Product Overview

The TSWA Horizontal Low-Speed Multistage Centrifugal Pump is a horizontal, low-speed multistage centrifugal pump designed for conveying clean water or liquids with physical and chemical properties similar to clean water, free of solid particles.

This pump series is mainly applied in high-pressure water supply, high-rise building water supply, and industrial water transfer and drainage services, featuring high head capability and stable operation.

The performance range covers flow 10–155 m³/h, head 15–300 m, matching motor power 2.2–200 kW, with allowable medium temperature ≤ 80°C.

Model Designation

Key Features

-

Low-speed multistage design: Reduces vibration and noise, improving operational stability and service life.

-

Wide high-head coverage: Reduces the need for multiple pumps in series, simplifying system design.

-

Compact arrangement: Saves pump room space and lowers civil and installation costs.

-

Maintenance-friendly layout: Well-arranged bearings and motor configuration supports easier inspection and servicing.

Engineering Summary

-

A horizontal low-speed multistage configuration with a compact overall arrangement, effectively reducing footprint and foundation civil work costs.

-

The rotor assembly is supported by rolling bearings at both ends, ensuring long-term operational stability and reliability.

-

Horizontal suction inlet and vertically upward discharge outlet facilitate piping layout and on-site installation.

-

Horizontal motor installation allows convenient routine inspection, maintenance, and replacement.

Typical Applications

-

Domestic water supply systems for high-rise buildings

-

Constant-pressure firefighting water supply, automatic sprinkler systems, and water curtain systems

-

Industrial and mining water supply and drainage systems

-

Long-distance water conveyance, auxiliary water supply for equipment packages, and various process water duties

The pump is suitable for continuous-duty operation, running smoothly with low noise, and meeting water supply requirements demanding high head and stable flow delivery.

System & Operation

Components & Supply

- Casing Assembly: Includes suction section, stage sections, and discharge section, forming the complete multistage boosting structure.

- Impellers and Diffuser Components: A multistage impeller and diffuser arrangement delivers stable, staged pressure boosting.

- Rotor and Bearing System: Pump shaft and rolling bearing assemblies at both ends ensure smooth running and shaftline reliability.

- Drive and Coupling Components: Matched electric motor, coupling, and common baseplate enable integrated pump set operation.

Technical Specifications

Operating Conditions

-

Before start-up, ensure the pump casing and piping are fully filled with the medium; dry running is strictly prohibited.

-

During operation, avoid prolonged deviation from the design duty point to prevent abnormal wear of bearings and impellers.

-

System operating pressure shall not exceed the allowable design limit to prevent overpressure damage.

-

After an extended shutdown, check bearing lubrication condition and coupling status before restarting.

Service Conditions

- Medium Cleanliness Requirement: The medium shall be clean water or similar liquids, free of fibers and solid particles.

- Solids Content Limitatio: Solid impurities by volume ≤ 0.1%, with particle diameter ≤ 2 mm.

- Temperature and Ambient Limitations: Medium temperature range –15°C to 80°C; ambient temperature ≤ 40°C, relative humidity ≤ 95%.

- Material Suitability Limitation: As major wetted components are cast iron, the pump is not suitable for strongly corrosive media.

Protection Functions

- Motor Overload Protection: Prevents motor damage caused by overload operation.

- Phase-Loss and Short-Circuit Protectio: Ensures safe motor operation under abnormal power supply conditions.

- Overtemperature Protection: Prevents overheating of bearings or motor through temperature-rise monitoring.

- System Interlock Protection: Pressure or level interlock control can be configured according to system requirements.

Selection Criteria

- Flow and Head Matching: Determine design flow and total head based on actual demand, keeping the operating point close to the high-efficiency region.

- System Pressure Verification: Selection shall account for inlet pressure, pipeline losses, and the maximum system operating pressure.

- Duty Profile Assessment: Evaluate continuous or intermittent operation and avoid long-term low-flow running or overload operation.

- Medium Property Confirmation: Confirm medium temperature, cleanliness, and whether trace fine particles exist.

- Energy Efficiency and Maintenance Considerations: Select based on a combined evaluation of long-term energy consumption and serviceability.

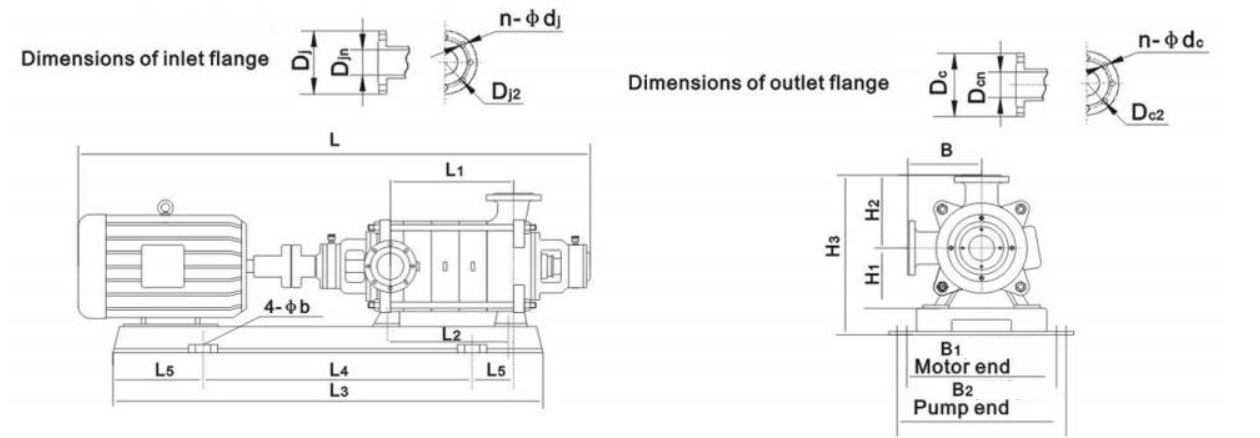

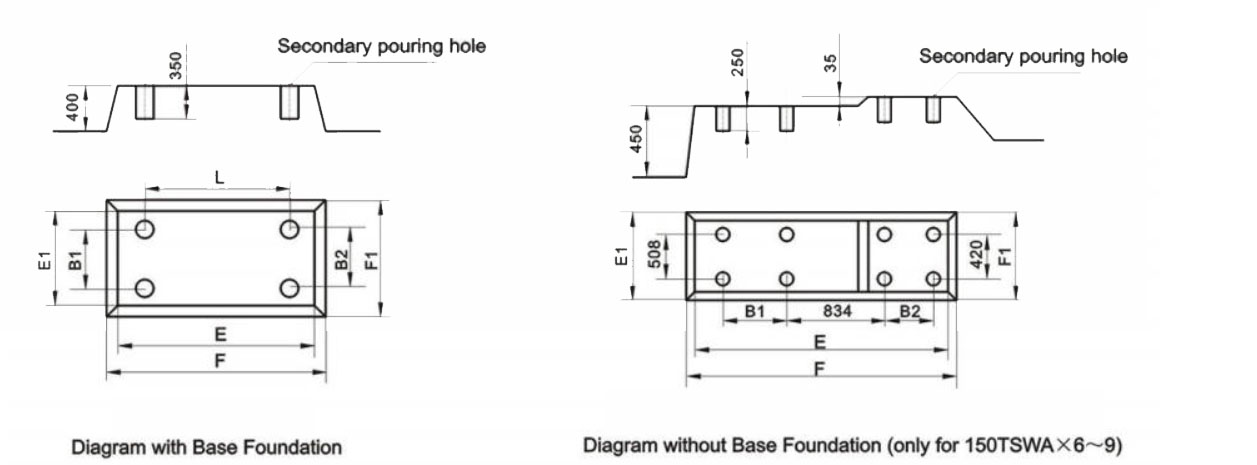

Installation Dimensions/Size

Outline Drawing

Pump Parts & Materials List

|

Item No.

|

Coupling Name

|

Material

|

No.

|

Coupling Name

|

Material

|

Item No.

|

Coupling Name

|

Material

|

Item No.

|

Coupling Name

|

Material

|

|

1

|

Coupling

|

HT200

|

7

|

Guide vane

|

HT200

|

13

|

Balancing disc

|

HT200

|

19

|

Right bearing gland

|

HT200

|

|

2

|

Left bearing gland

|

HT200

|

8

|

Middle section

|

HT200

|

14

|

Packing body

|

HT200

|

20

|

Left bearing gland

|

Q235

|

|

3

|

Left bearing housing

|

HT200

|

9

|

Last guide vane

|

HT200

|

15

|

Right bearing housing

|

HT200

|

21

|

Bearing

|

Tin bronze

|

|

4

|

Left packing gland

|

HT200

|

10

|

Discharge section

|

HT200

|

16

|

Right packing gland

|

HT200

|

22

|

Left bearing bush

|

Q235

|

|

5

|

Suction section

|

HT200

|

11

|

Balancing section

|

HT200

|

17

|

Right packing sleeve

|

Q235

|

23

|

Left packing sleeve

|

Q235

|

|

6

|

Impeller

|

HT200

|

12

|

Balancing ring

|

HT200

|

18

|

Right bearing bush

|

Q235

|

24

|

Shaft

|

45 or 2Cr13

|

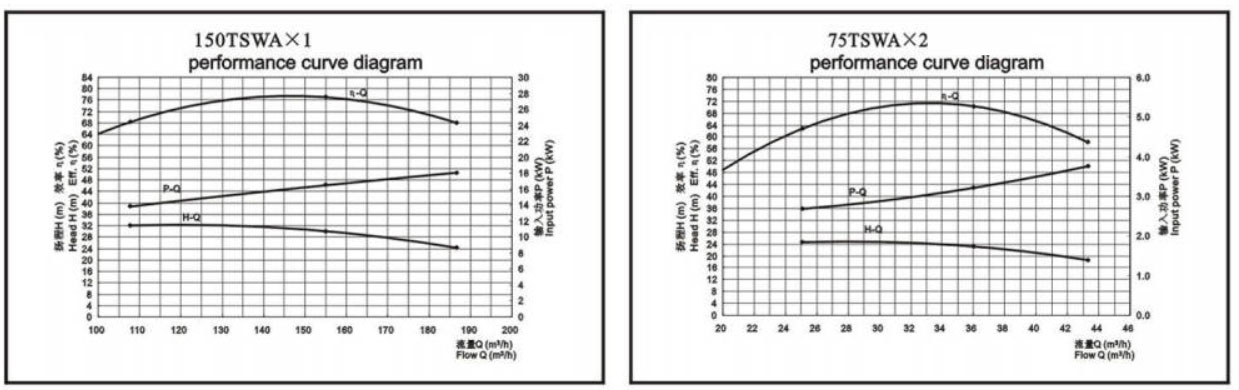

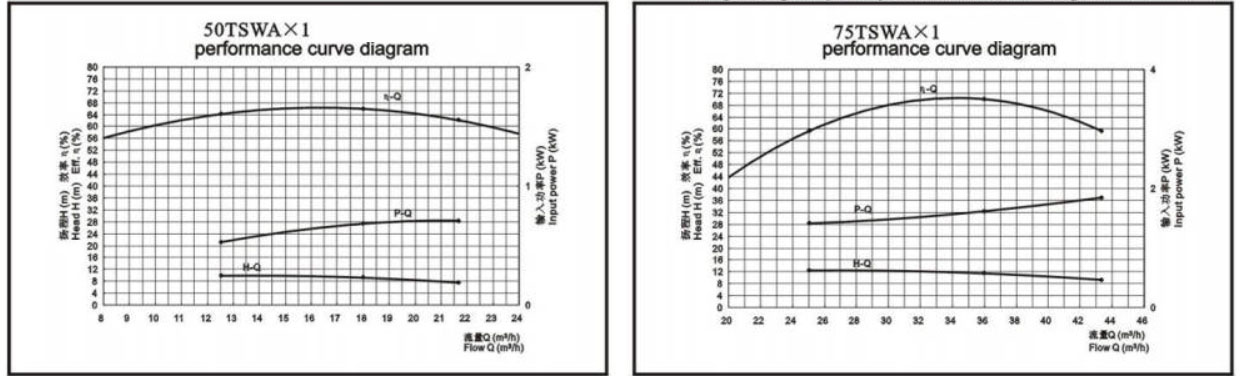

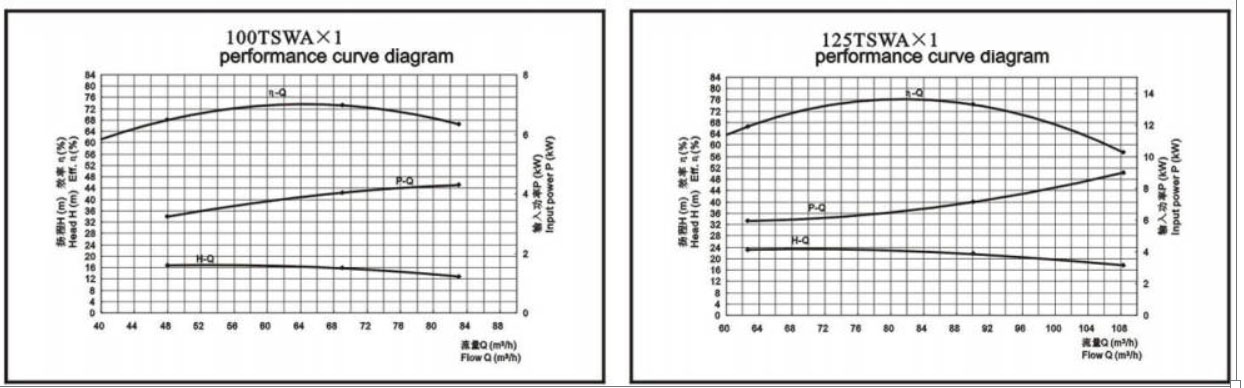

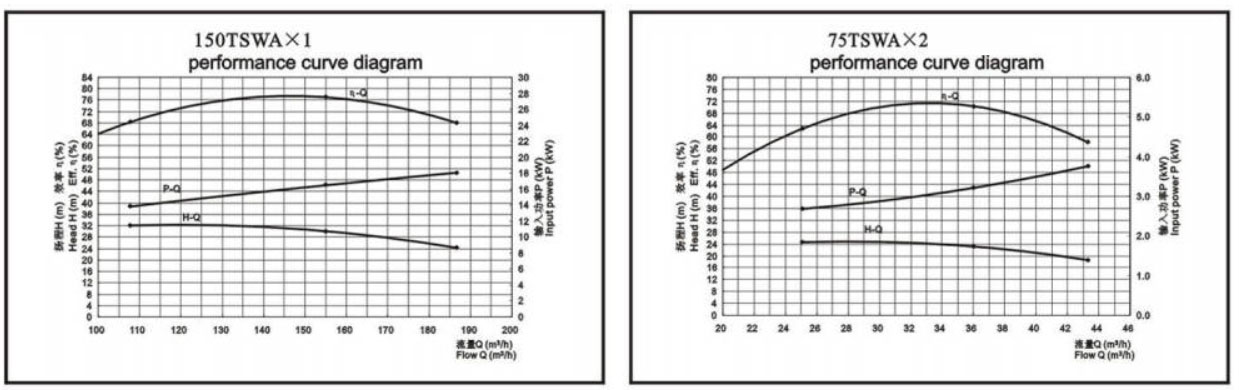

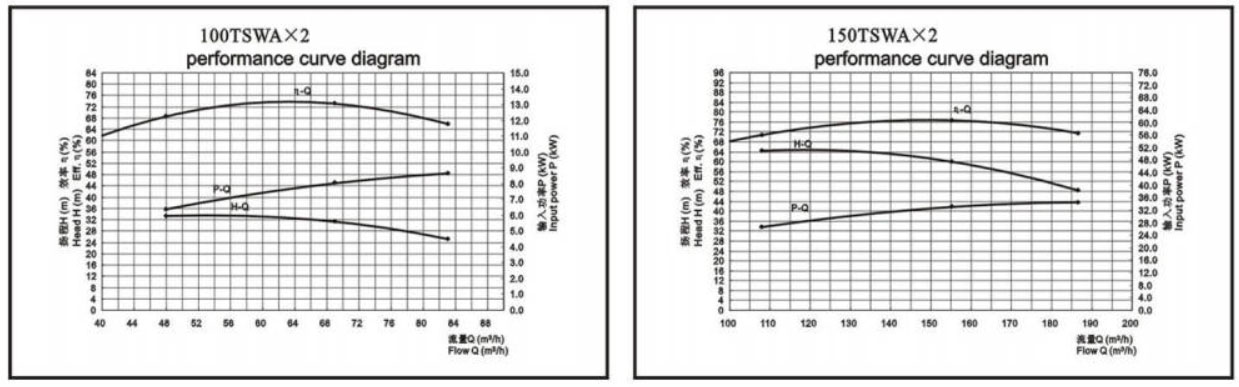

Performance Curves

Installation Diagrams

Installation Dimensions

|

Model

|

Stages

|

Pump Dimensions (H2=B)

|

Baseplate dimensions

|

Flange Dimensions

|

||||||||||||

|

L

|

L1

|

L2

|

B

|

H3

|

L3

|

L4

|

L5

|

B1

|

B2

|

4-φb

|

D

|

D1

|

Dn

|

n-φd

|

||

|

50TSWA18-9.2*2

|

2

|

1087

|

160

|

145

|

230

|

480

|

901

|

600

|

33

|

335

|

430

|

4-φ25

|

160

|

125

|

50

|

4-φ18

|

|

50TSWA18-9.2*3

|

3

|

1152

|

225

|

210

|

230

|

480

|

901

|

600

|

33

|

335

|

430

|

4-φ25

|

160

|

125

|

50

|

4-φ18

|

|

50TSWA18-9.2*4

|

4

|

1237

|

290

|

275

|

230

|

480

|

974

|

640

|

128

|

375

|

430

|

4-φ25

|

160

|

125

|

50

|

4-φ18

|

|

50TSWA18-9.2*5

|

5

|

1377

|

355

|

340

|

230

|

490

|

1153

|

740

|

132

|

430

|

430

|

4-φ25

|

160

|

125

|

50

|

4-φ18

|

|

50TSWA18-9.2*6

|

6

|

1442

|

420

|

405

|

230

|

490

|

1153

|

740

|

197

|

430

|

430

|

4-φ25

|

160

|

125

|

50

|

4-φ18

|

|

50TSWA18-9.2*7

|

7

|

1547

|

485

|

470

|

230

|

490

|

1321

|

840

|

197

|

430

|

430

|

4-φ25

|

160

|

125

|

50

|

4-φ18

|

|

50TSWA18-9.2*8

|

8

|

1612

|

550

|

535

|

230

|

490

|

1321

|

840

|

262

|

430

|

430

|

4-φ25

|

160

|

125

|

50

|

4-φ18

|

|

50TSWA18-9.2*9

|

9

|

1677

|

615

|

600

|

230

|

490

|

1386

|

860

|

297

|

430

|

430

|

4-φ25

|

160

|

125

|

50

|

4-φ18

|

|

50TSWA18-9.2*10

|

10

|

1827

|

680

|

665

|

230

|

490

|

1593

|

900

|

362

|

430

|

430

|

4-φ25

|

160

|

125

|

50

|

4-φ18

|

|

50TSWA18-9.2*11

|

11

|

1930

|

745

|

730

|

230

|

490

|

1593

|

1000

|

427

|

430

|

430

|

4-φ25

|

160

|

125

|

50

|

4-φ18

|

|

50TSWA18-9.2*12

|

12

|

1957

|

810

|

795

|

230

|

490

|

1658

|

1200

|

462

|

430

|

430

|

4-φ25

|

160

|

125

|

50

|

4-φ18

|

|

Model

|

Stages

|

Pump Dimensions (H2=B)

|

Baseplate dimensions

|

Flange Dimensions

|

||||||||||||

|

L

|

L1

|

L2

|

B

|

H3

|

L3

|

L4

|

L5

|

B1

|

B2

|

4-φb

|

D

|

D1

|

Dn

|

n-φd

|

||

|

75TSWA36-11.5*2

|

2

|

1241

|

177

|

180

|

250

|

535

|

1046

|

690

|

89

|

410

|

475

|

4-φ25

|

195

|

160

|

80

|

4-φ18

|

|

75TSWA36-11.5*3

|

3

|

1361

|

257

|

260

|

250

|

545

|

1046

|

690

|

128

|

410

|

475

|

4-φ25

|

195

|

160

|

80

|

4-φ18

|

|

75TSWA36-11.5*4

|

4

|

1526

|

337

|

340

|

250

|

545

|

1284

|

830

|

171

|

475

|

475

|

4-φ25

|

195

|

160

|

80

|

4-φ18

|

|

75TSWA36-11.5*5

|

5

|

1606

|

417

|

420

|

250

|

545

|

1284

|

830

|

211

|

475

|

475

|

4-φ25

|

195

|

160

|

80

|

4-φ18

|

|

75TSWA36-11.5*6

|

6

|

1731

|

497

|

500

|

250

|

545

|

1488

|

980

|

245

|

475

|

475

|

4-φ25

|

195

|

160

|

80

|

4-φ18

|

|

75TSWA36-11.5*7

|

7

|

1811

|

577

|

580

|

250

|

545

|

1488

|

980

|

245

|

475

|

475

|

4-φ25

|

195

|

160

|

80

|

4-φ18

|

|

75TSWA36-11.5*8

|

8

|

1916

|

657

|

660

|

250

|

560

|

1653

|

1150

|

239

|

480

|

480

|

4-φ25

|

195

|

160

|

80

|

4-φ18

|

|

75TSWA36-11.5*9

|

9

|

1996

|

737

|

740

|

250

|

560

|

1653

|

1150

|

239

|

480

|

480

|

4-φ25

|

195

|

160

|

80

|

4-φ18

|

|

75TSWA36-11.5*10

|

10

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

|

75TSWA36-11.5*11

|

11

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

|

Model

|

Stages

|

Pump Dimensions (H2=B)

|

Baseplate dimensions

|

Flange Dimensions

|

||||||||||||

|

L

|

L1

|

L2

|

B

|

H3

|

L3

|

L4

|

L5

|

B1

|

B2

|

4-φb

|

D

|

D1

|

Dn

|

n-φd

|

||

|

100TSWA69-15.6*2

|

2

|

1575

|

255

|

200

|

310

|

610

|

1322

|

900

|

100

|

505

|

505

|

4-φ30

|

230

|

190

|

100

|

8-φ23

|

|

100TSWA69-15.6*3

|

3

|

1720

|

355

|

300

|

310

|

610

|

1322

|

900

|

149

|

505

|

505

|

4-φ30

|

230

|

190

|

100

|

8-φ23

|

|

100TSWA69-15.6*4

|

4

|

1885

|

455

|

400

|

310

|

610

|

1463

|

975

|

200

|

505

|

505

|

4-φ30

|

230

|

190

|

100

|

8-φ23

|

|

100TSWA69-15.6*5

|

5

|

2050

|

555

|

500

|

310

|

620

|

1701

|

1240

|

202

|

525

|

525

|

4-φ30

|

230

|

190

|

100

|

8-φ23

|

|

100TSWA69-15.6*6

|

6

|

2150

|

655

|

600

|

310

|

620

|

1701

|

1240

|

157

|

525

|

525

|

4-φ30

|

230

|

190

|

100

|

8-φ23

|

|

100TSWA69-15.6*7

|

7

|

2295

|

755

|

700

|

310

|

630

|

1959

|

1450

|

198

|

565

|

565

|

4-φ30

|

230

|

190

|

100

|

8-φ23

|

|

100TSWA69-15.6*8

|

8

|

2420

|

855

|

800

|

310

|

640

|

1959

|

1450

|

199

|

565

|

565

|

4-φ30

|

230

|

190

|

100

|

8-φ23

|

|

100TSWA69-15.6*9

|

9

|

2520

|

955

|

900

|

310

|

640

|

2059

|

1550

|

199

|

565

|

565

|

4-φ30

|

230

|

190

|

100

|

8-φ23

|

|

100TSWA69-15.6*10

|

10

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

|

Model

|

Stages

|

Pump Dimensions (H2=B)

|

Baseplate dimensions

|

Flange Dimensions

|

||||||||||||

|

L

|

L1

|

L2

|

B

|

H3

|

L3

|

L4

|

L5

|

B1

|

B2

|

4-φb

|

D

|

D1

|

Dn

|

n-φd

|

||

|

125TSWA90-21.6*2

|

2

|

1740

|

270

|

205

|

320

|

670

|

1312

|

990

|

220

|

500

|

500

|

4-φ30

|

270

|

220

|

125

|

8-φ25

|

|

125TSWA90-21.6*3

|

3

|

1890

|

370

|

305

|

320

|

670

|

1449

|

1000

|

230

|

500

|

500

|

4-φ30

|

270

|

220

|

125

|

8-φ25

|

|

125TSWA90-21.6*4

|

4

|

2060

|

470

|

405

|

320

|

680

|

1603

|

1100

|

240

|

520

|

520

|

4-φ30

|

270

|

220

|

125

|

8-φ25

|

|

125TSWA90-21.6*5

|

5

|

2250

|

570

|

505

|

320

|

695

|

1774

|

1170

|

270

|

570

|

520

|

4-φ30

|

270

|

220

|

125

|

8-φ25

|

|

125TSWA90-21.6*6

|

6

|

2420

|

670

|

605

|

320

|

725

|

2005

|

1260

|

305

|

630

|

520

|

4-φ30

|

270

|

220

|

125

|

8-φ25

|

|

125TSWA90-21.6*7

|

7

|

2520

|

770

|

705

|

320

|

725

|

2005

|

1260

|

305

|

630

|

520

|

4-φ30

|

270

|

220

|

125

|

8-φ25

|

|

125TSWA90-21.6*8

|

8

|

2670

|

870

|

805

|

320

|

725

|

2243

|

1430

|

305

|

630

|

570

|

4-φ30

|

270

|

220

|

125

|

8-φ25

|

|

125TSWA90-21.6*9

|

9

|

2770

|

970

|

905

|

320

|

725

|

2243

|

1430

|

305

|

630

|

520

|

4-φ30

|

270

|

220

|

125

|

8-φ25

|

|

125TSWA90-21.6*10

|

10

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

|

Model

|

Stages

|

Pump Dimensions (H2=B)

|

Baseplate dimensions

|

Flange Dimensions

|

||||||||||||

|

L

|

L1

|

L2

|

B

|

H3

|

L3

|

L4

|

L5

|

B1

|

B2

|

4-φb

|

D

|

D1

|

Dn

|

n-φd

|

||

|

150TSWA155-30*2

|

2

|

1964

|

236

|

237

|

350

|

720

|

1437

|

1000

|

80

|

720

|

575

|

4-φ30

|

280

|

240

|

150

|

8-φ23

|

|

150TSWA155-30*3

|

3

|

2234

|

350

|

352

|

350

|

735

|

1735

|

1165

|

148

|

735

|

675

|

4-φ30

|

280

|

240

|

150

|

8-φ23

|

|

150TSWA155-30*4

|

4

|

2399

|

465

|

467

|

350

|

745

|

1922

|

1260

|

215

|

745

|

675

|

4-φ30

|

280

|

240

|

150

|

8-φ23

|

|

150TSWA155-30*5

|

5

|

2664

|

580

|

582

|

350

|

780

|

2129

|

1470

|

212

|

780

|

765

|

4-φ30

|

280

|

240

|

150

|

8-φ23

|

|

150TSWA155-30*6

|

6

|

2829

|

695

|

697

|

350

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

|

150TSWA155-30*7

|

7

|

2944

|

810

|

812

|

350

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

|

150TSWA155-30*8

|

8

|

3019

|

925

|

927

|

350

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

|

150TSWA155-30*9

|

9

|

3224

|

1040

|

1042

|

350

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

/

|

OEM & Custom

Chaodun Pump offers OEM and ODM customization for TSWA series pumps. Options include material upgrades (cast iron/stainless steel), mechanical seal type, flange standard (ANSI/DIN), and personalized packaging. Suitable for distributors and engineering contractors worldwide.

FAQs

- What applications is the TSWA pump suitable for?

The TSWA pump is ideal for high-rise water supply, firefighting, HVAC, and industrial water treatment. - What is the temperature limit of the liquid?

Maximum working temperature is 80°C for clean or mildly hot water. - Can the pump be customized for different voltages and frequencies?

Yes, it supports custom voltages and 50Hz/60Hz frequencies. - Does Chaodun Pump support OEM branding?

Yes, including logo, color, and packaging customization. - What certifications are available?

ISO9001 and CE certified, ensuring international quality standards. - What is the maximum flow rate and head for the TSWA pump?

Customizable flow rates and heads based on application needs. - What is the recommended maintenance for the pump?

Regular filter checks and seal replacements for efficient operation. - Is the TSWA pump suitable for handling corrosive liquids?

Yes, made with corrosion-resistant materials, ideal for chemical media and sewage.