Product Overview

The QDX(T)/QX(T) submersible pump is a compact self-priming centrifugal pump consisting of three main components: the pump hydraulic section, sealing system, and motor. This unit features an integrated protection design, ensuring continuous operation under specific submersible conditions.

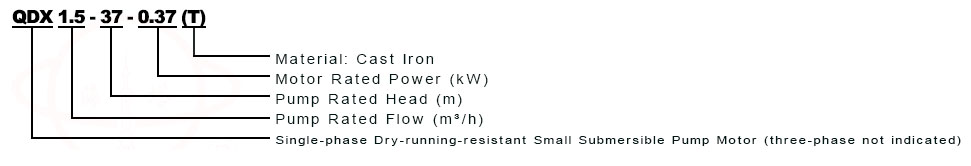

Model Designation

Key Features

-

Self-Priming Design: No foot valve is required; simply maintain a certain amount of start-up liquid in the pump body before starting, simplifying the pipeline system and improving operational conditions.

-

Compact Structure: Simple, efficient design with minimal space requirements, ideal for confined spaces.

-

Efficient Gas-Liquid Separation: High-efficiency gas-liquid separation and circulation structure ensures stable suction performance.

-

Dual Mechanical Seals: Equipped with dual mechanical seals for enhanced sealing reliability, reducing leakage risks.

-

Multi-Functionality: Suitable for low-head, small-flow, continuous submersible operation and complex suction conditions.

Engineering Overview

The QDX(T)/QX(T) submersible pump features an upper-mounted motor and lower-mounted hydraulic section design, offering high performance and stability. The motor can be a single-phase or three-phase asynchronous motor, while the pump section uses a centrifugal impeller, with a vertical discharge casing to ensure hydraulic performance stability. With precise hydraulic design, this series of pumps offers a wide range of operating conditions, especially suitable for frequent start-stop cycles.

Typical Applications

-

Municipal & Environmental: Widely used in municipal drainage, wastewater treatment, and river dredging.

-

Construction & Fire Systems: Providing stable water sources for high-rise buildings, residential complexes, and landscape irrigation.

-

Industrial & Mining: Applied in industrial cooling, mine drainage, etc.

-

Agricultural Irrigation: Suitable for agricultural irrigation, especially sprinkler systems.

-

Filter Press Systems: Used in slurry transport and feeding in filter press systems.

Suitable for clean water, seawater, mildly acidic or alkaline liquids, and general slurry media.

System Configuration

The pump consists of the pump casing, impeller, connecting body, sliding bearings, stator, rotor, canned cover, motor housing, and related components. The stator and rotor are separated by an independent can; the bearings are made of graphite-impregnated resin composite materials. The suction medium also serves as a lubricant and cooling liquid. The pump adopts a vertical single-stage, single-suction centrifugal design, with the inlet and outlet on the same horizontal axis, making it easy to install directly in the pipeline.

Components & Supply

-

Motor Assembly: Single-phase or three-phase asynchronous motor.

-

Pump Assembly: Centrifugal impeller, rotor, balance disc.

-

Sealing System: Dual mechanical seals with oil-resistant rubber O-rings.

-

Bearing Assembly: Sliding bearings with lubrication oil.

-

Cooling System: Available on some models, equipped with a cooling system for temperature control.

Technical Service

The series of pumps are easy to install and maintain. Maintenance is simplified, as the entire rotor assembly can be removed for inspection or repairs by loosening the connecting body nuts, without disassembling the pipeline system. Due to its low noise and vibration characteristics, vibration isolators or pads are generally not needed.

Operating Conditions

-

Medium: Clean water, seawater, mildly acidic or alkaline liquids, and general slurry (viscosity ≤100 cP, solid content ≤30%).

-

Operating Temperature: Standard model ≤80°C; hot water type ≤160°C.

-

System Working Pressure: ≤1.2 MPa, with inlet pressure ≥0.5 MPa. Confirm special operating conditions with the manufacturer.

-

Environmental Conditions: Ambient temperature ≤40°C, relative humidity ≤95%.

Service Conditions

-

Medium: Clean water or similar liquids.

-

Solid Content: Maximum particle size ≤2mm, volume content ≤1%.

-

Bearing Lubrication: Lubricated with calcium-based grease.

Protection Function

-

Self-Priming Capability: Ensured by an optimized gas-liquid separation process, providing reliable self-priming performance.

-

Temperature Monitoring: An optional external cooling system maintains bearing temperatures within safe limits.

Selection Criteria

-

Choose the pump model based on actual application requirements, including medium type, flow, operating pressure, and temperature conditions.

-

Select the appropriate sealing type and cooling system to ensure long-term stable operation of the pump.

Performance Parameters

|

No.

|

Model / Specification

|

Flow Rate (m3/h)

|

Head (m)

|

Power (kW)

|

Voltage (V)

|

Current (A)

|

Speed (r/min)

|

Dimensions (mm)

|

Pipe I.D. (mm)

|

Head Range (m)

|

|

1

|

QDX1.5-17-0.37(T)

|

1.5

|

17

|

0.37

|

220

|

2.87

|

3000

|

345×195

|

25

|

4-19

|

|

2

|

QDX1.5-25-0.55(T)

|

1.5

|

2

|

0.55

|

220

|

4.07

|

3000

|

340×220

|

25

|

17-26

|

|

3

|

QDX3-18-0.55(T)

|

3

|

18

|

0.55

|

220

|

4.07

|

3000

|

340×210

|

32

|

5-21

|

|

4

|

QDX10-12-0.55(T)

|

10

|

12

|

0.55

|

220

|

4.07

|

3000

|

340×220

|

38

|

7-15

|

|

5

|

QDX1.5-32-0.75(T)

|

1.5

|

32

|

0.75

|

220

|

5.24

|

3000

|

365×240

|

25

|

17-32

|

|

6

|

QDX3-24-0.75(T)

|

3

|

24

|

0.75

|

220

|

5.24

|

3000

|

365×220

|

32

|

14-26

|

|

7

|

QDX8-18-0.75(T)

|

8

|

18

|

0.75

|

220

|

5.24

|

3000

|

365×220

|

38

|

15-19

|

|

8

|

QDX10-16-0.75(T)

|

10

|

16

|

0.75

|

220

|

5.24

|

3000

|

365×220

|

51

|

10-19

|

|

9

|

QDX15-10-0.75(T)

|

15

|

10

|

0.75

|

220

|

5.24

|

3000

|

385×240

|

64

|

3-11

|

|

10

|

QDX6-25-1.1*

|

6

|

25

|

1.1

|

220

|

7.02

|

3000

|

410×365

|

61

|

13-26

|

|

11

|

QX8-18-0.75(T)

|

8

|

18

|

0.75

|

380

|

1.99

|

3000

|

365×220

|

38

|

15-19

|

|

12

|

QX6-25-1.1*

|

6

|

25

|

1.1

|

380

|

2.74

|

3000

|

410×265

|

51

|

13-26

|

|

13

|

QX10-34-2.2*

|

10

|

34

|

2.2

|

380

|

5.11

|

3000

|

495×295

|

51

|

18-36

|

|

14

|

QX10-34-2.2(T)

|

10

|

34

|

2.2

|

380

|

5.11

|

3000

|

485×280

|

51

|

18-36

|

|

15

|

QX12.5-50-4*

|

12.5

|

50

|

4

|

380

|

8.8

|

3000

|

585×300

|

51

|

35-53

|

|

16

|

QX12.5-60-5.5*

|

12.5

|

60

|

5.5

|

380

|

11.7

|

3000

|

630×300

|

51

|

50-61

|

OEM & Custom

We provide OEM/ODM services for voltage (220V/380V/415V), material customization (stainless steel 304/316), and cable length adjustment. Explosion-proof configurations and automatic control options are available. All pumps comply with ISO9001 and CE export standards for international markets.

FAQs

- Q: What’s the main use of QDX(T)/QX(T) pumps?

A: They are mainly used for clean water lifting in wells, gardens, irrigation, and households. - Q: Are they suitable for continuous operation?

A: Yes, under proper cooling and immersion conditions, they can operate continuously. - Q: What’s the maximum depth of use?

A: Up to 5 meters immersion depth. - Q: Can they handle dirty water?

A: No, only for clean water or liquids with solid particles ≤0.2 mm. - Q: Do you support OEM branding?

A: Yes, private labeling and packaging customization are supported. - Q: What’s the motor type?

A: Single-phase (220V) or three-phase (380V) asynchronous motors with built-in protection. - Q: Which countries use these pumps?

A: Widely exported to Southeast Asia, Africa, and South America for agricultural and domestic applications.