will noticeably decrease efficiency.

-

When the pump is used to handle thick mud, highly viscous liquids, or for high head and long-distance slurry transport, the load conditions will decrease. However, the load should not be increased by altering the pump structure.

-

In general, after approximately 1,250 hours of operation, the pump should undergo regular maintenance. Disassemble the pump seat to check the bearings and the pump sealing conditions, clean and replace grease, and replace oil seals, shaft sleeves, and other parts as needed. For units using mechanical seals, regular maintenance should be done after approximately 3,500 hours of operation. For maintenance and parts replacement details, please refer to the installation instructions.

-

If the pump is to be out of service for an extended period, disassemble the volute casing, wipe all parts dry, apply a thin layer of oil to all sliding and mating surfaces, and store the pump in a dry location for future use.

I. Disassembly

-

Remove the motor or mounting plate and discharge pipe.

-

Remove the volute casing and impeller nut. Gently pry the impeller from the back and remove the impeller along with the key.

-

Remove the driven half coupling, then remove the key. After that, remove the motor base and separate it from the support tube.

-

Remove the bolts connecting the pump seat and support tube, and separate them.

-

Remove the shaft sleeve and bearings from the shaft.

II. Installation

-

Inspect all parts to ensure there is no damage. Apply a thin layer of grease to both sides of all paper gaskets and fill the bearings with grease to about two-thirds of their volume.

-

After filling the framework oil seals completely with grease, install them into the pump seat, then install the bearings.

-

After installing the O-ring into the shaft sleeve, coat it with grease before installing it.

-

Install the bearings into the motor base, place the paper gasket and oil deflector ring, then assemble the shaft and support tube and secure them with screws.

-

Install the paper gasket, then mount the bearing, shaft sleeve, key, pump seat, and impeller. Tighten the impeller nut, then manually rotate the impeller to ensure smooth rotation.

-

Install the paper gasket, mount the pump casing, secure it with screws, and install the strainer. Rotate the impeller by hand again to ensure it rotates smoothly.

-

Install the key and driven coupling on the pump shaft, and the key and driving coupling on the motor shaft. Then, secure the motor to the motor base with bolts. After installation, the axial clearance between the driving and driven couplings must be 1–1.5 mm.

OEM & Custom

FAQs

- Q: What is the main application of the NL/NLA vertical slurry pump?A: It is suitable for mud, sludge, slurry, and sewage in municipal, agricultural, and industrial sectors.Q: Can this pump operate without priming?

A: Yes, it starts easily as the volute is submerged in the working medium.Q: What materials are available for the pump components?

A: Standard models use cast iron; stainless or alloy versions can be customized.Q: Is OEM/ODM supported?

A: Yes, we provide full OEM services including label, structure, and motor configuration.Q: What voltage and frequency options are available?

A: 50Hz/60Hz with voltages from 220V to 460V depending on market requirements.Q: How is the pump maintained?

A: Regularly check seals, shaft sleeves, and bearings; replace lubricating oil periodically.Q: What export markets do you serve?

A: Pumps are exported to Southeast Asia, Africa, South America, and the Middle East with complete test reports and documentation.