Product Overview

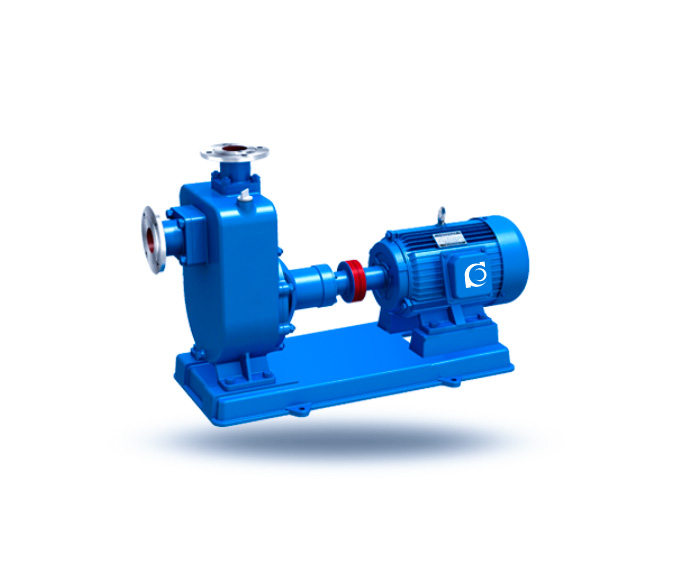

The ZX Transparent Water Centrifugal Self-Priming Pump is a self-priming centrifugal pump, designed with an axial recirculation pump casing structure.

The pump does not require a foot valve in the suction line and retains a fixed volume of liquid inside the pump casing before startup to achieve self-priming. This design simplifies the piping system and improves operational conditions.

The pump is compact, operates stably, has high efficiency, and a long service life, making it widely suitable for the transfer of clean or lightly contaminated aqueous fluids.

Model Designation

Key Features

Key Features

-

Powerful Self-Priming Capability: No foot valve required, simplifying the system design and improving self-priming efficiency.

-

Compact Design: Saves space, is easy to install and maintain, and is structurally reliable.

-

High Efficiency & Long Lifespan: Efficient operation with excellent durability, adaptable to different operational environments.

-

Wide Applicability: Suitable for various clean or lightly contaminated fluid transfer applications, including water, chemicals, and light slurries.

Engineering Summary

The ZX Self-Priming Pump uses centrifugal force generated by the impeller to continuously mix, separate, and circulate liquid and air.

During startup, air in the suction pipeline is gradually expelled through repeated gas-liquid separation and circulation, allowing the pump to complete the self-priming process and stabilize its operation.

This self-priming mechanism does not require auxiliary equipment, making it ideal for systems that frequently start and stop or operate under fluctuating conditions.

Typical Applications

The ZX Self-Priming Pump is widely used in various industries and operational scenarios, including:

-

Municipal Environmental Protection, Building and Fire Systems

-

Chemical, Pharmaceutical, Dyeing, Printing, Papermaking, and Electroplating

-

Oil, Mining, Equipment Cooling, and Tanker Discharge

-

Agricultural Spraying: Used in farms, nurseries, orchards, and tea gardens

-

Spray Conveyance for Filtration Applications: Used in filtration presses

The pump is suitable for handling clean water, seawater, acidic or alkaline chemical media, with a viscosity ≤100 cP and solid content up to 30% in slurries.

System Configuration

The ZX Transparent Water Centrifugal Self-Priming Pump primarily consists of:

-

Suction Chamber

-

Liquid Storage Chamber

-

Pump Casing and Recirculation Channel

-

Gas-Liquid Separation Chamber

-

Conveyance Unit Assembly

-

Bearing Casing and Sealing Components

-

(Optional) Bearing Cooling Chamber

Components and Supply

The pump components are made from corrosion-resistant, high-strength materials to ensure long-term stable operation. Major components include:

-

Pump Casing: Made of cast iron or stainless steel, offering excellent corrosion resistance and pressure performance.

-

Impeller: Optimized design to ensure fluid passage capability and self-priming performance.

-

Bearing System: Provides stable support, maintaining high efficiency after extended operation.

-

Sealing System: Features a dual-seal design to effectively prevent liquid leakage from high-pressure areas to low-pressure areas.

Technical Service

The ZX Self-Priming Pump provides comprehensive technical support and services, including:

-

Installation Guidance: Detailed installation manuals and on-site support.

-

Maintenance and Repairs: Regular maintenance and repair services to ensure efficient pump operation.

-

Technical Assistance: 24/7 technical support to resolve operational issues.

Operating Conditions

-

Ensure a fixed volume of liquid is retained in the pump casing before startup for self-priming.

-

The fluid being transported may contain small solids (≤30%).

-

Maximum allowable viscosity: ≤100 cP.

-

Bearing temperature should be monitored during continuous operation to ensure it remains within a safe range.

-

Suitable for general industrial and agricultural water or similar media.

Service Conditions

The ZX Self-Priming Pump performs well in harsh operating environments, adapting to fluctuating operational conditions.

-

Operating Ambient Temperature: Broad operational range, adaptable to various climates.

-

Humidity Tolerance: Suitable for high humidity environments, with the pump and motor designed for moisture resistance.

-

Flow and Pressure Fluctuations: The pump remains stable under varying flow and pressure conditions.

Protection Features

The ZX Self-Priming Pump is equipped with a comprehensive protection system, including:

-

Overload Protection: Prevents the pump from operating under excessive loads, protecting the equipment.

-

Overheat Protection: Automatically shuts down the pump if the temperature exceeds the set limit.

-

Dry-Run Protection: The system shuts down if the pump fails to prime due to insufficient liquid.

Selection Criteria

When selecting the ZX Self-Priming Pump, consider the following factors:

-

Flow Requirements: Determine the required flow range based on actual application.

-

Type of Media: Select the appropriate pump materials to handle different chemical media.

-

Operating Pressure: Ensure the pump’s maximum working pressure meets system requirements.

-

Operating Environment: Take into account ambient temperature, humidity, and other external factors affecting pump performance.

Specifications & Installation

Outline Drawing

Performance Data

|

1

|

Coupling

|

2

|

Pump Shaft

|

3

|

Bearing

|

4

|

Mechanical Seal

|

5

|

Bearing Housing

|

6

|

Pump Casing

|

7

|

Discharge Port

|

|

8

|

Inlet Port

|

9

|

Front Seal Ring

|

10

|

Impeller

|

11

|

Rear Cover

|

12

|

Water Baffle

|

13

|

Liquid Filling Hole

|

14

|

Liquid Return Hole

|

Performance Parameters

|

Model

|

Imported Pumps

|

In the Pump Industry

|

Suction Lift

|

Motor

|

Flow Rate (m³/h)

|

Head (m)

|

|

(mm)

|

(mm)

|

(m)

|

(KW)

|

(L/min)

|

(m)

|

|

|

25ZX3.2-20

|

25

|

25

|

6.5

|

0.75

|

3.2

|

20

|

|

25ZX3.2-32

|

25

|

25

|

6.5

|

1.1

|

3.2

|

32

|

|

40ZX6.3-20

|

40

|

32

|

6.5

|

1.1

|

6.3

|

20

|

|

40ZX10-40

|

40

|

40

|

6.5

|

4

|

10

|

40

|

|

50ZX15-12

|

50

|

50

|

6.5

|

1.5

|

15

|

12

|

|

50ZX18-20

|

50

|

50

|

6.5

|

2.2

|

18

|

20

|

|

50ZX12.5-32

|

50

|

50

|

6.5

|

3

|

12.5

|

32

|

|

50ZX20-30

|

50

|

50

|

6.5

|

4

|

20

|

30

|

|

50ZX14-35

|

50

|

50

|

6.5

|

4

|

14

|

35

|

|

50ZX10-40

|

50

|

50

|

6.5

|

4

|

10

|

40

|

|

50ZX12.5-50

|

50

|

50

|

6.5

|

5.5

|

12.5

|

50

|

|

50ZX15-60

|

50

|

50

|

6.5

|

7.5

|

15

|

60

|

|

50ZX20-75

|

50

|

50

|

6.5

|

11

|

20

|

75

|

|

Model

|

Imported Pumps

|

In the Pump Industry

|

Suction Lift

|

Motor

|

Flow Rate (m³/h)

|

Head (m)

|

|

(mm)

|

(mm)

|

(m)

|

(KW)

|

(L/min)

|

(m)

|

|

|

65ZX30-15

|

65

|

50

|

6.5

|

3

|

30

|

15

|

|

65ZX25-32

|

65

|

50

|

6

|

5.5

|

25

|

32

|

|

80ZX35-13

|

80

|

80

|

6

|

2.2

|

35

|

13

|

|

80ZX43-17

|

80

|

80

|

6

|

4

|

43

|

17

|

|

80ZX40-22

|

80

|

80

|

6

|

5.5

|

40

|

22

|

|

80ZX50-25

|

80

|

80

|

6

|

7.5

|

50

|

25

|

|

80ZX50-32

|

80

|

80

|

6

|

7.5

|

50

|

32

|

|

80ZX60-55

|

80

|

80

|

6

|

18.5

|

60

|

55

|

|

80ZX60-70

|

80

|

80

|

6

|

22

|

60

|

70

|

|

100ZX100-20

|

100

|

80

|

6

|

11

|

100

|

20

|

|

100ZX100-40

|

100

|

100

|

6

|

18.5

|

100

|

40

|

|

100ZX100-65

|

100

|

100

|

6

|

30

|

100

|

65

|

|

100ZX70-75

|

100

|

100

|

6

|

30

|

70

|

75

|

|

Model

|

Imported Pumps

|

In the Pump Industry

|

Suction Lift

|

Motor

|

Flow Rate (m³/h)

|

Head (m)

|

|

(mm)

|

(mm)

|

(m)

|

(KW)

|

(L/min)

|

(m)

|

|

|

150ZX170-55

|

150

|

150

|

5

|

45

|

170

|

55

|

|

150ZX170-65

|

150

|

150

|

5

|

55

|

170

|

65

|

|

150ZX160-80

|

150

|

150

|

5

|

55

|

160

|

80

|

|

200ZX400-32

|

200

|

200

|

5

|

55

|

400

|

32

|

|

200ZX280-63

|

200

|

200

|

5

|

90

|

280

|

63

|

|

200ZX350-65

|

200

|

200

|

5

|

110

|

350

|

65

|

|

250ZX550-32

|

250

|

250

|

5

|

75

|

550

|

32

|

|

250ZX400-50

|

250

|

250

|

5

|

90

|

400

|

50

|

|

250ZX450-55

|

250

|

250

|

5

|

110

|

450

|

55

|

|

250ZX400-75

|

250

|

250

|

5

|

132

|

400

|

75

|

|

300ZX600-32

|

300

|

300

|

5

|

90

|

600

|

32

|

|

300ZX500-50

|

300

|

300

|

5

|

110

|

500

|

50

|

|

300ZX550-55

|

300

|

300

|

5

|

132

|

550

|

55

|

Operating Manual

OEM & Custom

Supports OEM/ODM customization, special materials, voltage options, flange standards, customized color, private label branding and export packaging.

FAQs

- 1. What liquids can the ZX / ZXL pump handle?

Mainly clean water or liquids with similar physical properties. - 2. Does it need a bottom valve?

No. The pump is fully self-priming after initial filling. - 3. What is the maximum temperature?

0–80°C for clean water applications. - 4. Can it be used for irrigation?

Yes. The pump is widely used for agriculture and garden irrigation. - 5. Is installation complicated?

No. The pump has a simple and compact structure. - 6. What is the delivery time?

7–15 days depending on quantity. - 7. Do you supply spare parts?

Yes. Impellers, seals, wear rings and mechanical seals are available.