Product Overview

The W/-HY Firefighting Pressure Stabilizing Water Supply Equipment is a new type of pressure-boosting and stabilizing equipment, developed and designed in accordance with the Ministry of Construction of the People’s Republic of China’s [1996] 108 document from August 1996 and in compliance with the 98S205 (formerly 98S176) standard. This equipment is specifically designed to address the issue where high-position firewater tanks in temporary high-pressure firefighting water systems cannot meet the required pressure for disadvantaged points, providing a solution for firefighting and domestic water supply systems.

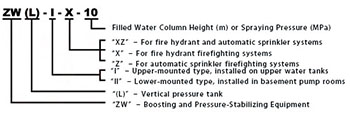

Model Designation

Key Features

-

The unique single or double-blade impeller design significantly enhances solid particle handling capabilities, enabling the processing of fiber materials up to 5 times and particles with about 50% of the intake hole size.

-

Advanced corrosion-resistant hard alloy mechanical seals provide continuous operation for over 8000 hours.

-

Compact structure, small footprint, low noise, and easy maintenance. The equipment can operate normally even when fully submerged, eliminating the need for a pump room, thus significantly reducing costs in civilian construction.

-

The sealing oil chamber is equipped with high-precision interference-resistant leak sensors, and a thermal protection film is embedded in the line group of the positioning device to ensure automatic motor protection.

-

Optional fully automatic control panel that effectively prevents leaks, overloads, overheating, and other operational failures, enhancing the safety and reliability of the system.

-

The floating switch automatically starts and stops the pump based on changes in water levels, requiring no manual operation.

-

The WQ series can be equipped with a dual-shaft automatic linkage system, making installation and maintenance easier, without the need for wastewater to enter the pump pit.

Engineering Summary

This equipment is suitable for fire hydrant water supply systems and wet automatic sprinkler fire suppression systems in multi-story and high-rise buildings, as well as other firefighting and domestic water supply systems that require pressure boosting. The equipment consists of a diaphragm-type pressure tank, pressure stabilizing pumps, an electric control box, instruments, and pipeline accessories. It is designed in strict accordance with the Fire Protection Design Code for Civil Buildings GB50045-95, Pressure Water Supply Design Code, and CECS76:95.

Applications

The equipment is widely used in various firefighting and domestic water supply systems, particularly in multi-story and high-rise buildings where pressure boosting is required for fire hydrant water supply systems and wet automatic sprinkler fire suppression systems.

System Configuration

-

Diaphragm-Type Pressure Tank: Provides stable water pressure and buffering functions.

-

Pressure Stabilizing Pumps: Ensures the system remains stable under varying pressure conditions.

-

Electric Control Box: Automatically adjusts and starts the pump system to ensure the pressure meets firefighting requirements.

System Components

-

Pressure Tank: The capacity meets the firefighting water demand, providing necessary pressure stabilization and buffering volumes.

-

Pressure Stabilizing Pumps: One primary and one backup pump ensure efficient and stable operation.

-

Electric Control System: Supports both automatic and manual operation, ensuring the system responds quickly in the event of a fire.

Design Fundamentals

The design of this equipment complies with firefighting water supply system standards, providing adequate water flow and pressure while ensuring stable operation in high-pressure environments. It meets the needs of various firefighting and domestic water supply applications.

Selection and Operational Principles

Pressure and Flow Requirements

-

-

Pressure Control: The system controls the start and stop of the pressure tank by setting pressures P1, P2, Ps1, and Ps2, ensuring stable operation during the firefighting process.

-

Flow Requirements: The design should be based on the required firefighting flow during the initial stages of a fire, ensuring it meets the needs of various systems.

-

Demand Applications

-

Fire Hydrant Systems: The water flow in the fire hydrant system ranges from 2.5 GPM to 5 GPM, meeting the requirements for different spray lengths.

-

Automatic Sprinkler Systems: Each sprinkler head has a flow rate of 1.0 GPM, ensuring effective fire suppression.

Intermittent Applications

Suitable for applications that require intermittent pressurization, such as temporary firefighting water supply systems during off-peak hours.

Operational Principles

The equipment ensures stable operation and automatically adjusts based on pressure changes to meet firefighting needs while maintaining long-term stable operation.

Technical Conditions

Technical Specifications

-

Operating pressure range: 0.6MPa, 1.0MPa, 1.6MPa, with pressure tank storage and stabilizing water volumes meeting firefighting system requirements.

-

Dual liquid-level float control system ensures precise water level control.

Service Conditions

-

Operating temperature: 5°C to 40°C

-

Water source requirements: Compatible with high-position water tanks or bottom-level water pools.

Environmental Requirements

The equipment operates stably under typical temperature and humidity conditions and is suitable for the majority of environments.

Electric Control Functions

The electric control system has both automatic and manual operation functions and supports integration with the firefighting control center, ensuring rapid response in the event of a fire.

Operating Instructions

The operating system is user-friendly, with detailed operating manuals and maintenance guides to ensure the equipment operates efficiently and remains stable.

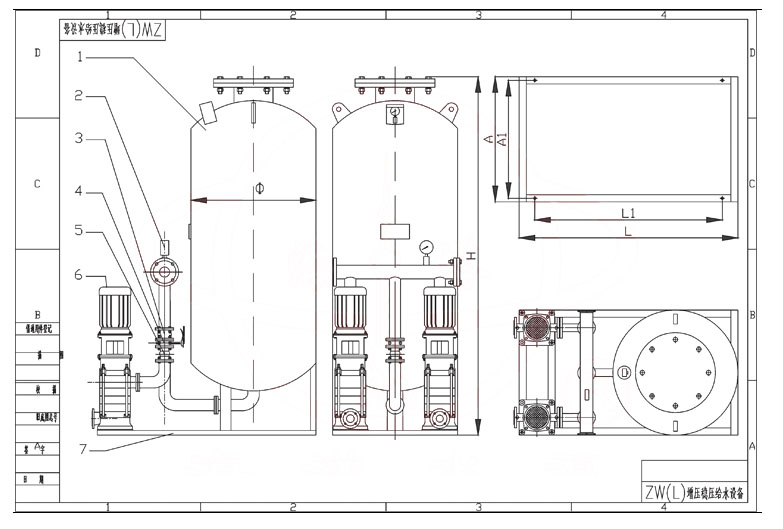

Installation & Dimensions

Outline Drawing

Performance Data

Performance Data

|

|

|

Performance Parameters

|

No.

|

Booster & Pressure-Stabilizing Unit Model

|

Fire Pressure P1 (MPa)

|

Vertical Diaphragm Pressure Tank

|

Matched Pump

|

Operating Weight (kg)

|

Operating Pressure (MPa)

|

Pressure-Stabilizing Volume (L)

|

||||

|

Tank Model

|

Working Pressure Ratio

|

Fire Storage Volume (L)

|

Pump Model

|

||||||||

|

Rated Volume

|

Effective Volume

|

||||||||||

|

1

|

ZW(L)-I-X-7

|

0.1

|

SQL800*0.6

|

0.60

|

300

|

319

|

25LG3-10*4 1.5 kW

|

1452

|

P1=0.10 Ps1=0.26 P2=0.23 Ps2=0.31

|

54

|

|

|

2

|

ZW(L)-I-Z-10

|

0.16

|

SQL800*0.6

|

0.80

|

150

|

159

|

25LG3-10*4 1.5 kW

|

1428

|

P1=0.16 Ps1=0.26 P2=0.23 Ps2=0.31

|

70

|

|

|

3

|

ZW(L)-I-X-10

|

0.16

|

SQL800*0.6

|

0.60

|

300

|

319

|

25LG3-10*5 1.5 kW

|

1474

|

P1=0.16 Ps1=0.36 P2=0.33 Ps2=0.42

|

52

|

|

|

4

|

ZW(L)-I-X-13

|

0.22

|

SQL1000*0.6

|

0.76

|

300

|

329

|

25LG3-10*4 1.5 kW

|

2312

|

P1=0.22 Ps1=0.35 P2=0.32 Ps2=0.40

|

97

|

|

|

5

|

ZW(L)-XZ-10

|

0.16

|

SQL1000*0.6

|

0.65

|

450

|

480

|

25LG3-10*4 1.5 kW

|

2312

|

P1=0.16 Ps1=0.33 P2=0.30 Ps2=0.38

|

86

|

|

|

6

|

ZW(L)-XZ-13

|

0.22

|

SQL1000*0.6

|

0.67

|

450

|

452

|

25LG3-10*5 1.5 kW

|

2312

|

P1=0.22 Ps1=0.41 P2=0.38 Ps2=0.46

|

80

|

|

|

7

|

ZW(L)-II-Z-

|

A

|

0.22-0.38

|

SQL800*0.6

|

0.80

|

150

|

159

|

25LG3-10*6 2.2 kW

|

1452

|

P1=0.38 Ps1=0.53 P2=0.50 Ps2=0.60

|

61

|

|

8

|

ZW(L)-II-Z-

|

B

|

0.38-0.50

|

SQL800*1.0

|

0.80

|

150

|

159

|

25LG3-10*8 2.2 kW

|

1513

|

P1=0.50 Ps1=0.68 P2=0.65 Ps2=0.75

|

51

|

|

9

|

ZW(L)-II-Z-

|

C

|

0.50-0.65

|

SQL1000*1.6

|

0.85

|

150

|

206

|

25LG3-10*9 2.2 kW

|

1653

|

P1=0.65 Ps1=0.81 P2=0.78 Ps2=0.86

|

59

|

|

10

|

ZW(L)-II-Z-

|

D

|

0.65-0.85

|

SQL1000*1.6

|

0.85

|

150

|

206

|

25LG3-10*11 3 kW

|

1701

|

P1=0.85 Ps1=1.04 P2=1.02 Ps2=1.10

|

57

|

|

11

|

ZW(L)-II-Z-

|

E

|

0.85-1.00

|

SQL1000*1.6

|

0.85

|

150

|

206

|

25LG3-10*13 4 kW

|

1709

|

P1=1.00 Ps1=1.21 P2=1.19 Ps2=1.27

|

50

|

|

No.

|

Booster & Pressure-Stabilizing Unit Model

|

Fire Pressure P1 (MPa)

|

Vertical Diaphragm Pressure Tank

|

Matched Pump

|

Operating Weight (kg)

|

Operating Pressure (MPa)

|

Pressure-Stabilizing Volume (L)

|

||||

|

Tank Model

|

Working Pressure Ratio

|

Fire Storage Volume (L)

|

Pump Model

|

||||||||

|

Rated Volume

|

Effective Volume

|

||||||||||

|

12

|

ZW(L)-II-X-

|

A

|

0.22-0.38

|

SQL1000*0.6

|

0.78

|

300

|

302

|

25LG3-10*6 2.2 kW

|

2344

|

P1=0.38 Ps1=0.55 P2=0.52 Ps2=0.60

|

72

|

|

13

|

ZW(L)-II-X-

|

B

|

0.38-0.50

|

SQL1000*1.0

|

0.78

|

300

|

302

|

25LG3-10*8 2.2 kW

|

2494

|

P1=0.50 Ps1=0.70 P2=0.67 Ps2=0.75

|

61

|

|

14

|

ZW(L)-II-X-

|

C

|

0.50-0.65

|

SQL1000*1.6

|

0.78

|

300

|

302

|

25LG3-10*10 3 kW

|

2689

|

P1=0.65 Ps1=0.88 P2=0.86 Ps2=0.93

|

51

|

|

15

|

ZW(L)-II-X-

|

D

|

0.65-0.85

|

SQL1000*1.6

|

0.85

|

300

|

355

|

25LG3-10*13 4 kW

|

2703

|

P1=0.85 Ps1=1.05 P2=1.02 Ps2=1.10

|

82

|

|

16

|

ZW(L)-II-X-

|

E

|

0.85-1.00

|

SQL1000*1.6

|

0.88

|

300

|

355

|

25LG3-10*15 4 kW

|

2730

|

P1=1.00 Ps1=1.21 P2=1.19 Ps2=1.26

|

73

|

|

17

|

ZW(L)-II-XZ-

|

A

|

0.22-0.38

|

SQL1200*0.6

|

0.80

|

450

|

474

|

25LG3-10*6 2.2 kW

|

3641

|

P1=0.38 Ps1=0.53 P2=0.50 Ps2=0.58

|

133

|

|

18

|

ZW(L)-II-XZ-

|

B

|

0.38-0.50

|

SQL1200*1.0

|

0.80

|

450

|

474

|

25LG3-10*8 2.2 kW

|

3947

|

P1=0.50 Ps1=0.68 P2=0.65 Ps2=0.73

|

110

|

|

19

|

ZW(L)-II-XZ-

|

C

|

0.50-0.65

|

SQL1200*1.6

|

0.80

|

450

|

474

|

25LG3-10*10 3 kW

|

3961

|

P1=0.65 Ps1=0.87 P2=0.84 Ps2=0.92

|

90

|

|

20

|

ZW(L)-II-XZ-

|

D

|

0.65-0.85

|

SQL1200*1.6

|

0.80

|

450

|

474

|

25LG3-10*12 4 kW

|

4124

|

P1=0.85 Ps1=1.12 P2=1.09 Ps2=1.17

|

73

|

|

21

|

ZW(L)-II-XZ-

|

E

|

0.85-1.00

|

SQL1200*1.6

|

0.80

|

450

|

474

|

25LG3-10*14 4 kW

|

4156

|

P1=1.00 Ps1=1.30 P2=1.27 Ps2=1.35

|

64

|

|

Note:

|

|||||||||||

Operating Manual

Precautions

-

Power Supply and Cable Check

The power supply for this pump must be a three-phase, four-wire system. If there is no ground wire, one must be added to prevent electric leakage. During operation, a circuit fuse and switch compatible with the motor must be installed near the motor to prevent motor damage in case the impeller is blocked by foreign materials. -

Pump Installation

The pump does not require a fixed foundation and can operate securely by leaning against a firm support. If necessary, tie it with a rope to prevent accidents. After starting, always check the motor rotation direction; reverse rotation should not exceed one minute. -

Handling Foreign Materials

If the pumped liquid contains a significant amount of debris such as weeds, iron wire, wood, bricks, etc., remove them as much as possible before use. A wire basket or similar device can be installed to prevent debris from entering the pump, which could cause impeller damage, jamming, or pipeline blockages. -

Pump Flushing and Maintenance

After pumping mud or other contaminants, perform a short water intake operation to flush the pump body and pipeline, ensuring cleanliness.

Operation & Running

-

Motor and Pump Inspection

Before starting, check the motor stator’s insulation resistance with a megohmmeter. Ensure the voltage is within ±10% of the rated value. Inspect the power cable for any damage and ensure the cable’s cross-sectional area matches the current. -

Rotor and Pump Direction

Inspect the rotor rotation direction. Ensure it rotates clockwise when viewed from the motor side. Reverse rotation must not exceed one minute to avoid damaging the pump and motor. -

Pump After Long-Term Idle

For pumps that have been idle for a long time, inspect and clean the pump components, and apply anti-rust oil to all sliding and mating surfaces before storage in a dry place. -

Pump Operation and Safety

During operation, regularly check the pump and motor status. The bearing temperature should not exceed 75°C. If abnormal vibration or noise is detected, immediately stop the pump and troubleshoot. Ensure the oil level is maintained within the correct range, and if the pump performance drops significantly, replace the rubber stator.

Pump Body & Pipeline Fit

-

Inlet Pipe and Pump Body Compatibility

The suction pipe should avoid sharp bends. Ensure the pipeline is downward inclined (about 30°) to facilitate air release. -

Discharge Pipe Support

The discharge pipeline should be independently supported by its own bracket. The pump body must not bear the weight of the pipeline, as this may cause deformation and affect performance. -

Pump Installation Location

Ensure the installation location is spacious for easy operation and maintenance. For better self-priming, place the pump inlet at the lowest possible water level. -

Inlet Filter Installation

Install a filter at the inlet of the pump. The filter’s effective cross-sectional area should be 2-3 times the area of the suction pipe to prevent debris from entering the pump.

Operation & Troubleshooting

-

Scheduled Maintenance

After about 1,250 hours of operation, perform scheduled maintenance, including disassembling the pump base, checking the bearings and seals, cleaning, and replacing grease. Replace oil seals, shaft sleeves, and other parts as needed. For pumps using mechanical seals, regular maintenance is required after approximately 3,500 hours of operation. -

Addressing Abnormalities

If abnormalities such as failure to start, tripped protection devices, or blown fuses occur during operation, immediately disconnect the power supply and inspect the protection devices. If external devices are functioning properly, the issue might be within the pump, and it should be repaired before further use to avoid accidents. -

Avoid Overloading and Overheating

When handling thick sludges, viscous liquids, or transporting slurry over long distances or high heads, load conditions may change. However, increasing the load by altering the pump structure is not allowed. Regularly inspect the system to prevent overloading or overheating of the motor.

OEM & Custom

Chaodun Pump offers OEM and ODM customization for W-HY fire pressure stabilizing systems, including tank capacity, pressure range, and control configuration. All products are factory tested, CE-certified, and meet ISO9001 standards for export use.

FAQs

- Q1: What is the W-HY Fire Pressure Boosting & Stabilizing Equipment used for?

It maintains steady pressure in hydrant and sprinkler systems, ensuring reliable fire protection. - Q2: Can it operate automatically?

Yes, it uses pressure sensors to control automatic pump start/stop cycles. - Q3: What’s the difference between I-type and II-type?

I-type is installed near upper tanks, II-type near pump rooms or reservoirs. - Q4: Is customization available?

Yes, we offer OEM solutions for flow, head, and control system design. - Q5: What certifications does it have?

GB50045-95, CECS76:95, ISO9001, and CE export certifications. - Q6: What is the lifespan of the diaphragm air tank?

Over 10 years with minimal maintenance. - Q7: Does Chaodun Pump provide installation guidance?

Yes, full documentation, installation diagrams, and remote support are available.