Article Content

Pump Troubleshooting Guide: Common Faults, Causes, and Solutions

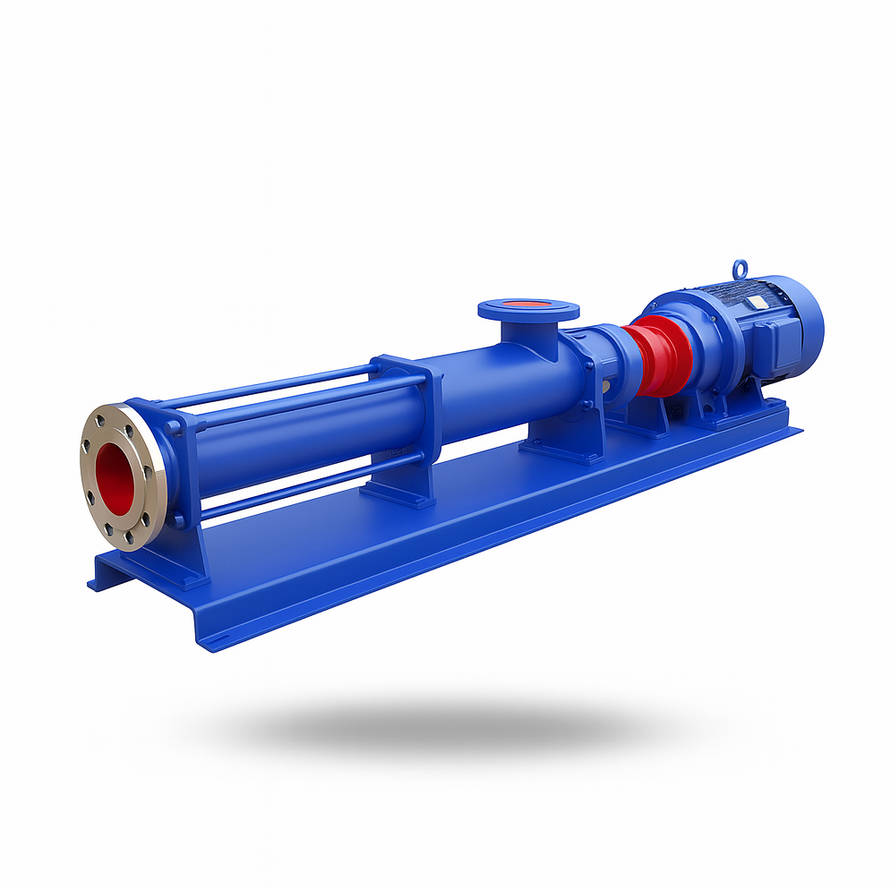

G Series Single Screw Pump for Viscous and Particle Media

This guide provides detailed troubleshooting steps for common pump operating failures. It is intended for industrial users, technicians, and maintenance professionals to diagnose faults efficiently and restore proper pump performance.

1. Pump Fails to Start

Possible causes:

- Tight fit between new rotor and stator

- Voltage or current too low

- Pumped medium viscosity too high

Recommended solutions:

- Manually rotate the pump shaft several turns using a tool to loosen internal fit

- Inspect and adjust voltage and current

- Dilute the medium to reduce viscosity

2. Pump Does Not Deliver Liquid

Possible causes:

- Incorrect rotation direction

- Issues in the suction pipeline

- High liquid viscosity

- Rotor, stator, or drive components worn or damaged

- Internal blockage within the pump

Recommended solutions:

- Correct rotation direction

- Inspect for leakage and ensure inlet/outlet valves are open

- Dilute the medium to reduce viscosity

- Inspect drive components and replace worn parts

- Remove blockages and replace damaged parts if necessary

3. Insufficient Flow Rate

Possible causes:

- Pipeline leakage

- Valves not fully opened or partially blocked

- Pump rotational speed too low

- Rotor or stator wear

Recommended solutions:

- Inspect and repair pipeline leaks

- Open all valves and remove blockages

- Adjust pump speed to rated value

- Replace worn rotor or stator components

4. Insufficient Pressure

Possible causes:

- Rotor or stator wear

Recommended solutions:

- Replace worn rotor and stator

5. Motor Overheating

Possible causes:

- Motor malfunction

- Excessive discharge pressure causing motor overload

- Stator burnt or sticking to the rotor

Recommended solutions:

- Inspect motor, voltage, current, and frequency

- Reduce discharge head, fully open discharge valve, and remove obstructions

- Replace damaged stator or related components

6. Sudden Drop in Flow or Pressure

Possible causes:

- Pipeline suddenly blocked or leaking

- Severe stator wear

- Sudden change in liquid viscosity

- Sudden voltage drop

Recommended solutions:

- Investigate each cause above and eliminate them step-by-step

7. Excessive Leakage at Shaft Seal Area

Possible causes:

- Worn soft packing

- Mechanical seal failure

Recommended solutions:

- Tighten or replace packing

- Repair or replace mechanical seal

Conclusion

Regular inspection and timely troubleshooting are essential for ensuring pump reliability. Addressing issues such as incorrect rotation, suction problems, component wear, and seal failure can greatly reduce downtime and extend service life. For unresolved or complicated faults, consult a qualified technician or pump manufacturer.