Product Overview

The PW Horizontal Cantilever Centrifugal Sewage Pump is a single-stage, single-suction, cantilever centrifugal sewage pump. The suction inlet is inclined horizontally, and the discharge outlet can be installed either horizontally or vertically as required. The main components of the pump include the pump cover, casing, impeller, shaft seal, shaft, and bearing bracket. The pump uses a double-end mechanical seal, and all fixed joints are sealed with oil-resistant “O” ring gaskets to ensure reliable static sealing. The pump and motor are mounted on a common base plate and are driven directly by the motor through a flexible coupling.

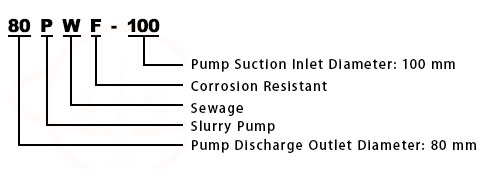

Model Meaning

Key Features

-

High Efficiency and Energy Saving: The pump is highly efficient, offering significant energy savings while providing reliable performance.

-

Low Leakage Risk: The double-end mechanical seal system effectively reduces the risk of leakage, ensuring long-term operation without issues.

-

Strong Anti-Clogging Capability: Designed to handle media with high solid content and fibers, ensuring excellent anti-clogging performance.

-

Stable Operation: Optimized hydraulic design ensures stable operation across the entire head range, suitable for various working environments.

-

Ease of Maintenance: The simple structure makes maintenance easy, with a design that allows quick disassembly, reducing downtime.

Engineering Overview

The PW series pumps feature an advanced hydraulic design to ensure stable operation across the full head range, particularly suitable for applications requiring high anti-clogging capability and reliable sewage discharge performance. The compact design of the pump makes it ideal for environments with limited space, meeting various operational needs. The pump is connected to the motor through a flexible coupling, ensuring smooth operation, with the motor available in either single-phase or three-phase asynchronous types as needed.

Typical Applications

The PW series sewage pumps are widely used in the following fields:

-

Construction Sites, Foundation Engineering, Municipal Facilities, and Hydroelectric Projects: Suitable for sewage discharge and treatment.

-

High-Rise Buildings, Civil Defense Projects, Subways, and Other Underground Facilities: Suitable for sewage discharge in basements, civil defense bunkers, subways, and other underground levels.

-

Small and Medium Enterprises’ Wastewater Treatment and Circulating Water Systems: Suitable for wastewater treatment and circulating water transport.

-

Industrial Sewage Transport: Used in food processing, papermaking, brewing, steel, textiles, and other industries for sewage transport.

System Configuration

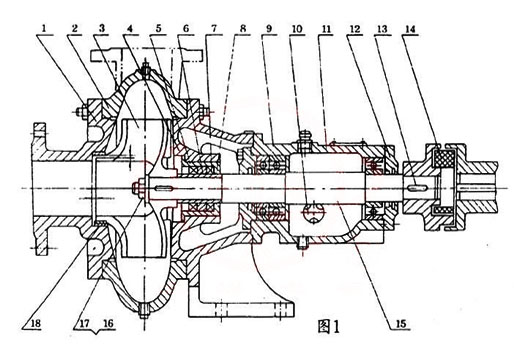

Pump Components

The PW series pump adopts a single-stage, single-suction cantilever design. The pump casing, impeller, and wear plates can be made of cast iron or stainless steel depending on specific requirements, ensuring stable operation in various working conditions. The pump is designed to be durable and corrosion-resistant, making it particularly suitable for sewage treatment and media with solid particles.

Components and Supply

The main components of the PW series pump include the pump casing, impeller, wear plates, bearing bracket assembly, etc. All key components can be customized based on customer requirements, ensuring stable operation under different working conditions. The pump casing can be made of cast iron or stainless steel based on the medium being pumped, while the impeller and wear parts are made of abrasion-resistant materials to extend the pump’s service life.

Technical Service

The PW series pumps provide full technical support services, including installation, commissioning, regular maintenance, and troubleshooting, ensuring long-term efficiency and reliability of the equipment.

Operating Conditions

-

Applicable Media: Suitable for pumping sewage containing solid particles and other non-corrosive media.

-

Maximum Medium Temperature: ≤40°C.

-

pH Range: 5–9.

-

Flow Adjustment: The pump speed can be adjusted to meet different operational requirements.

Service Conditions

Regular inspection of the pump’s sealing system, impeller, wear plates, and bearing components is required to ensure the pump operates efficiently and safely, extending the pump’s service life.

Protection Features

The PW series pumps are equipped with overcurrent protection, temperature monitoring, and liquid level protection systems, ensuring that the pump can stop operating in abnormal conditions to prevent equipment damage.

Selection Standards

When selecting the pump model, consider factors such as the temperature of the media, viscosity, solid particle size, pH value, and the required flow and head of the pump. Ensure the selection of the most suitable configuration based on specific application needs.

Installation & Dimensions

Outline Drawing

Performance Data

|

No.

|

Name

|

No.

|

Name

|

|

1

|

Pump Cover

|

10

|

Oil Indicator

|

|

2

|

Pump Body

|

11

|

Bearing Housing

|

|

3

|

Impeller

|

12

|

Bearing Cover

|

|

4

|

Seal Body

|

13

|

Flat Key

|

|

5

|

Seal Box

|

14

|

Elastic Ring

|

|

6

|

Washer

|

15

|

Shaft

|

|

7

|

Shaft Sleeve (Not used in 4PW)

|

16

|

Nut

|

|

8

|

Oil Seal

|

17

|

Gasket

|

|

9

|

Bearing

|

18

|

Seal Ring

|

Performance Parameters

|

Item No.

|

Model

|

Flow Rate (m³/h)

|

Head (m)

|

Speed (rpm)

|

Power (kW)

|

||

|

m3/h

|

L/s

|

m

|

r/min

|

Shaft Power

|

Power (kW)

|

||

|

1

|

50PW-65

50PWF-65 |

14.5

|

4

|

16

|

1440

|

2.47

|

4

|

|

2

|

50PW-65

50PWF-65 |

25

|

6.94

|

32

|

2900

|

3.35

|

4

|

|

3

|

80PW-100

80PWF-100 |

56

|

15.5

|

13.5

|

1440

|

4.1

|

5.5

|

|

4

|

80PW-100

80PWF-100 |

90

|

25

|

26

|

2900

|

7

|

11

|

|

5

|

100PW-125

100PWF-125 |

100

|

27.8

|

12.5

|

1440

|

5.7

|

7.5

|

|

6

|

21/2PW

|

60

|

16.6

|

9.5

|

1440

|

2.5

|

4

|

|

7

|

21/2PW

|

90

|

25

|

26

|

2920

|

11

|

15

|

|

8

|

21/2PW

|

90

|

25

|

43

|

2940

|

17

|

22

|

|

9

|

4PW

|

100

|

27.8

|

11

|

960

|

4.7

|

7.5

|

|

10

|

4PW

|

160

|

44.4

|

25.5

|

1460

|

18

|

30

|

|

11

|

6PW

|

300

|

83.3

|

14

|

980

|

17

|

30

|

|

12

|

6PW

|

350

|

97

|

27

|

1450

|

42

|

55

|

|

13

|

8PW

|

500

|

139

|

13

|

730

|

29

|

45

|

|

14

|

8PW

|

550

|

153

|

25

|

980

|

59.5

|

75

|

|

15

|

10PW

|

800

|

222

|

13.5

|

730

|

40.2

|

75

|

|

16

|

10PW

|

1000

|

278

|

25

|

980

|

92

|

132

|

Operating Manual

-

Installation:

-

(a) Clean the base from oil and dirt before placing it on the foundation.

-

(b) Check the level of the base using a spirit level, and use wedges for adjustment if necessary (for an assembled unit, use the pump’s discharge flange plane to check the level).

-

(c) Pour cement into the anchor bolt holes.

-

(d) After the cement has cured, check if the anchor bolts are loose, tighten them if necessary, and recheck the level.

-

(e) Clean the support surfaces of the base, pump feet, and motor feet, then install the pump and motor onto the base.

-

(f) Ensure an appropriate gap between the couplings, and check that the pump shaft and motor shaft are aligned. If misalignment is detected, adjust with shims to make them concentric. The radial deviation between the outer circles of the coupling should not exceed 0.1 mm, and the gap between the two coupling faces should not exceed 0.3 mm.

-

-

Notes:

-

The suction and discharge pipes should be supported independently and not bear the weight of the pump.

-

Install a gate valve on the discharge pipe.

-

A general-purpose strainer should be installed at the suction pipe inlet to prevent larger objects like stones from entering and damaging the impeller.

-

-

Startup:

-

Check that the bearing housing is filled with lubricating oil and that the oil level is correct.

-

Verify the motor’s rotation direction matches the pump’s rotation direction.

-

Close the discharge valve and pressure gauge cock, then fill the suction pipe with water through the pump’s upper hole.

-

Start the motor and open the pressure gauge cock.

-

Once the pump reaches its normal speed and the pressure gauge shows the appropriate reading, open the vacuum gauge cock and gradually open the discharge valve to the required position.

-

-

Stop:

-

Gradually close the discharge valve and then cut off the power.

-

In freezing conditions, open the drain valve at the pump’s bottom to empty the liquid and prevent freezing damage.

-

For long periods of inactivity, disassemble the parts, clean them, apply anti-rust oil to the sliding surfaces, and store the pump properly.

-

-

Operation:

-

During operation, monitor the instruments, bearing temperature, packing leakage, and vibration. If any abnormalities are found, address them immediately.

-

Bearing temperature should not exceed 75°C.

-

Keep the bearing oil at the normal oil level. If the oil is too low, add oil promptly.

-

If the gap between the sealing ring and the impeller exceeds the specified value, replace the sealing ring.

-

For a suction inlet diameter ≤100 mm, the total gap in the radial direction should be ≥1.5 mm;

-

For a suction inlet diameter >100 mm, the total gap should be ≥2 mm.

-

-

OEM & Custom

FAQs

- Q: What’s the difference between PW and PWF?

- A: PW is standard cast-iron sewage service; PWF uses stainless steel for acidic/alkaline or corrosive wastewater up to 80 °C.

- Q: Can the discharge be vertical or horizontal?

A: Yes. The outlet can be oriented vertically or horizontally to suit site piping. - Q: What seal type is used?

A: A double-face mechanical seal with auxiliary oil seal structure for reliable sealing and easy replacement. - Q: How do you align the unit during installation?

A: Level the base, grout anchors, and align couplings with TIR ≤ 0.1 mm and end-gap deviation ≤ 0.3 mm. - Q: Which industries commonly use PWF?

A: Chemical, petroleum, food, pharmaceutical, and environmental plants handling corrosive wastewater. - Q: Do you provide explosion-proof motors and special voltages?

A: Yes. Explosion-proof and special motors/voltages are available upon request. - Q: What information is needed for quotation?

A: Medium type, SG, temperature, viscosity, required flow/head, voltage/frequency, and discharge orientation.