Product Overview

The QW/WQ Series Non-Clogging Submersible Sewage Pump is designed for high solid content and fibrous media. With an optimized hydraulic design, it integrates high-efficiency pumping, anti-clogging capabilities, and reliable operation into a compact structure. The pump features a single-channel or double-channel impeller, allowing it to efficiently handle solid particles and long fiber materials. It is suitable for municipal sewage treatment, industrial wastewater discharge, and agricultural irrigation applications.

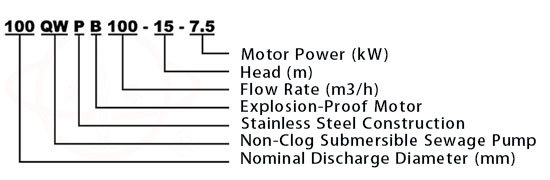

Model Designation

Key Features

-

Single-channel or double-channel impeller design, improving the ability to handle solid particles and long fibers, reducing the risk of clogging.

-

Mechanical seals with abrasion-resistant hard alloy friction pairs, ensuring long-term continuous operation and reliable sealing performance.

-

Compact structure with low noise, small footprint, easy maintenance, and convenient component replacement.

-

Optional automatic control system for start/stop operations based on liquid level changes, reducing manual intervention.

-

Multiple installation options available, allowing installation and maintenance without entering the sewage pit.

-

Operates safely within the design performance range, ensuring the motor is not overloaded.

Engineering Summary

The QW/WQ Series Non-Clogging Submersible Sewage Pump adopts an optimized hydraulic design, with a single or double-channel impeller and high-efficiency cutting system, ensuring reliable handling of wastewater with solid particles and long fibers. The pump’s hydraulic components, including the impeller and casing, have been designed for durability, and the pump performs well in a wide range of applications. It is ideal for industrial, municipal, and construction drainage systems, offering long-term reliability and low maintenance.

Typical Applications

The QW/WQ Series Non-Clogging Submersible Sewage Pump is suitable for:

-

Industrial and commercial wastewater discharge systems

-

Residential sewage lifting stations

-

Municipal sewage treatment plant discharge systems

-

Civil defense and emergency drainage systems

-

Sewage discharge in hospitals, hotels, and public buildings

-

Municipal engineering and construction site drainage

-

Auxiliary dewatering in mining operations

-

Rural biogas pits and agricultural irrigation

It is designed for pumping sewage, wastewater with solid particles, sludge, wood chips, starch, minerals, and other suspended solids, as well as clean water or mildly corrosive liquids.

System & Operation

Components & Supply

-

Single or double-channel impeller design, improving the ability to handle solid particles and long fibers.

-

High abrasion-resistance mechanical seals with hard alloy friction pairs, ensuring long-lasting and reliable sealing performance.

-

Compact structure with low noise, small footprint, and easy maintenance, facilitating quick component replacement.

-

Optional fully automatic control panel for start/stop operation based on liquid level changes, reducing the need for manual intervention.

Technical Specifications

Operating Conditions

-

Liquid Temperature:

• Standard Pump: ≤ 40°C

• Hot Water Pump: ≤ 80°C (special applications can meet up to 120°C) -

Ambient Temperature: ≤ +40°C

-

Maximum Working Pressure: 10 bar

-

Maximum Allowable Inlet Pressure: Limited by system working pressure

-

Fluid Requirements:

• Clean, low-viscosity, non-flammable, sulfur-free liquids, free from solid particles or fibers

• Suitable for pumping mineral water, softened water, purified water, light oils, and mild chemical fluids

• If the liquid’s density or viscosity exceeds that of water, a higher-rated motor should be selected

• The pump’s suitability for specific liquids depends on factors such as chloride content, pH, temperature, and solvent/oil content

Service Conditions

-

Installation Altitude: Must not exceed 1000 meters; for higher elevation applications, specify at the time of order for proper configuration.

-

The pump must not be used in flammable or explosive environments, nor should it handle combustible liquids.

-

Installation should be in a well-ventilated, dry, and vibration-free location.

-

Maximum ambient temperature should not exceed +40°C.

Protection Functions

-

The motor should be equipped with overload protection, phase failure protection, and overheat protection devices to prevent damage under abnormal conditions.

-

Dry-run protection is recommended to prevent mechanical seal failure in case of insufficient water supply.

-

Pressure switches or variable frequency drives (VFDs) should be used to maintain safe pressure ranges.

-

Check valves and anti-backflow devices must be installed to prevent damage caused by reverse flow after shutdown.

Selection Criteria

-

Select the pump model and number of stages based on required flow rate and head.

-

Choose appropriate wetted materials (e.g., SS304, SS316L) based on fluid temperature, pH, and chloride content.

-

Select sealing structure (mechanical seal or packing seal) based on the fluid’s corrosive properties.

-

Ensure installation space and piping layout compatibility with the horizontal configuration.

-

If the pumped liquid has higher viscosity or density than water, a higher-rated motor should be selected to meet the required shaft power.

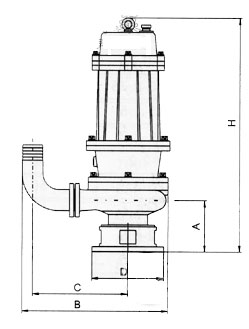

Installation & Dimensions

Outline Drawing

Performance Data

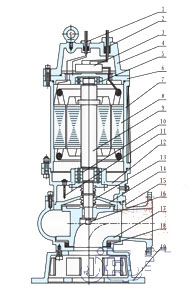

|

Serial No.

|

Name

|

Serial No.

|

Name

|

Serial No.

|

Name

|

Serial No.

|

Name

|

|

1

|

Shaft sleeve

|

6

|

Upper shaft seat

|

11

|

Oil-water probe

|

16

|

Impeller bolt

|

|

2

|

Motor wiring

|

7

|

Motor casing

|

12

|

Oil chamber

|

17

|

Impeller

|

|

3

|

Terminal box

|

8

|

Stator

|

13

|

Mechanical seal

|

18

|

Seal ring

|

|

4

|

Motor cover

|

9

|

Shaft (rotor)

|

14

|

Rear cover plate

|

19

|

Chassis

|

|

5

|

Bearing

|

10

|

Bearing

|

15

|

Pump body

|

Installation Diagram

Performance Parameters

|

Item No.

|

Diameter

|

Flow Rate

|

Head

|

Speed

|

Power

|

Efficiency

|

A

|

B

|

C

|

D

|

H

|

Auto-Coupling Device

|

|

mm

|

(m3/h)

|

(M)

|

(r/min)

|

(kw)

|

(%)

|

|||||||

|

25-7-8-0.55

|

25

|

7

|

8

|

2900

|

0.55

|

45

|

120

|

360

|

225

|

210

|

540

|

|

|

25-8-22-1.1

|

25

|

8

|

22

|

2900

|

1.1

|

45

|

120

|

360

|

225

|

210

|

540

|

|

|

32-8-12-0.75

|

32

|

8

|

12

|

2900

|

0.75

|

48

|

120

|

360

|

225

|

210

|

540

|

|

|

32-12-15-1.1

|

32

|

12

|

15

|

2900

|

1.1

|

45

|

120

|

360

|

225

|

210

|

540

|

|

|

40-15-15-1.5

|

40

|

15

|

15

|

2900

|

1.5

|

48

|

120

|

360

|

225

|

210

|

540

|

|

|

40-15-30-2.2

|

40

|

15

|

30

|

2900

|

2.2

|

54

|

120

|

360

|

225

|

210

|

540

|

|

|

50-20-7-0.75

|

50

|

20

|

7

|

2900

|

0.75

|

51

|

145

|

440

|

275

|

185

|

520

|

GAK-50

|

|

50-10-10-0.75

|

50

|

10

|

10

|

2900

|

0.75

|

52

|

120

|

250

|

230

|

185

|

520

|

GAK-50

|

|

50-20-15-1.5

|

50

|

20

|

15

|

290

|

1.5

|

53

|

120

|

250

|

230

|

210

|

564

|

GAK-50

|

|

50-15-25-2.2

|

50

|

15

|

25

|

2900

|

2.2

|

54

|

145

|

410

|

245

|

205

|

550

|

GAK-50

|

|

50-18-30-3

|

50

|

18

|

30

|

2900

|

3

|

55

|

155

|

420

|

250

|

260

|

660

|

GAK-50

|

|

50-40-15-4

|

50

|

40

|

15

|

2900

|

4

|

55

|

140

|

457

|

264

|

310

|

730

|

GAK-50

|

|

50-25-32-5.5

|

50

|

25

|

32

|

2900

|

5.5

|

55

|

165

|

480

|

285

|

310

|

770

|

GAK-50

|

|

50-20-40-7.5

|

50

|

50

|

20

|

2900

|

7.5

|

58

|

175

|

480

|

285

|

310

|

770

|

GAK-50

|

|

65-25-15-2.2

|

65

|

25

|

15

|

2900

|

2.2

|

50

|

145

|

450

|

280

|

205

|

570

|

GAK-65

|

|

65-37-13-3

|

65

|

37

|

13

|

2900

|

3

|

57

|

165

|

475

|

305

|

260

|

652

|

GAK-65

|

|

65-25-30-4

|

65

|

25

|

30

|

2900

|

4

|

61

|

170

|

505

|

300

|

325

|

710

|

GAK-65

|

|

65-30-40-7.5

|

65

|

30

|

40

|

2900

|

7.5

|

56

|

GAK-65

|

|||||

|

65-35-50-11

|

65

|

35

|

50

|

2900

|

11

|

45

|

165

|

460

|

300

|

350

|

920

|

GAK-65

|

|

65-35-60-15

|

65

|

35

|

60

|

2900

|

15

|

65

|

165

|

460

|

300

|

350

|

920

|

GAK-65

|

|

80-40-7-2.2

|

80

|

40

|

7

|

1450

|

2.2

|

59

|

165

|

510

|

330

|

260

|

640

|

GAK-80

|

|

80-43-13-3

|

80

|

43

|

13

|

2900

|

3

|

70

|

165

|

540

|

330

|

325

|

652

|

GAK-80

|

|

80-40-15-4

|

80

|

40

|

15

|

2900

|

4

|

61

|

180

|

565

|

330

|

325

|

775

|

GAK-80

|

|

80-60-13-5.5

|

80

|

60

|

13

|

2900

|

5.5

|

67

|

165

|

565

|

330

|

325

|

775

|

GAK-80

|

|

80-65-25-7.5

|

80

|

65

|

25

|

2900

|

7.5

|

63

|

180

|

656

|

330

|

325

|

775

|

GAK-80

|

|

Item No.

|

Diameter

|

Flow Rate

|

Head

|

Speed

|

Power

|

Efficiency

|

A

|

B

|

C

|

D

|

H

|

Auto-Coupling Device

|

|

mm

|

(m3/h)

|

(M)

|

(r/min)

|

(kw)

|

(%)

|

|||||||

|

100-80-10-4

|

100

|

100

|

10

|

1450

|

4

|

65

|

220

|

700

|

430

|

420

|

800

|

GAK-100

|

|

100-100-15-7.5

|

100

|

100

|

15

|

1450

|

7.5

|

68

|

225

|

690

|

420

|

420

|

825

|

GAK-100

|

|

100-80-20-7.5

|

100

|

80

|

20

|

1450

|

7.5

|

65

|

225

|

690

|

420

|

420

|

825

|

GAK-100

|

|

100-100-25-11

|

100

|

100

|

25

|

1450

|

11

|

70

|

225

|

690

|

450

|

520

|

940

|

GAK-100

|

|

100-100-30-15

|

100

|

100

|

30

|

1450

|

15

|

65

|

GAK-100

|

|||||

|

100-100-35-18.5

|

100

|

100

|

35

|

1450

|

18.5

|

68

|

225

|

680

|

410

|

420

|

970

|

GAK-100

|

|

125-130-15-11

|

125

|

130

|

15

|

1450

|

11

|

72

|

GAK-125

|

|||||

|

125-130-20-15

|

125

|

130

|

20

|

1450

|

15

|

75

|

GAK-125

|

|||||

|

150-145-9-7.5

|

150

|

145

|

9

|

1450

|

7.5

|

76

|

225

|

800

|

510

|

420

|

795

|

GAK-150

|

|

150-180-15-15

|

150

|

180

|

15

|

1450

|

15

|

69

|

275

|

950

|

610

|

520

|

1060

|

GAK-150

|

|

150-180-20-18.5

|

150

|

180

|

20

|

1450

|

18.5

|

72

|

250

|

925

|

858

|

520

|

1060

|

GAK-150

|

|

150-180-25-22

|

150

|

180

|

25

|

1450

|

22

|

78

|

260

|

925

|

585

|

520

|

1060

|

GAK-150

|

|

150-130-30-22

|

150

|

130

|

30

|

1450

|

22

|

78

|

260

|

925

|

585

|

520

|

1060

|

GAK-150

|

|

150-180-30-30

|

150

|

180

|

30

|

1450

|

30

|

78

|

GAK-150

|

|||||

|

150-200-30-37

|

150

|

200

|

30

|

1450

|

37

|

73

|

275

|

1025

|

650

|

520

|

1320

|

GAK-150

|

|

200-300-7-11

|

200

|

300

|

7

|

980

|

11

|

66

|

290

|

990

|

610

|

520

|

1150

|

GAK-200

|

|

200-250-11-15

|

200

|

250

|

11

|

1450

|

15

|

64

|

270

|

970

|

600

|

520

|

1120

|

GAK-200

|

|

200-250-15-18.5

|

200

|

250

|

15

|

1450

|

18.5

|

73

|

290

|

1130

|

715

|

520

|

1130

|

GAK-200

|

|

200-400-10-22

|

200

|

400

|

10

|

1450

|

22

|

75

|

275

|

1120

|

710

|

520

|

1130

|

GAK-200

|

|

200-400-13-30

|

200

|

400

|

13

|

14501

|

30

|

76

|

275

|

1120

|

710

|

520

|

1320

|

GAK-200

|

|

200-300-15-22

|

200

|

300

|

15

|

1450

|

22

|

76

|

275

|

1120

|

710

|

520

|

1130

|

GAK-200

|

|

200-250-22-30

|

200

|

250

|

22

|

1450

|

30

|

71

|

275

|

1120

|

710

|

520

|

1290

|

GAK-200

|

|

200-350-25-37

|

200

|

350

|

25

|

1450

|

37

|

71

|

325

|

1080

|

680

|

520

|

1370

|

GAK-200

|

|

200-400-30-45

|

200

|

400

|

30

|

1450

|

45

|

74

|

330

|

1250

|

780

|

520

|

1370

|

GAK-200

|

|

Item No.

|

Diameter

|

Flow Rate

|

Head

|

Speed

|

Power

|

Efficiency

|

A

|

B

|

C

|

D

|

H

|

Auto-Coupling Device

|

|

mm

|

(m3/h)

|

(M)

|

(r/min)

|

(kw)

|

(%)

|

|||||||

|

250-600-9-30

|

250

|

600

|

9

|

980

|

30

|

78

|

440

|

1100

|

700

|

520

|

1660

|

GAK-250

|

|

250-600-12-37

|

250

|

600

|

12

|

1450

|

37

|

76

|

440

|

1100

|

700

|

520

|

1660

|

GAK-250

|

|

250-600-15-45

|

250

|

600

|

15

|

1450

|

45

|

73

|

440

|

1100

|

700

|

520

|

1660

|

GAK-250

|

|

250-600-20-55

|

250

|

600

|

20

|

1450

|

55

|

73

|

440

|

1100

|

700

|

520

|

1700

|

GAK-250

|

|

250-600-25-75

|

250

|

600

|

25

|

1450

|

75

|

71

|

440

|

1100

|

700

|

520

|

1750

|

GAK-250

|

|

300-800-12-45

|

300

|

800

|

12

|

980

|

45

|

74

|

470

|

1305

|

850

|

650

|

1845

|

GAK-300

|

|

300-480-15-45

|

300

|

480

|

15

|

1450

|

45

|

66

|

470

|

1305

|

850

|

650

|

1845

|

GAK-300

|

|

300-800-15-55

|

300

|

800

|

15

|

1450

|

55

|

73

|

470

|

1305

|

850

|

650

|

2060

|

GAK-300

|

|

300-600-20-55

|

300

|

600

|

20

|

1450

|

55

|

73

|

470

|

1305

|

850

|

650

|

2060

|

GAK-300

|

|

300-800-20-75

|

300

|

800

|

20

|

1450

|

75

|

75

|

470

|

1305

|

850

|

650

|

2120

|

GAK-300

|

|

300-950-20-90

|

300

|

950

|

20

|

1450

|

90

|

76

|

470

|

1305

|

850

|

650

|

2120

|

GAK-300

|

|

300-1000-25-110

|

300

|

1000

|

25

|

1450

|

110

|

76

|

500

|

1350

|

875

|

650

|

2220

|

GAK-300

|

|

300-1100-10-55

|

300

|

1100

|

10

|

1450

|

55

|

73

|

GAK-300

|

|||||

|

350-1500-15-90

|

350

|

1500

|

15

|

740

|

90

|

87

|

630

|

1533

|

1280

|

700

|

2190

|

GAK-350

|

|

350-1200-18-90

|

350

|

1200

|

18

|

980

|

90

|

85

|

500

|

900

|

500

|

750

|

2190

|

GAK-350

|

|

350-1100-28-132

|

350

|

1100

|

28

|

980

|

132

|

84

|

700

|

1616

|

1363

|

700

|

2480

|

GAK-350

|

|

350-1000-36-160

|

350

|

1000

|

36

|

980

|

160

|

84

|

700

|

1666

|

1413

|

700

|

2590

|

GAK-350

|

|

400-1760-7.5-55

|

400

|

1760

|

7.5

|

980

|

55

|

83

|

GAK-400

|

|||||

|

400-1500-10-75

|

400

|

1500

|

10

|

980

|

75

|

86

|

600

|

1650

|

1365

|

780

|

2000

|

GAK-400

|

|

400-2000-13-110

|

400

|

2000

|

13

|

980

|

110

|

84

|

600

|

1650

|

1365

|

780

|

2280

|

GAK-400

|

|

400-2000-15-132

|

400

|

2000

|

15

|

980

|

132

|

83

|

GAK-400

|

|||||

|

400-1700-22-160

|

400

|

1700

|

22

|

980

|

160

|

83

|

630

|

1670

|

1380

|

780

|

2600

|

GAK-400

|

|

400-1500-26-160

|

400

|

1500

|

26

|

980

|

160

|

84

|

630

|

1670

|

1380

|

780

|

2600

|

GAK-400

|

|

Item No.

|

Diameter

|

Flow Rate

|

Head

|

Speed

|

Power

|

Efficiency

|

A

|

B

|

C

|

D

|

H

|

Auto-Coupling Device

|

|

mm

|

(m3/h)

|

(M)

|

(r/min)

|

(kw)

|

(%)

|

|||||||

|

400-1800-32-250

|

400

|

1800

|

32

|

980

|

250

|

82

|

670

|

1730

|

1440

|

780

|

2850

|

GAK-400

|

|

500-2500-10-110

|

500

|

2500

|

10

|

740

|

110

|

85

|

900

|

2218

|

1875

|

900

|

2250

|

GAK-500

|

|

500-2600-15-160

|

500

|

2600

|

15

|

740

|

160

|

84

|

955

|

1968

|

1625

|

900

|

2450

|

GAK-500

|

|

500-2400-22-220

|

500

|

2400

|

22

|

740

|

220

|

85

|

900

|

2218

|

1875

|

900

|

2520

|

GAK-500

|

|

500-2650-24-250

|

500

|

2650

|

24

|

740

|

250

|

85

|

1017

|

2198

|

2395

|

900

|

3000

|

GAK-500

|

Operating Manual

Usage Precautions

-

Do not use the pump in environments with flammable or explosive media, and do not pump flammable liquids.

-

Avoid impact or compression of the power cable, and never use the cable as a lifting rope.

-

Do not pull the cable during pump operation to avoid damaging the cable, which may lead to electrical accidents or compromise cable sealing and the insulation performance of the motor wiring compartment.

-

When using fixed automatic coupling installation, use a lifting chain and hook to lift the pump, ensuring to lift and lower gently.

-

When placing the pump into water, it should be lifted vertically. Do not place it horizontally or allow it to sink into sludge.

-

Install a flow control valve on the discharge pipeline to prevent excessive flow, which could overload the motor.

OEM & Custom

We provide OEM/ODM customization for global clients. Options include stainless steel versions, explosion-proof motors, extended cables, control panels, auto-coupling sets, and custom voltage/frequency configurations. Pumps can be tailored for municipal, mining, marine, or industrial wastewater systems, ensuring efficiency and long-term reliability.

FAQs

- Q: What’s the main difference between QW and WQ types?

- A: QW is a movable installation type, while WQ is fixed with automatic guide rail coupling for easier maintenance.

- Q: Can the pump handle solid or fibrous waste?

- A: Yes, the impeller design allows passage of solids up to 80 mm depending on model, preventing clogging.

- Q: What materials are available?

- A: Standard models use cast iron; optional stainless steel or duplex materials are available for corrosive media.

- Q: What voltages and frequencies are supported?

- A: Standard voltages 380 V/50 Hz; custom 220 V, 415 V, or 60 Hz versions are available upon request.

- Q: How is maintenance performed?

- A: Pumps use modular designs with quick-release seals and auto-coupling for easy inspection and part replacement.

- Q: Do you provide control panels or float switches?

- A: Yes, intelligent control cabinets and float switches can be supplied with the pump system.

- Q: What export markets do you serve?

- A: Our pumps are exported to Southeast Asia, Africa, South America, and the Middle East, meeting ISO and CE standards.