Product Overview

The TSWA Series Horizontal Low-Speed Multistage Clean Water Pump is designed for transporting clean water and liquids with physical and chemical properties similar to water, and without solid particles.

It is primarily used in high-pressure water supply, high-rise building water supply, and industrial or mining drainage applications.

The pump’s flow range is from 10–155 m³/h, with a head range of 15–300 meters, and motor power ranging from 2.2–200 kilowatts. The nominal inlet/outlet size is between 50–150 mm, with a maximum liquid temperature of 80°C.

Model Designation

Key Features

-

Compact Design: The pump body adopts a compact design, occupying less space, making it suitable for high-rise buildings and industrial applications.

-

Low Noise and Low Vibration: Optimized hydraulic design and bearing configuration ensure the pump operates with low noise and low vibration.

-

Wide Applicability: Suitable for various clean water, hot water, high-temperature fluids, corrosive liquids, and petroleum products.

-

Easy to Maintain: The optimized structural design and removable components simplify the maintenance process.

Engineering Overview

The TSWA Pump adopts a horizontal multistage sectional structure, achieving high head performance through staged pressure accumulation.

The pump can precisely match the required flow and head conditions by selecting the appropriate number of stages and nozzle diameter.

It comes with a standard transverse suction and vertical discharge design, allowing for efficient integration into piping systems.

The pump and motor are mounted on a common cast iron base and connected through an elastic coupling, ensuring stable torque transmission and continuous operation.

Typical Applications

The TSWA Series Pump is widely used in the following fields:

-

Water Supply for High-rise Buildings

-

Normal Pressure Firefighting Systems

-

Automatic Sprinkler and Water Curtain Systems

-

Industrial and Mining Water Supply and Drainage

-

Long-distance Water Transport

-

Equipment Cooling and Circulation Systems

-

General Process Water Applications

The pump is suitable for clean water, seawater, lightly acidic or alkaline chemical liquids, and ordinary slurry media with moderate viscosity.

System Configuration

The TSWA Series Pump mainly consists of the following key components:

-

Hydraulic Section: Suction part, middle section, guide blades, and discharge part

-

Rotating Assembly: Shaft, impeller, balance disc, and shaft sleeve

-

Bearing Assembly: Lubricated rolling bearings for smooth, low-noise operation

-

Sealing System: Soft packing seals, rubber water seal rings, and O-rings for leakage control

Components and Supply

The TSWA Series Pump includes the following major components:

-

Pump Housing and Impeller Assembly: Optimized hydraulic performance

-

Electric Motor: Direct coupling with extended shaft

-

Mechanical Seal System: Single-type or combination-type seals

-

Pipeline Flanges and Structural Mounting Parts: Standard fittings for system connections

Technical Service

We offer comprehensive technical support, including installation, commissioning, and maintenance services for the TSWA Pumps. Our team ensures that the pump operates efficiently and reliably throughout its service life.

Operating Conditions

-

Medium: Clean water, seawater, lightly acidic or alkaline liquids

-

Maximum Viscosity: ≤100 cP

-

Maximum Solid Content: ≤30%

-

Cooling Requirements: External cooling water is required if the bearing housing temperature exceeds 70°C

Service Conditions

-

Medium Properties: Suitable for clean water or similar liquids

-

Solid Content: ≤1%, particle size ≤0.1 mm

-

Bearing Lubrication: Calcium-based grease

Protection Functions

-

Self-priming Ability: Optimized gas-liquid separation technology for more reliable self-priming performance.

-

Temperature Monitoring: Optional external cooling water system to maintain bearing temperature within a safe range.

Selection Criteria

The selection of the pump should be based on the actual application requirements, including the type of medium, flow rate, working pressure, and temperature conditions. Ensure that the appropriate seal type and cooling solutions are selected to ensure the pump’s long-term stable operation.

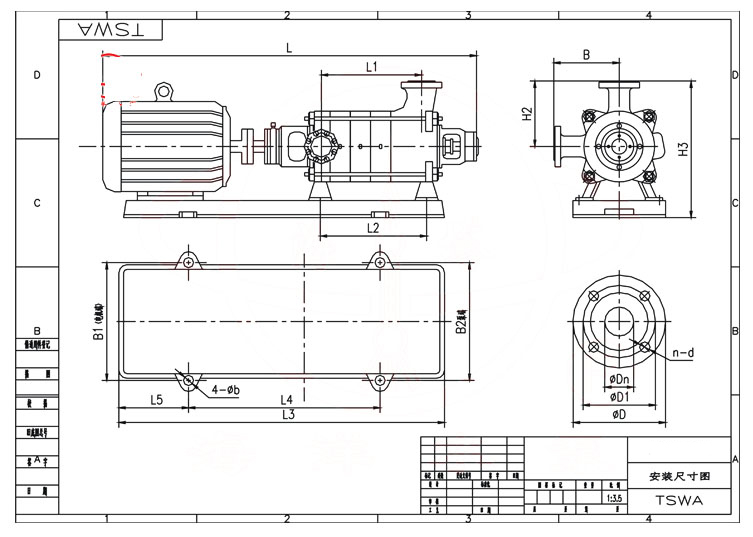

Installation & Dimensions

Outline Drawing

Performance Data

|

No.

|

Name

|

Material

|

No.

|

Name

|

Material

|

No.

|

Name

|

Material

|

No.

|

Name

|

Material

|

|

1

|

Coupling

|

HT200

|

7

|

Guide Vane

|

HT200

|

13

|

Balance Plate

|

HT200

|

19

|

Right Bearing Cover

|

HT200

|

|

2

|

Left Bearing Cover

|

HT200

|

8

|

Middle Section

|

HT200

|

14

|

Packing Body

|

HT200

|

20

|

Left Bearing Cover

|

Q235

|

|

3

|

Left Bearing Seat

|

HT200

|

End Guide Vane

|

HT200

|

15

|

Right Bearing Seat

|

HT200

|

21

|

Bearing

|

Tin Bronze

|

Tin bronze |

|

4

|

Left Packing Cover

|

HT200

|

10

|

Outlet Section

|

HT200

|

16

|

Right Packing Cover

|

HT200

|

22

|

Left Bearing Sleeve

|

Q235

|

|

5

|

Inlet Section

|

HT200

|

11

|

Balance Section

|

HT200

|

17

|

Right Packing Sleeve

|

Q235

|

23

|

Left Packing Sleeve

|

Q235

|

|

6

|

Impeller

|

HT200

|

12

|

Balance Ring

|

HT200

|

18

|

Right Bearing Sleeve

|

Q235

|

24

|

Shaft

|

45 or 2Cr13

|

Performance Curves

Performance Parameters

|

Model

|

Stages

|

Flow Rate

|

Head

|

Speed

|

Power (kW)

|

Efficiency

|

Permissible Suction Vacuum

|

NPSH

|

Weight

|

||

|

m3/h

|

L/S

|

m

|

r/min

|

Shaft Power

|

Motor Power (kW)

|

%

|

m

|

m

|

kg

|

||

|

50TSWA18-9.2*2

|

2

|

18

|

5

|

18.4

|

1450

|

1.37

|

2.2

|

66

|

7.2

|

3.1

|

135

|

|

50TSWA18-9.2*3

|

3

|

18

|

5

|

27.6

|

1450

|

2.05

|

3

|

66

|

7.2

|

3.1

|

155

|

|

50TSWA18-9.2*4

|

4

|

18

|

5

|

36.8

|

1450

|

2.73

|

4

|

66

|

7.2

|

3.1

|

175

|

|

50TSWA18-9.2*5

|

5

|

18

|

5

|

46

|

1450

|

3.42

|

5.5

|

66

|

7.2

|

3.1

|

195

|

|

50TSWA18-9.2*6

|

6

|

18

|

5

|

55.2

|

1450

|

4.1

|

5.5

|

66

|

7.2

|

3.1

|

215

|

|

50TSWA18-9.2*7

|

7

|

18

|

5

|

64.4

|

1450

|

4.79

|

7.5

|

66

|

7.2

|

3.1

|

235

|

|

50TSWA18-9.2*8

|

8

|

18

|

5

|

73.6

|

1450

|

5.47

|

7.5

|

66

|

7.2

|

3.1

|

155

|

|

50TSWA18-9.2*9

|

9

|

18

|

5

|

82.8

|

1450

|

6.15

|

7.5

|

66

|

7.2

|

3.1

|

275

|

|

50TSWA18-9.2*10

|

10

|

18

|

5

|

92

|

1450

|

6.84

|

11

|

66

|

7.2

|

3.1

|

295

|

|

50TSWA18-9.2*11

|

11

|

18

|

5

|

101.2

|

1450

|

7.52

|

11

|

66

|

7.2

|

3.1

|

315

|

|

50TSWA18-9.2*12

|

12

|

18

|

5

|

110.4

|

1450

|

8.2

|

11

|

66

|

7.2

|

3.1

|

335

|

|

Model

|

Stages

|

Flow Rate

|

Head

|

Speed

|

Power (kW)

|

Efficiency

|

Permissible Suction Vacuum

|

NPSH

|

Weight

|

||

|

m3/h

|

L/S

|

m

|

r/min

|

Shaft Power

|

Motor Power (kW)

|

%

|

m

|

m

|

kg

|

||

|

75TSWA36-11.5*2

|

2

|

36

|

10

|

23

|

1450

|

3.22

|

5.5

|

70

|

7.2

|

3

|

|

|

75TSWA36-11.5*3

|

3

|

36

|

10

|

34.5

|

1450

|

4.83

|

7.5

|

70

|

7.2

|

3

|

|

|

75TSWA36-11.5*4

|

4

|

36

|

10

|

46

|

1450

|

6.45

|

11

|

70

|

7.2

|

3

|

|

|

75TSWA36-11.5*5

|

5

|

36

|

10

|

57.5

|

1450

|

8.06

|

11

|

70

|

7.2

|

3

|

|

|

75TSWA36-11.5*6

|

6

|

36

|

10

|

69

|

1450

|

9.67

|

15

|

70

|

7.2

|

3

|

|

|

75TSWA36-11.5*7

|

7

|

36

|

10

|

80.5

|

1450

|

11.28

|

15

|

70

|

7.2

|

3

|

|

|

75TSWA36-11.5*8

|

8

|

36

|

10

|

92.5

|

1450

|

12.89

|

18.5

|

70

|

7.2

|

3

|

|

|

75TSWA36-11.5*9

|

9

|

36

|

10

|

103.5

|

1450

|

14.5

|

18.5

|

70

|

7.2

|

3

|

|

|

75TSWA36-11.5*10

|

10

|

36

|

10

|

115

|

1450

|

16.12

|

22

|

70

|

7.2

|

3

|

|

|

75TSWA36-11.5*11

|

11

|

36

|

10

|

126.5

|

1450

|

17.73

|

22

|

70

|

7.2

|

3

|

|

|

Model

|

Stages

|

Flow Rate

|

Head

|

Speed

|

Power (kW)

|

Efficiency

|

Permissible Suction Vacuum

|

NPSH

|

Weight

|

||

|

m3/h

|

L/S

|

m

|

r/min

|

Shaft Power

|

Motor Power (kW)

|

%

|

m

|

m

|

kg

|

||

|

100TSWA69-15.6*2

|

2

|

69

|

19.2

|

31.2

|

1450

|

8.03

|

11

|

73

|

7

|

3.3

|

|

|

100TSWA69-15.6*3

|

3

|

69

|

19.2

|

46.8

|

1450

|

12.05

|

15

|

73

|

7

|

3.3

|

|

|

100TSWA69-15.6*4

|

4

|

69

|

19.2

|

62.4

|

1450

|

16.07

|

22

|

73

|

7

|

3.3

|

|

|

100TSWA69-15.6*5

|

5

|

69

|

19.2

|

78

|

1450

|

20.09

|

30

|

73

|

7

|

3.3

|

|

|

100TSWA69-15.6*6

|

6

|

69

|

19.2

|

93.6

|

1450

|

24.11

|

30

|

73

|

7

|

3.3

|

|

|

100TSWA69-15.6*7

|

7

|

69

|

19.2

|

109.1

|

1450

|

28.13

|

37

|

73

|

7

|

3.3

|

|

|

100TSWA69-15.6*8

|

8

|

69

|

19.2

|

124.8

|

1450

|

32.14

|

45

|

73

|

7

|

3.3

|

|

|

100TSWA69-15.6*9

|

9

|

69

|

19.2

|

140.4

|

1450

|

36.16

|

45

|

73

|

7

|

3.3

|

|

|

100TSWA69-15.6*10

|

10

|

69

|

19.2

|

156

|

1450

|

40.18

|

55

|

73

|

7

|

3.3

|

|

|

Model

|

Stages

|

Flow Rate

|

Head

|

Speed

|

Power (kW)

|

Efficiency

|

Permissible Suction Vacuum

|

NPSH

|

Weight

|

||

|

m3/h

|

L/S

|

m

|

r/min

|

Shaft Power

|

Motor Power (kW)

|

%

|

m

|

m

|

kg

|

||

|

125TSWA90-21.6*2

|

2

|

90

|

25

|

43.2

|

1450

|

14.32

|

22

|

74

|

6.8

|

3.4

|

|

|

125TSWA90-21.6*3

|

3

|

90

|

25

|

64.8

|

1450

|

21.48

|

30

|

74

|

6.8

|

3.4

|

|

|

125TSWA90-21.6*4

|

4

|

90

|

25

|

86.4

|

1450

|

28.63

|

45

|

74

|

6.8

|

3.4

|

|

|

125TSWA90-21.6*5

|

5

|

90

|

25

|

108

|

1450

|

35.79

|

55

|

74

|

6.8

|

3.4

|

|

|

125TSWA90-21.6*6

|

6

|

90

|

25

|

129.6

|

1450

|

42.95

|

75

|

74

|

6.8

|

3.4

|

|

|

125TSWA90-21.6*7

|

7

|

90

|

25

|

151.2

|

1450

|

50.11

|

75

|

74

|

6.8

|

3.4

|

|

|

125TSWA90-21.6*8

|

8

|

90

|

25

|

172.8

|

1450

|

57.27

|

90

|

74

|

6.8

|

3.4

|

|

|

125TSWA90-21.6*9

|

9

|

90

|

25

|

194.4

|

1450

|

64.43

|

90

|

74

|

6.8

|

3.4

|

|

|

125TSWA90-21.6*10

|

10

|

90

|

25

|

216

|

1450

|

71.59

|

90

|

74

|

6.8

|

3.4

|

|

|

Model

|

Stages

|

Flow Rate

|

Head

|

Speed

|

Power (kW)

|

Efficiency

|

Permissible Suction Vacuum

|

NPSH

|

Weight

|

||

|

m3/h

|

L/S

|

m

|

r/min

|

Shaft Power

|

Motor Power (kW)

|

%

|

m

|

m

|

kg

|

||

|

150TSWA155-30*2

|

2

|

155

|

43

|

60

|

1450

|

32.91

|

45

|

77

|

7.7

|

2.5

|

|

|

150TSWA155-30*3

|

3

|

155

|

43

|

90

|

1450

|

49.37

|

75

|

77

|

7.7

|

2.5

|

|

|

150TSWA155-30*4

|

4

|

155

|

43

|

120

|

1450

|

65.82

|

90

|

77

|

7.7

|

2.5

|

|

|

150TSWA155-30*5

|

5

|

155

|

43

|

150

|

1450

|

82.28

|

110

|

77

|

7.7

|

2.5

|

|

|

150TSWA155-30*6

|

6

|

155

|

43

|

180

|

1450

|

98.74

|

132

|

77

|

7.7

|

2.5

|

|

|

150TSWA155-30*7

|

7

|

155

|

43

|

210

|

1450

|

115.19

|

132

|

77

|

7.7

|

2.5

|

|

|

150TSWA155-30*8

|

8

|

155

|

43

|

240

|

1450

|

131.19

|

160

|

77

|

7.7

|

2.5

|

|

|

150TSWA155-30*9

|

9

|

155

|

43

|

270

|

1450

|

148.1

|

200

|

77

|

7.7

|

2.5

|

|

Installation Diagram

Performance Data(2)

Performance Data(2)

|

Model

|

Stages

|

Pump Dimensions (H2 = B)

|

Base Dimensions

|

Inlet & Outlet Flange

|

||||||||||||

|

L

|

L1

|

L2

|

B

|

H3

|

L3

|

L4

|

L5

|

B1

|

B2

|

4-φb

|

D

|

D1

|

Dn

|

n-φd

|

||

|

50TSWA18-9.2*2

|

2

|

1087

|

160

|

145

|

230

|

480

|

901

|

600

|

33

|

335

|

430

|

4-φ25

|

160

|

125

|

50

|

4-φ18

|

|

50TSWA18-9.2*3

|

3

|

1152

|

225

|

210

|

230

|

480

|

901

|

600

|

33

|

335

|

430

|

4-φ25

|

160

|

125

|

50

|

4-φ18

|

|

50TSWA18-9.2*4

|

4

|

1237

|

290

|

275

|

230

|

480

|

974

|

640

|

128

|

375

|

430

|

4-φ25

|

160

|

125

|

50

|

4-φ18

|

|

50TSWA18-9.2*5

|

5

|

1377

|

355

|

340

|

230

|

490

|

1153

|

740

|

132

|

430

|

430

|

4-φ25

|

160

|

125

|

50

|

4-φ18

|

|

50TSWA18-9.2*6

|

6

|

1442

|

420

|

405

|

230

|

490

|

1153

|

740

|

197

|

430

|

430

|

4-φ25

|

160

|

125

|

50

|

4-φ18

|

|

50TSWA18-9.2*7

|

7

|

1547

|

485

|

470

|

230

|

490

|

1321

|

840

|

197

|

430

|

430

|

4-φ25

|

160

|

125

|

50

|

4-φ18

|

|

50TSWA18-9.2*8

|

8

|

1612

|

550

|

535

|

230

|

490

|

1321

|

840

|

262

|

430

|

430

|

4-φ25

|

160

|

125

|

50

|

4-φ18

|

|

50TSWA18-9.2*9

|

9

|

1677

|

615

|

600

|

230

|

490

|

1386

|

860

|

297

|

430

|

430

|

4-φ25

|

160

|

125

|

50

|

4-φ18

|

|

50TSWA18-9.2*10

|

10

|

1827

|

680

|

665

|

230

|

490

|

1593

|

900

|

362

|

430

|

430

|

4-φ25

|

160

|

125

|

50

|

4-φ18

|

|

50TSWA18-9.2*11

|

11

|

1930

|

745

|

730

|

230

|

490

|

1593

|

1000

|

427

|

430

|

430

|

4-φ25

|

160

|

125

|

50

|

4-φ18

|

|

50TSWA18-9.2*12

|

12

|

1957

|

810

|

795

|

230

|

490

|

1658

|

1200

|

462

|

430

|

430

|

4-φ25

|

160

|

125

|

50

|

4-φ18

|

|

Model

|

Stages

|

Pump Dimensions (H2 = B)

|

Base Dimensions

|

Inlet & Outlet Flange

|

||||||||||||

|

L

|

L1

|

L2

|

B

|

H3

|

L3

|

L4

|

L5

|

B1

|

B2

|

4-φb

|

D

|

D1

|

Dn

|

n-φd

|

||

|

75TSWA36-11.5*2

|

2

|

1241

|

177

|

180

|

250

|

535

|

1046

|

690

|

89

|

410

|

475

|

4-φ25

|

195

|

160

|

80

|

4-φ18

|

|

75TSWA36-11.5*3

|

3

|

1361

|

257

|

260

|

250

|

545

|

1046

|

690

|

128

|

410

|

475

|

4-φ25

|

195

|

160

|

80

|

4-φ18

|

|

75TSWA36-11.5*4

|

4

|

1526

|

337

|

340

|

250

|

545

|

1284

|

830

|

171

|

475

|

475

|

4-φ25

|

195

|

160

|

80

|

4-φ18

|

|

75TSWA36-11.5*5

|

5

|

1606

|

417

|

420

|

250

|

545

|

1284

|

830

|

211

|

475

|

475

|

4-φ25

|

195

|

160

|

80

|

4-φ18

|

|

75TSWA36-11.5*6

|

6

|

1731

|

497

|

500

|

250

|

545

|

1488

|

980

|

245

|

475

|

475

|

4-φ25

|

195

|

160

|

80

|

4-φ18

|

|

75TSWA36-11.5*7

|

7

|

1811

|

577

|

580

|

250

|

545

|

1488

|

980

|

245

|

475

|

475

|

4-φ25

|

195

|

160

|

80

|

4-φ18

|

|

75TSWA36-11.5*8

|

8

|

1916

|

657

|

660

|

250

|

560

|

1653

|

1150

|

239

|

480

|

480

|

4-φ25

|

195

|

160

|

80

|

4-φ18

|

|

75TSWA36-11.5*9

|

9

|

1996

|

737

|

740

|

250

|

560

|

1653

|

1150

|

239

|

480

|

480

|

4-φ25

|

195

|

160

|

80

|

4-φ18

|

|

75TSWA36-11.5*10

|

10

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

|

75TSWA36-11.5*11

|

11

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

|

Model

|

Stages

|

Pump Dimensions (H2 = B)

|

Base Dimensions

|

Inlet & Outlet Flange

|

||||||||||||

|

L

|

L1

|

L2

|

B

|

H3

|

L3

|

L4

|

L5

|

B1

|

B2

|

4-φb

|

D

|

D1

|

Dn

|

n-φd

|

||

|

100TSWA69-15.6*2

|

2

|

1575

|

255

|

200

|

310

|

610

|

1322

|

900

|

100

|

505

|

505

|

4-φ30

|

230

|

190

|

100

|

8-φ23

|

|

100TSWA69-15.6*3

|

3

|

1720

|

355

|

300

|

310

|

610

|

1322

|

900

|

149

|

505

|

505

|

4-φ30

|

230

|

190

|

100

|

8-φ23

|

|

100TSWA69-15.6*4

|

4

|

1885

|

455

|

400

|

310

|

610

|

1463

|

975

|

200

|

505

|

505

|

4-φ30

|

230

|

190

|

100

|

8-φ23

|

|

100TSWA69-15.6*5

|

5

|

2050

|

555

|

500

|

310

|

620

|

1701

|

1240

|

202

|

525

|

525

|

4-φ30

|

230

|

190

|

100

|

8-φ23

|

|

100TSWA69-15.6*6

|

6

|

2150

|

655

|

600

|

310

|

620

|

1701

|

1240

|

157

|

525

|

525

|

4-φ30

|

230

|

190

|

100

|

8-φ23

|

|

100TSWA69-15.6*7

|

7

|

2295

|

755

|

700

|

310

|

630

|

1959

|

1450

|

198

|

565

|

565

|

4-φ30

|

230

|

190

|

100

|

8-φ23

|

|

100TSWA69-15.6*8

|

8

|

2420

|

855

|

800

|

310

|

640

|

1959

|

1450

|

199

|

565

|

565

|

4-φ30

|

230

|

190

|

100

|

8-φ23

|

|

100TSWA69-15.6*9

|

9

|

2520

|

955

|

900

|

310

|

640

|

2059

|

1550

|

199

|

565

|

565

|

4-φ30

|

230

|

190

|

100

|

8-φ23

|

|

100TSWA69-15.6*10

|

10

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

|

Model

|

Stages

|

Pump Dimensions (H2 = B)

|

Base Dimensions

|

Inlet & Outlet Flange

|

||||||||||||

|

L

|

L1

|

L2

|

B

|

H3

|

L3

|

L4

|

L5

|

B1

|

B2

|

4-φb

|

D

|

D1

|

Dn

|

n-φd

|

||

|

125TSWA90-21.6*2

|

2

|

1740

|

270

|

205

|

320

|

670

|

1312

|

990

|

220

|

500

|

500

|

4-φ30

|

270

|

220

|

125

|

8-φ25

|

|

125TSWA90-21.6*3

|

3

|

1890

|

370

|

305

|

320

|

670

|

1449

|

1000

|

230

|

500

|

500

|

4-φ30

|

270

|

220

|

125

|

8-φ25

|

|

125TSWA90-21.6*4

|

4

|

2060

|

470

|

405

|

320

|

680

|

1603

|

1100

|

240

|

520

|

520

|

4-φ30

|

270

|

220

|

125

|

8-φ25

|

|

125TSWA90-21.6*5

|

5

|

2250

|

570

|

505

|

320

|

695

|

1774

|

1170

|

270

|

570

|

520

|

4-φ30

|

270

|

220

|

125

|

8-φ25

|

|

125TSWA90-21.6*6

|

6

|

2420

|

670

|

605

|

320

|

725

|

2005

|

1260

|

305

|

630

|

520

|

4-φ30

|

270

|

220

|

125

|

8-φ25

|

|

125TSWA90-21.6*7

|

7

|

2520

|

770

|

705

|

320

|

725

|

2005

|

1260

|

305

|

630

|

520

|

4-φ30

|

270

|

220

|

125

|

8-φ25

|

|

125TSWA90-21.6*8

|

8

|

2670

|

870

|

805

|

320

|

725

|

2243

|

1430

|

305

|

630

|

570

|

4-φ30

|

270

|

220

|

125

|

8-φ25

|

|

125TSWA90-21.6*9

|

9

|

2770

|

970

|

905

|

320

|

725

|

2243

|

1430

|

305

|

630

|

520

|

4-φ30

|

270

|

220

|

125

|

8-φ25

|

|

125TSWA90-21.6*10

|

10

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

|

Model

|

Stages

|

Pump Dimensions (H2 = B)

|

Base Dimensions

|

Inlet & Outlet Flange

|

||||||||||||

|

L

|

L1

|

L2

|

B

|

H3

|

L3

|

L4

|

L5

|

B1

|

B2

|

4-φb

|

D

|

D1

|

Dn

|

n-φd

|

||

|

150TSWA155-30*2

|

2

|

1964

|

236

|

237

|

350

|

720

|

1437

|

1000

|

80

|

720

|

575

|

4-φ30

|

280

|

240

|

150

|

8-φ23

|

|

150TSWA155-30*3

|

3

|

2234

|

350

|

352

|

350

|

735

|

1735

|

1165

|

148

|

735

|

675

|

4-φ30

|

280

|

240

|

150

|

8-φ23

|

|

150TSWA155-30*4

|

4

|

2399

|

465

|

467

|

350

|

745

|

1922

|

1260

|

215

|

745

|

675

|

4-φ30

|

280

|

240

|

150

|

8-φ23

|

|

150TSWA155-30*5

|

5

|

2664

|

580

|

582

|

350

|

780

|

2129

|

1470

|

212

|

780

|

765

|

4-φ30

|

280

|

240

|

150

|

8-φ23

|

|

150TSWA155-30*6

|

6

|

2829

|

695

|

697

|

350

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

|

150TSWA155-30*7

|

7

|

2944

|

810

|

812

|

350

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

|

150TSWA155-30*8

|

8

|

3019

|

925

|

927

|

350

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

|

150TSWA155-30*9

|

9

|

3224

|

1040

|

1042

|

350

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

Operating Manual

(I) Preparations Before Installation:

-

Prepare installation tools and lifting equipment.

-

Check if any part of the pump unit has loosened or been damaged during transportation.

-

Ensure the foundation is level.

(II) Installation Sequence:

-

Upon arrival at the site, if the unit includes a base, the pump and motor will have already been aligned at the factory. Therefore, there is no need for re-alignment during leveling, making the installation process highly efficient.

-

Place the base on the foundation, position wedge-shaped steel plates near the anchor bolts, and raise the base by 20–40 mm for subsequent leveling and cement grouting.

-

Use a level gauge to check the flatness of the base. After leveling, fill the base with cement grout. Once the cement has dried, check the level again.

-

For units with higher power ratings, the pump, motor, and base may be packaged separately for ease of transportation. In this case, follow these steps for installation and alignment:

a. Clean the supporting surface of the base and the mounting surfaces of the pump and motor, then place the pump and motor onto the base.

b. Adjust the pump shaft to a level position, and securely fix the pump to the base with bolts to prevent movement.

c. Lift the motor, align the motor coupling with the pump coupling, and lower the motor into its correct position on the base.

d. Adjust the coupling gap to approximately 5 mm and check if the motor shaft and pump shaft are properly aligned. Use a straightedge to verify that both coupling outer circles are flush. If not, adjust the position of the motor or pump or use shims to correct the alignment.

e. To verify installation accuracy, use a feeler gauge to measure the gap between the coupling faces at several points around the circumference. The difference between the maximum and minimum values should not exceed 0.3 mm, and the difference between the centerlines (up/down/left/right) should not exceed 0.1 mm. -

If the unit does not include a base, it must be installed directly on the foundation. The method is similar to step 4, but extra attention is required for alignment.

(III) Installation Precautions:

-

The pipeline must not exert any force on the pump during installation, as this may cause damage to the pump.

-

Anchor bolts must be tightened during installation. Periodically check to ensure they do not loosen, which could cause severe vibration during pump operation.

-

Before installation, check the pump passage for any hard objects (e.g., stones, iron sand) to prevent damage to the flow parts during operation.

-

To facilitate maintenance and ensure safe operation, install regulating valves and pressure gauges on both the inlet and outlet pipelines.

-

For high-head pumps, install a check valve before the outlet gate valve to prevent water hammer during sudden power failure and ensure long-term stable operation.

-

When operating under suction conditions, a foot valve must be installed. The inlet pipeline should not have excessive bends and must be free from leaks to maintain suction efficiency.

-

To prevent debris from entering the pump and blocking the flow passage, install a filter before the pump inlet.

-

Before connecting the pipeline, manually rotate the pump rotor to ensure it moves freely with no friction or jamming.

-

The pump flanges are designed according to 2.5 MPa standards, so select matching pipeline flanges accordingly.

Startup, Shutdown & Operation

1. Preparations Before Startup:

-

Manually rotate the pump rotor—ensure it rotates freely without friction.

-

Open the inlet valve, close the outlet valve, remove air from the pump, and fill it with liquid.

-

Jog the motor to confirm the rotation direction. If incorrect, swap any two motor wires.

2. Startup & Operation:

-

Fully open the inlet valve and close the outlet valve.

-

Start the motor. After the pump reaches full speed, gradually open the outlet valve and adjust it to the required operating condition.

-

Check instrument readings.

-

Bearing temperature should not exceed 75°C, and should not be more than 35°C above ambient temperature.

3. Shutdown Procedure:

-

Gradually close the outlet valve and disconnect the power supply.

-

Close the inlet valve.

-

If the ambient temperature is below 0°C, drain all liquid to prevent the pump casing from freezing and cracking.

-

For long-term shutdown, disassemble, clean, and properly store the pump.

Maintenance & Care

-

The inlet pipeline must be completely sealed—no air or water leakage is allowed.

-

Long-term cavitation operation is strictly prohibited.

-

Do not operate the pump for extended periods with excessive flow, as this could overload the motor.

-

Regularly check the motor current to ensure operation within the rated working conditions.

-

The pump must be monitored by dedicated personnel to prevent accidents.

-

Lubricate bearings every 500 hours of operation.

-

After long-term use, mechanical wear may cause increased noise and vibration. Stop the pump for inspection and replace worn parts and bearings if necessary. A typical overhaul period is one year.

-

If a fault occurs during operation, troubleshoot according to the provided fault table. If the issue cannot be resolved, do not disassemble the pump yourself—contact our service department or authorized repair center.

OEM & Custom

We offer OEM/ODM services including customization of voltage (220V/380V/415V), materials (cast iron, stainless steel, bronze), and flange standards (DIN/ANSI/JIS). Optional coatings, mechanical seal types, and bearing brands (SKF, NSK) are available. All products are ISO9001 and CE certified for export.

FAQs

- Q: What type of liquids can TSWA pumps handle?

A: Clean water and similar liquids with temperatures up to 80°C. - Q: What’s the difference between TSWA and IS pumps?

A: TSWA is multistage for high head applications, while IS is single stage for general supply. - Q: What are the main applications?

A: Building water supply, firefighting systems, factory circulation, and irrigation. - Q: What’s the efficiency level?

A: Up to 82%, depending on model and operating conditions. - Q: Can it be customized for export standards?

A: Yes, materials, voltage, and flange standards can be customized for overseas projects. - Q: Which certifications are available?

A: ISO9001 and CE certificates ensure international compliance. - Q: What about spare parts availability?

A: We provide full spare parts support and long-term technical service for global buyers.