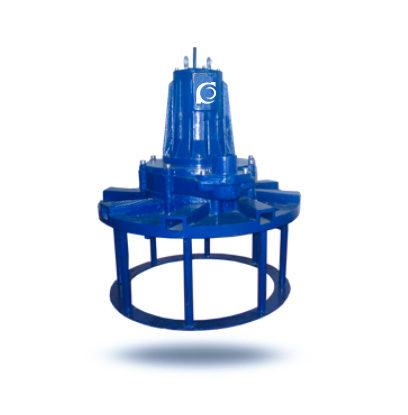

Product Overview

The QXB Submersible Centrifugal Aerator adopts a direct coupling structure and can operate as a self-priming aeration device. During operation, the rotating impeller generates centrifugal force and creates negative pressure at the impeller inlet, drawing in both air and water. The air and water are mixed in a fixed ratio within the mixing chamber, then directed through a flow channel and quickly dispersed into the surrounding medium. High-speed shearing generates fine bubbles that interact thoroughly with the water, ensuring effective aeration and oxygen transfer. This series is suitable for applications requiring solid-liquid mixing and stirring.

Model Designation

Key Features

-

Self-Priming Design: Built-in self-priming functionality, no external air source required, easy installation.

-

Compact Structure: Space-saving design, suitable for various installation environments.

-

Efficient Bubble Generation: High-speed shearing generates fine bubbles, enhancing gas-liquid interaction.

-

Leak-Free Operation: Ensures stable operation with no leakage, minimizing environmental contamination and safety risks.

-

Flexible Applications: Suitable for oxidation tanks and other industrial applications, optimizing cost structure.

Engineering Overview

The QXB aerator uses centrifugal force generated by the rotating impeller to draw in both air and water. With a static sealing design, the pumped media is fully isolated from the external environment, eliminating leakage risks. The high-efficiency bubble generation system enhances oxygen transfer efficiency and is widely applied in solid-liquid mixing and stirring processes.

Typical Applications

-

Wastewater Treatment: Suitable for industrial wastewater and municipal sewage treatment.

-

Chemical Processing: Used for mixing, stirring, and aeration in chemical processes.

-

Food Processing: Widely applied in food and beverage industries for gas dissolution and mixing.

-

Environmental Protection: Used in wastewater treatment and air purification applications.

-

Aquaculture: Provides essential oxygen supply and mixing functionality in aquaculture.

System Configuration

The QXB submersible centrifugal aerator system includes the following key components:

-

Aerator Main Unit: Includes motor, impeller, and water cooling system.

-

Control System: Includes regulator, valves, and automatic control devices for optimized operation.

-

Auxiliary Components: Such as water cooling system, intake and exhaust ducts, ensuring stable operation.

Components and Supply

-

Motor: High-efficiency motor ensuring continuous operation of the aerator.

-

Impeller: Precisely designed impeller for efficient gas-liquid mixing.

-

Water Cooling System: Effectively reduces the temperature of the motor and impeller, ensuring long-term stable operation.

-

Intake and Exhaust System: Ensures stable airflow, optimizing aeration performance.

Technical Service

-

24/7 customer service and technical support available.

-

Regular maintenance and inspections to extend equipment lifespan.

-

Customized services to provide specific system solutions based on customer requirements.

Operating Conditions

-

Operating Temperature: Suitable for temperatures ranging from 0°C to 50°C.

-

Operating Pressure: Suitable for standard pressure ranges with a maximum working pressure of 0.3 MPa.

-

Medium Requirements: Suitable for clean water, sewage, and other liquid media.

-

Medium Viscosity: Suitable for low to medium viscosity liquids.

Service Conditions

-

Regular Inspections: Full inspection every six months to ensure stable operation.

-

Maintenance Cycle: Recommended quarterly checks of the motor, impeller, and water cooling system.

-

Component Replacement: Periodically replace consumable parts such as impellers and water cooling filters based on usage.

Protection Features

-

Overload Protection: Automatically stops the operation if the system is overloaded to prevent damage.

-

Temperature Control Protection: Automatically stops the motor if the temperature exceeds the preset limits.

-

Leakage Protection: Built-in leakage detection system to ensure leak-free operation.

Selection Criteria

When selecting the QXB Submersible Centrifugal Aerator, consider the following criteria:

-

Medium Characteristics: Select a pump suitable for the type and physical properties of the medium.

-

Installation Environment: Choose a model that fits the available installation space and environmental conditions.

-

Flow and Head Requirements: Choose the appropriate flow and head capacity based on system requirements.

-

Energy Consumption: Opt for an energy-efficient aerator to reduce operational costs.+

Specifications & Installation

Outline Drawing

Performance Parameters

|

Model

|

Power (kW)

|

Rated Current (A)

|

Impeller Speed (r/min)

|

Effective Range Φ (m)

|

Submergence Depth (m)

|

Air Inlet Pipe Diameter (mm)

|

Air Intake (m³/h)

|

Weight (kg)

|

|

QXB0.75-32

|

0.75

|

2

|

1390

|

2.8

|

1–2

|

32

|

15–10

|

62

|

|

QXB1.5-32

|

1.5

|

3.7

|

1400

|

3.5

|

1–3

|

32

|

25–18

|

105

|

|

QXB2.2-50

|

2.2

|

5.2

|

1430

|

4.8

|

1–3.5

|

50

|

44–25

|

182

|

|

QXB3-50

|

3

|

6.8

|

1430

|

5.5

|

2–4

|

50

|

50–40

|

198

|

|

QXB4-50

|

4

|

8.8

|

1440

|

6.5

|

2–4

|

50

|

75–45

|

234

|

|

QXB5.5-65

|

5.5

|

11.8

|

1440

|

8.0

|

2–4.5

|

65

|

120–70

|

298

|

|

QXB7.5-80

|

7.5

|

15.6

|

1440

|

10

|

2–4.6

|

80

|

160–75

|

318

|

|

QXB11-80

|

11

|

22.3

|

1460

|

11

|

2–4.8

|

80

|

260–120

|

382

|

|

QXB15-100

|

15

|

30.1

|

1460

|

12

|

2–5

|

100

|

325–220

|

413

|

|

QXB18.5-100

|

18.5

|

36.5

|

1470

|

12.5

|

2–5

|

100

|

375–260

|

476

|

|

QXB22-100

|

22

|

43.2

|

1470

|

13.5

|

2–5.5

|

100

|

470–260

|

495

|

|

QXB30-150

|

30

|

56.8

|

1470

|

16

|

2–6

|

150

|

510–300

|

1200

|

|

QXB37-150

|

37

|

69.8

|

1480

|

16

|

2–6

|

150

|

570–390

|

1296

|

|

QXB45-150

|

45

|

84.2

|

1480

|

16

|

2–6

|

150

|

630–460

|

1380

|

|

QXB55-150

|

55

|

103

|

1480

|

16

|

2–6

|

150

|

825–620

|

1430

|

OEM & Custom

Chaodun Pump provides OEM and ODM customization for QXB series aerators, including stainless steel materials, high-efficiency impellers, and custom mounting bases. Export packaging, voltage, and branding options are available for global buyers.

FAQs

- 1. What is the QXB submersible aerator used for?

It is used for aeration and mixing in wastewater treatment and aquaculture ponds. - 2. Does it require an external air source?

No, it uses a self-priming system that automatically draws in air during operation. - 3. Can it operate continuously?

Yes, it is designed for long-term submerged operation. - 4. What is the working water depth?

Typically 1–6 meters, depending on model type. - 5. How is the impeller rotation checked?

Viewed from the bottom, the impeller should rotate counterclockwise. - 6. What materials are available?

Cast iron, stainless steel, and anti-corrosion coated versions are optional. - 7. Does Chaodun Pump offer OEM customization?

Yes, full OEM and export customization are supported.